A recent article written by 3D ADEPT Magazine discussed the secrets of resin 3D printing. The original article appeared on 3DAdept.com. This article is slightly altered and shed light on the various features to consider when choosing a resin 3D printing technology. While the choice for a specific technology over another finally comes down to the taste of the person in charge, it should be noted that disadvantages are often highlighted in the use of resin 3D printing, namely the toxicity of the photopolymer resins used. 3D ADEPT Magazine interviewed Liqcreate’s Sales & Marketing Executive, Ruben Soors d’Ancona on this topic.

Ruben Soors d’Ancona, Sales & Marketing Executive at Liqcreate, interviewed about the different forms of toxicity of 3D-printing photopolymer resins.

As companies always strive to do better, we came to realize that some industry insiders currently explore solutions to address the issue of toxicity or 3D-printing resins. One of them is Liqcreate. The Netherlands-based materials’ developer and manufacturer has dedicated its core business to the development of resins. It understands that each 3D-printing application has its own set of requirements which are not often met by ‘off-the-shelf’ photopolymer resins or other materials.

If you are following the 3D printing news, then you probably know that the company recently launched a nano-ceramic reinforced Composite-X resin for 3D-printed heavy-duty parts. In this Opinion of the Week, we caught up with Ruben Soors d’Ancona, Sales and Marketing Executive at Liqcreate to talk about a few non-toxic solutions that can be used in a resin 3D printing process and post-processing.

With a background in International Business and Management, Ruben came to realize the potential of 3D-printing – SLA/DLP 3D printing technology especially – in 2012 at a dental technology company. With a keen eye for digital technologies, the sales expert’s entrepreneurial and creative mind-set has been improved ever since he started working in the resin 3D-printing. As per his words, the technology helps him “see opportunities and build bridges between companies & people.”

Could you tell us more about Liqcreate?

Liqcreate is a company that develops and manufactures quality photopolymer resins for DLP, MSLA/LCD and laser-based 3D-printing technologies. The company was founded in 2017 and delivers its services to a wide range of industries including prototyping, dental, jewelry, industrial, entertainment, consumer goods, healthcare and automotive.

At Liqcreate we also offer solutions to re-brand our product portfolio into any shape. Think about a turn-key solution to simply attach your own label on our products or we can provide our photopolymer 3D-printing resins in bulk volumes.

Next to this we offer the possibility to develop unique and customized photopolymer resins for specific applications. Our chemists and technicians can create resins with different colours and different polymeric properties. Moreover, we can support 3D-printer manufacturers with the development of photopolymers with specific polymerization kinetics to work on any 3D printer. This can help print speed and productivity on any given 3D-printing platform.

As an independent resin developmer and manufacturer with sales, R&D, and manufacturing facilities, we are also able to rapidly scale production where needed. As a result, we can offer large scale 3D printing bureaus and manufacturers the opportunity to quickly get their resin to market in relatively low quantities to minimize their risks.

How can operators recognize a toxic photopolymer resin from a non-toxic resin?

When working with any chemical, including 3D-printing resins, it is important to pay attention to the GHS safety symbols and hazard statements which can be found on the product label and Safety Data Sheet (SDS). These are the main things to pay attention to when evaluating the toxicity of a resin.

To properly understand how toxicity is defined, we have to dive into the hazard statements resins have and evaluate these. There are certain rules and regulations to define the toxicity of a product. These rules and regulations are the CLP Regulations, which are maintained and controlled by the European Chemicals Agency (ECHA). It is the central agency that implements the EU’s chemical legislation to protect people and the environment from the hazards of chemicals.

To simplify this, toxicity can be divided into “toxic for the environment” & “toxic for human beings.” Toxic for human beings is split into acute and long-term effects. If a mixture is not toxic it can still have health hazards, for example, skin irritation, eye irritation, allergic reaction etc.

Engineering 3D-printing resins developed by Liqcreate

Liqcreate started with the development of a non-toxic resin-cleaning agent, why not a non-toxic resin first?

