Technical specifications

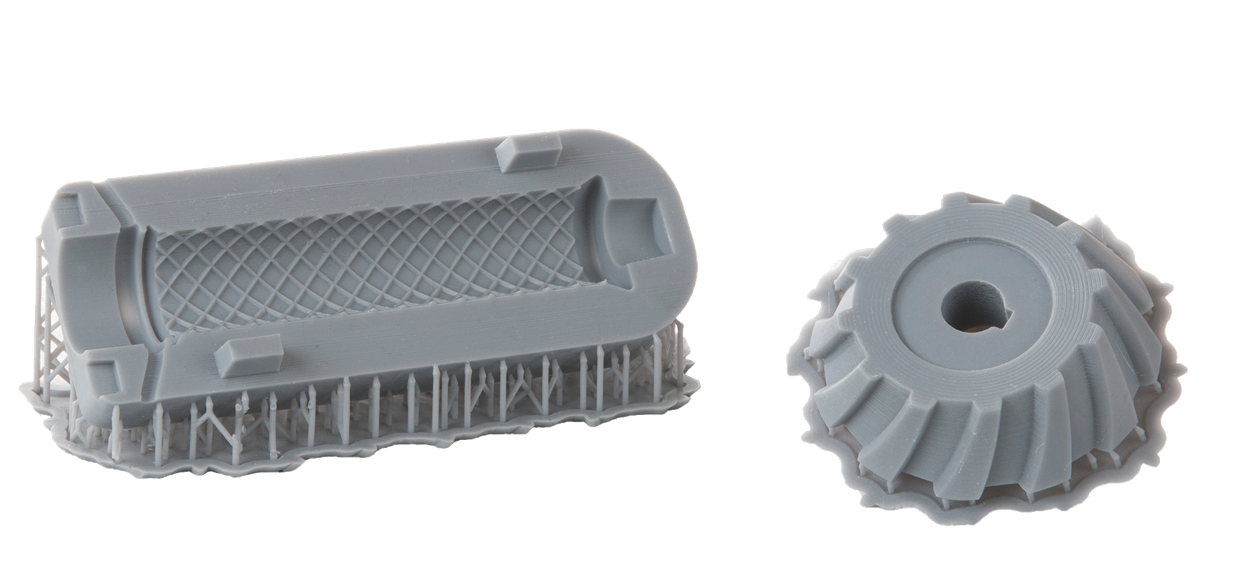

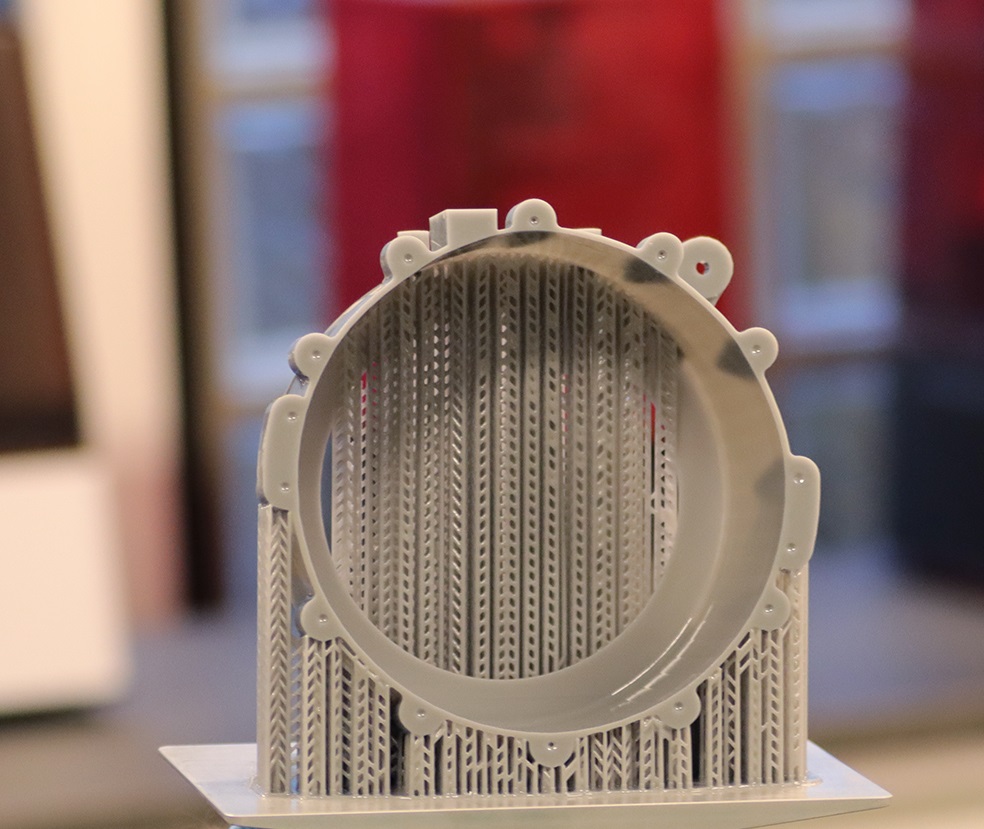

Liqcreate Strong-X is one of the strongest photopolymer resins available in the market. Its flexural strength of 135MPa, high stiffness and good short term temperature resistance which makes it ideal for injection molding and heavy duty applications.

