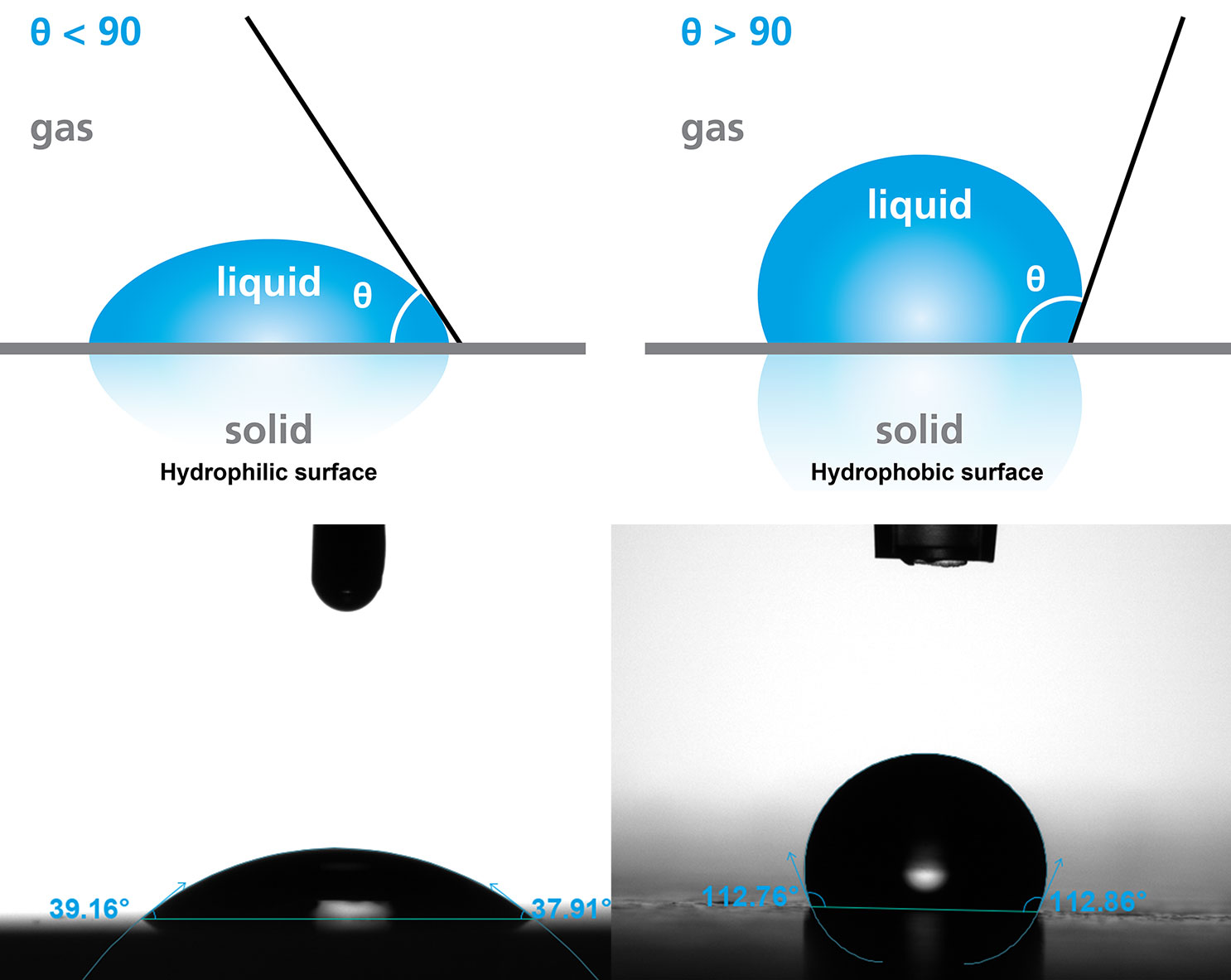

The contact angle is a fundamental measure of surface wettability—the tendency of a liquid to spread on or adhere to a solid surface. It is defined as the angle, measured through the liquid, at the point where the liquid-vapor interface meets the solid surface. This angle provides crucial insight into the surface energy and the nature of the solid-liquid interaction.