Developing a non-toxic resin with high-end features which is suitable for stereolithography is very complex and perhaps impossible. Creating a resin without hazards is kind of impossible. At the moment, our suppliers for raw materials are not yet able to produce raw materials without any health hazards. Ase these hazards are passed-on to the end-product, we are limited in our options to create a resin.

However, looking at our standard materials we spend a lot of time to keep the amount of hazards to a bare minimum. Furthermore, we are also working on bio-based resins. If you look into the world of chemicals, even the mild cleaning agents used in households everyday have some kind of toxicity and hazard statement on the package. It is almost an utopy to have a resin with zero hazard signs. So the best way is to focus on this is to choose a resin with the least and minimal impact on humans and environment.

In 2018 we participated in a study to formulate a resin with novel renewable (meth)acrylates based on soybean oil for stereolithography 3D printing, together with the University of Groningen, Stenden/NHL University and Green PAC (link to the article)(data study). During this study, we evaluated the possibilities to create a bio-based resin. Results showed that we successfully create a resin with up to 85% bio-based content and quite interesting properties for prototyping applications. The study even won the first price in the SABIC KNCV-MM HBO Poster Award presented by GreenPac during the Dutch Polymer Days (DPD) in 2019. Together with multiple universities, we are now looking further into the market opportunities within recyclable and bio-based materials.

Let’s talk about resin cleaning agents, how to use them?

Ultimately, a resin cleaner aims to clean the part you have 3D-printed with resin before post-curing the part in UV light. The UV post-curing is the final stage of post-processing of resin. Operators are used to choose isopropyl alcohol (IPA) or ethanol as their cleaning solvent. IPA can easily be obtained anywhere and does a very good job dissolving resin 3D-prints. The excess resin will get dissolved in the solvent, which eventually turns from a clear liquid to a coloured and polluted fluid after many prints have passed through. Cleaning with IPA works especially well if IPA concentration is 80% or higher and if it is actively circulated, a feature usually found in resin cleaning equipment.

There are however a couple of potential challenges. IPA is not exactly a safe material, although it is commonly available. It is flammable and cannot be stored without safety precautions. It tends to open up pores of the skin if exposed, and this allows for faster entry of dissolved resin if you’re working with a “dirty” IPA.

For these reasons, we felt there was a need to make post-processing safer and more environmentally friendly. Therefore, we developed Liqcreate Resin Cleaner.

Ruben continues: “Of course, Liqcraete Resin Cleaner is a non-toxic cleaning solution for resin 3D-printed parts. It is a safe, effective solvent that cleans faster than cleaning liquids based on IPA and ethanol. Moreover, it is not a dangerous good, non-flammable and has less odour. Therefore it is excellent for in-office printing. The Resin Cleaner can clean resin 3D-printed parts from these technologies: SLA, DLP and LCD/MSLA, but also build plates and instruments used in resin 3D-printing.”

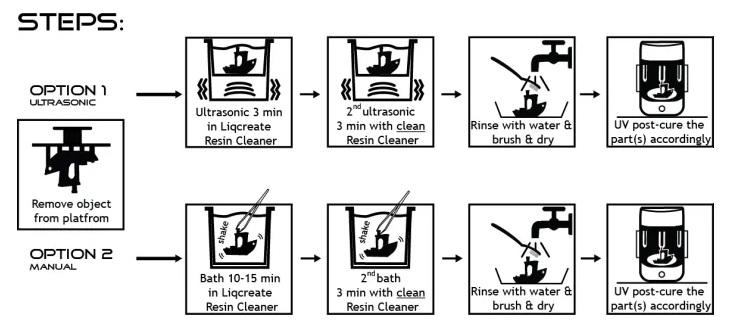

Steps of washing 3D-printing resins in Liqcreate resin cleaner, non toxic eco washing method

Apart from toxicity, are there any differences between non-toxic resin cleaning agents and other resin-cleaning agents?