| Mechanical Properties | UV post-curing[1] | ||

|---|---|---|---|

| Description | Method | High power LED curing

(30 minutes at 60°C) |

High power LED curing

(120 minutes at 60°C) |

| Tensile strength | D638 | 52 – 70 MPa | 60 – 84 MPa |

| Tensile modulus | D638 | 2.9 – 3.2 GPa | 3.1 – 3.4 GPa |

| Elongation at break | D638 | 4 – 8% | 3 – 6% |

| Flexural Strength | D790 | 121 – 130 MPa | 134 – 140 MPa |

| Flexural modulus | D790 | 3.1 – 3.3 GPa | 3.3 – 3.5 GPa |

| IZOD Impact (notched) | D256A | 20 J/m | 17 J/m |

| Shore D Hardness | D2240 | 87 | 90 |

| Water sorption | D570-98 | 0.45% | 0.39% |

| Tg | D7028 | n/a | 128°C |

| HDT-B 0.45 MPa | ISO75 | 66°C | 73°C |

| Degradation temperature | Internal method | >250°C[2] | >250°C[2] |

[1]Post-cured 30 minutes with LED curing in the Wicked Engineering Curebox. These values may vary and depend on individual machine processing and post-curing. [2]Short term temperature resistance, discoloration appears at 120°C, no cracking in part up to 250°C / 482°F. Learn about injection molding runs at 200-218°C with PP in these actirles.

| Description | Value |

|---|---|

| Appearance | Opaque grey liquid |

| Viscosity | 550 cps at 25°C |

| Density | 1.12 g/cm3 |

| Ec | 9.88 mJ/cm2 |

| Dp metric | 0.20 mm |

| Dp imperial | 7.87 mils |

More information

Values may vary and depend on individual machine processing and post-curing. For extra details, download the technical data sheet or user guide.

Processing instructions

New to resin 3D-printing, or a seasoned professional, it is advised to scroll through the processing instructions. Detailed information on how to obtain strong resin end products, printing parameters, support settings, cleaning, washing, post-curing, part orientation, shrinkage compensation, minimum wall thickness and other resin characteristics can be found in the link.

| H315: Causes skin irritation. |

| H317: May cause an allergic skin reaction. |

| H319: Causes serious eye irritation. |

| H411: Toxic to aquatic life with long lasting effects. |

3D Printer compatibility

Do you want to use Strong-X? Check if settings are available on our website for your printer!