The Theoretical Foundation

The theoretical basis for the contact angle lies in the balance of interfacial tensions at the point of three-phase contact (solid, liquid, and vapor/air).

1. Young’s Theory (The Ideal Surface)

For a perfect, completely smooth and uniform surface, the final contact angle is determined by the relative strength of the attraction between the liquid and the solid compared to the internal cohesion of the liquid itself.

- If the liquid is strongly attracted to the solid (high solid-liquid affinity), it spreads out, and the angle is small (less than 90°). The surface is called hydrophilic (if the liquid is water).

- If the liquid is weakly attracted to the solid, it beads up into a sphere to minimize contact, and the angle is large (greater than 90°). The surface is called hydrophobic.

2. Wenzel Model (Roughness Amplifies)

Most real surfaces are rough. The Wenzel model applies when the liquid droplet manages to fill all the tiny grooves and crevices on the rough surface, making complete contact with the solid material.

In this scenario, the roughness simply amplifies the surface’s intrinsic nature:

- A surface that is naturally hydrophilic becomes even more hydrophilic (the angle gets smaller).

- A surface that is naturally hydrophobic becomes even more hydrophobic (the angle gets larger).

3. Cassie-Baxter Model (Floating on Air)

The Cassie-Baxter model applies when the surface is so rough or textured that the liquid droplet cannot penetrate the grooves. Instead, the droplet sits on a composite surface made up of the solid peaks and pockets of trapped air underneath.

In this state, the droplet is effectively “floating” on a layer of air. This configuration often results in superhydrophobicity (angles greater than 150°), leading to the “self-cleaning” effect observed in nature, like on a lotus leaf, because the droplet barely touches the solid material.

Application to 3D-Printed Resin Parts

In vat photopolymerization methods like Stereolithography (SLA) or Digital Light Processing (DLP), liquid resin is cured by light to form solid parts. The resulting surface properties, especially the contact angle, are crucial for the part’s performance in various applications.

- Influence of 3D Printing Parameters

The manufacturing process and component orientation during printing might have a influence on the surface morphology and, consequently, the contact angle:

- Layering and Stair-Stepping: 3D printing creates a layered structure. The inevitable “stair-step” effect due to finite layer thickness introduces roughness. This roughness contributes to the Wenzel or Cassie-Baxter state, altering the final contact angle.

- Print Orientation: The angle at which a part is printed relative to the build platform affects the visibility and size of layer lines, which might result in anisotropic (direction-dependent) wetting behavior.

- Post-Processing: Curing, cleaning, and surface treatments (like polishing or applying coatings) dramatically modify the surface chemistry and roughness, allowing for the tailoring of the contact angle.

- Importance in Engineering Applications

Understanding and controlling the contact angle of 3D-printed resin parts is vital for:

- Fluid Dynamics: In components like microfluidic devices, chemical reactors, or thermal separation columns, the wettability of the surfaces directly affects liquid distribution and flow characteristics. Computational Fluid Dynamics (CFD) simulations rely on accurate contact angle measurements as a key input.

- Biocompatibility: For medical devices and implants, the surface wettability determines how biological fluids (like blood) and cells interact with the material.

By precisely controlling the resin material, printing parameters, and post-processing, 3D printing allows engineers to design materials with tailored wetting properties, moving beyond the constraints of traditional manufacturing.

Contact angle of 3D-printed resins

The contact angle between water and 3D-printed resins was measured on 2 different materials:

1) Liqcreate Clear Impact in 2 print directions

2) Liqcreate Bio-Med Clear on 1 print direction

| Resin | Orientation | AC(M) [°] | AC(G) [°] | AC(D) [°] |

| Clear Impact | Vertical | 88,46 | 87,38 | 89,54 |

| Clear Impact | Horizontal | 82,50 | 83,11 | 81,89 |

| Bio-Med Clear | Horizontal | 76,49 | 76,04 | 76,94 |

From the results it can be seen that both materials are hydrophilic. There is little difference in contact angle measurement with water. The small differences indicate that Bio-Med Clear has the lowest contact angle in horizontal (only tested) orientation. Followed by Clear Impact 3D-printed in horizontal orientation. The one with the highest contact angle was Clear Impact, 3D-printed in vertical orientation.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Printer Settings →

Image by Nanoscience: contact angle measurement