Apart from toxicity, our Resin Cleaner is more effective compared to IPA and can be used in ultrasonic cleaners. Due to the flammability of IPA, it is not recommended to use this in combination with ultra-sonic cleaners. Using alternative resin cleaners often require a new washing protocol. IPA and Ethanol work great for washing printed parts and are easy to use because the leftover IPA and Ethanol will evaporate. After evaporating, the parts are ready for post-curing. This fast evaporation brings some health side-effects, which are not present in our resin cleaner. The down-side is that the resin cleaner will require a second washing step to remove the excess resin cleaner on the part.

Is there anything else you would like to share on this topic?

Some small tips from our side for using Liqcreate Resin Cleaner to save some money, work more efficiently, and reduce your carbon footprint:

- – When using two separate containers (two-step system) for cleaning your 3D printed objects, you will not only work faster but also reduce your carbon footprint and save money. Using two separate containers will help increase the number of washing cycles which means, you can work longer with the Resin Cleaner.

- – To achieve a perfect surface finish of your part, always wash a second time in a fresh Resin Cleaner.

- – Although our resin cleaner works very well to clean 3D-printed objects, printer build plates and equipment, it should be noted that ABS plastic can crack when in contact with the resin cleaner for an extended time. For instance, handles of your ultrasonic cleaner or other ABS plastic parts.

- – When your Resin Cleaner is very dirty please replace it with fresh Resin Cleaner to ensure your parts will not get a sticky surface.

Liqcreate Resin Cleaner

Liqcreate Resin Cleaner is an excellent, effective non-toxic post-print cleaning solution for 3D printing. It is a safe, highly effective cleans faster than other cleaner liquids based on IPA, bio-ethanol and other chemicals. Liqcreate Resin Cleaner is not a dangerous good, non-flammable and has no unpleasant odor. The cleaning liquid can clean SLA, DLP and LCD printed objects, platforms, instruments and Surfaces (if not made of ABS or polystyrene polymer). It can be used with ultrasonic cleaners and the liquid can be used several times without refilling or filtering the Liqcreate Resin Cleaner. *Not Compatible with Polystyrene and ABS plastic parts (Ultrasonic cleaner handles etc.)

Key benefits |

Resin compatibility |

| · Excellent and effective cleaning | · Liqcreate resin compatible |

| · Minimal odor | · DLP Resin compatible |

| · Non-Toxic, non-hazardous | · SLA resin compatible |

| · Biodegradable | · MSLA / LCD resin compatible |

| · Non-flammable | · More information about this product |

On ma dit quon mettre du charbon dans limprimante pour absorber les odeurs de resine pouvant etre toxique, est ce vrai?

Merci de me conseiller

Thank you for your question. i would not advise to add charcoal in the printer to absorb resin odors. the best way is to choose low odor resins like many liqcreate resins. alternatively use one of these official resin filters that many suppliers offer (we have not tested this as most of our resins are low in odor).

Merci pour votre question. Je ne conseillerais pas d’ajouter du charbon de bois dans l’imprimante pour absorber les odeurs de résine. le meilleur moyen est de choisir des résines à faible odeur comme de nombreuses résines liqcreate. vous pouvez également utiliser l’un de ces filtres à résine officiels proposés par de nombreux fournisseurs (nous ne l’avons pas testé car la plupart de nos résines ont une faible odeur).

Contrairement a ce que dit jimmy, faible odeur ne veut pas dire faible toxicité.

Le meilleur rest les EPI (filtre A1, A2)

Merci pour votre commentaire, c’est tout à fait exact ! Il est donc conseillé de lire au préalable les fiches de données de sécurité, qui indiquent toujours exactement quel équipement de protection individuelle est recommandé.

Thank you for your comment, that is absolutely correct! It is therefore advisable to first read the safety data sheets, which always state exactly which personal protective equipment is recommended.

Una vez polimerizada y post procesada la resina, elastomer x es considerada toxica para humanos?

Dear Cesar,

Gracias por tu pregunta. Para informarle, no hemos realizado ninguna prueba de toxicidad sobre elastómero-x después de la polimerización. Por lo tanto, no podemos decir si es o no es tóxico para los humanos.

Best regards,

Team Liqcreate