| Printer name | Compatible? |

| Formlabs Form 2 | Yes |

| Formlabs Form 1+ | Yes |

| DWS Digital Wax 028 | Yes |

| DWS 029X | Yes |

| Carima IM2 | Yes |

| MakeX M-One Pro 70 | Yes |

| W2P SolFlex 150 | Yes |

| W2P SolFlex 163FHD | Yes |

| W2P SolFlex 170 | Yes |

| W2P SolFlex 250UHD | Yes |

| W2P SolFlex 350 | Yes |

| W2P SolFlex 363 | Yes |

| W2P SolFlex 650 | Yes |

| W2P SolLab 370 | Yes |

| Ackuretta Freeshape 120 | Yes |

| Miicraft 125 | Yes |

| Miicraft Ultra | Yes |

| Miicraft Prime | Yes |

| Asiga Max UV | Yes |

| Asiga Max 2 | Yes |

| Asiga Pro 4K | Yes |

| Asiga Ultra | Yes |

| Apex-Maker X1 | Yes |

| Peopoly Moai | Yes |

| Peopoly Phenom Prime | Yes |

| Atum3D DLP Station 5 | Yes |

| Shining3D AccuFab-L4K | Yes |

| Anycubic Photon | Yes |

| Anycubic Photon Mono | Yes |

| Anycubic Photon Mono SE | Yes |

| Anycubic Photon Mono X | Yes |

| Anycubic Photon M3 | Yes |

| Anycubic Photon M3 Plus | Yes |

| Anycubic Photon M3 Max | Yes |

| Anycubic Photon M5s | Yes |

| Anycubic Photon M7 Pro | Yes |

| Anycubic Photon D2 | Yes |

| Creality Halot-One | Yes |

| Creality Halot-Sky 4K | Yes |

| Creality Halot-Sky 6K 2022 | Yes |

| Elegoo Mars | Yes |

| Elegoo Mars 2 | Yes |

| Elegoo Mars 3 | Yes |

| Elegoo Mars 4 | Yes |

| Elegoo Mars 4 Ultra | Yes |

| Elegoo Mars 5 Ultra | Yes |

| Elegoo Saturn | Yes |

| Elegoo Saturn 8K | Yes |

| Elegoo Saturn 3 | Yes |

| Elegoo Saturn 4 Ultra | Yes |

| Elegoo Jupiter | Yes |

| UnionTech Martrix520 | Yes |

| Uniformation GKTwo | Yes |

| Phrozen Shuffle | Yes |

| Phrozen Sonic Mini 4K | Yes |

| Phrozen Sonic Mini 8K S | Yes |

| Phrozen Sonic Mighty 4K | Yes |

| Phrozen Sonic Mighty 8K | Yes |

| Phrozen Sonic Mighty Revo 14K | Yes |

| Phrozen Sonic Mega 8K | Yes |

| Prusa SL1S Speed | Yes |

| Zortrax Inkspire | Yes |

| Zortrax Inkspire 2 | Yes |

| Uniz Slash | Yes |

| Kudo3D Bean | Yes |

| Wanhao D7 | Yes |

| XYZ Nobel 1.0A | Yes |

| Beam3D Prism | Yes |

| Epax3D X1N | Yes |

| Epax3D X10 Color | Yes |

| Epax X10 & E10 Mono | Yes |

| Epax X1K E6 | Yes |

| Flashforge Focus 6K | Yes |

| Flashforge Hunter S | Yes |

| Nexa3D XiP | Yes (open license) |

| Stratasys Origin One | Yes (with OML) |

| Intrepid Automation Epic production system | Yes |

| Intrepid Automation Epic development kit | Yes |

| 385 – 420nm MSLA, SLA & DLP printer | Contact us |

Strong-X use cases

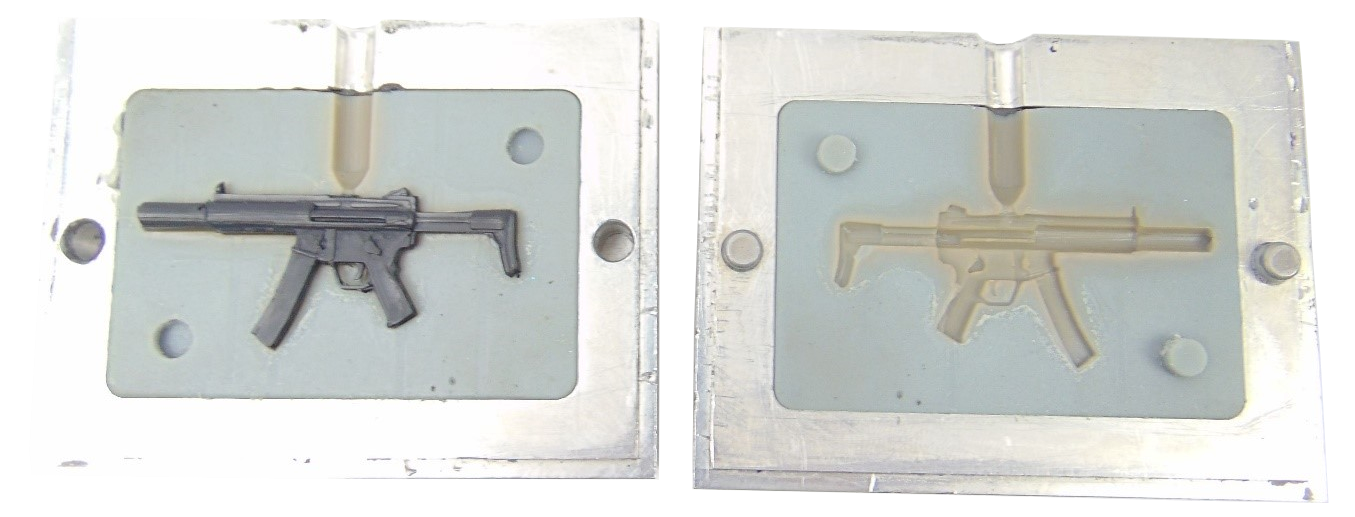

Liqcreate Strong-X is among the strongest photopolymers resins available and perfect for creating injection molding and heavy duty applications.

Jurgen Wiegmann –

Very good for injection moulding! Injection with 280 degrees Celcius gave succes!

George Hinton –

This resin is great for functional engineering models and would highly recommend it.

One tip I have for this resin is that you need thoroughly mix the resin in-between prints

Peter 3D –

Very strong! One of the strongest materials I have seen on the market.