The settings or printing parameters for the Anycubic Photon Mono can be changed in the slicer software. There are several slicers available for the Photon Mono resin 3D-printer. Chitubox slicer is one of the mostly used 3D-printing programs for slicing. Most entry and middle-level resin based 3D-printers can be operated through Chitubox. The latest free version of Chitubox has somepowerful tools.

How can I change settings on the Anycubic Photon Mono?

Changing settings and parameters in Chitubox is quite easy when you know the background behind each setting works. In this part we explain how these settings work and how to change the Chitubox settings. First you will have to update your Chitubox to the latest version and add your Anycubic Photon Mono or other 3D-printer. You can add your resin 3D-printer in Chitubox by clicking on “settings”. A new window opens and on the left top side there is an icon with a +. Click on this and choose the brand and model. Most of the printer related settings are correct if you want to print good parts. For extremely high accuracy needs, it can benefit to experiment with settings in the machine or advanced section. Otherwise you can leave them and go the “print” section

How can I change settings on the other Anycubic printers?

Recently Anycubic announced a lot of new printers with quite similar names. it should be noted that some of these printers need different settings or parameters. learn more about the different printers and parameters in this link.

Which settings do I need for Liqcreate resin on the Anycubic Photon Mono?

The engineers at Liqcreate have prepared a setting file which can be downloaded here and imported in chitubox software. By importing the file, you have the right settings for every Liqcreate resin in your chitubox system in a matter of seconds. If you want to make more modifications and learn how the other settings in chitubox work for your Anycubic Photon Mono or similar printer, read the next chapter.

Chitubox settings explained and how to adjust them for Liqcreate resins?

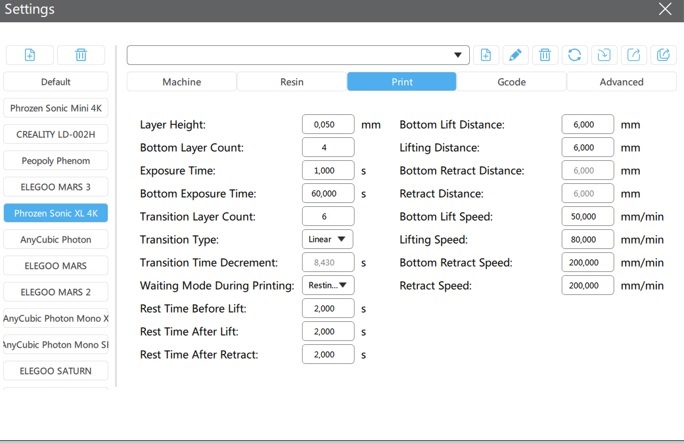

The main settings for Chitubox are listed in the “print” section. Some advanced options like Anti-aliasing, blur and tolerance compensation can be found in the “advanced” section. Most of the time we disable all the advanced options, as these are often still in beta and do not work perfectly. In this article you can find how to read the settings listed and use them in Chitubox.

Settings in Chitubox V1.9. with the rest time and transition layer improvements, also compatible with the Anycubic Photon Mono resin 3D-printer.

Layer height

This is the height of each layer in millimeters. Sometimes settings are given in micrometers / microns / µm. If you have this value in micrometers, then divide it by factor 1000 and your value is in millimeters. The smaller number you fill in here, the thinner the layers. This will give a bit more detail but also increases print time significantly. For most applications 0,1mm is accurate enough. For some detailed dental applications we would advise 0,05mm layer height. Super accurate jewelry applications sometimes require a layer thickness of around 0,025mm.

Bottom layer count

The amount of bottom layers in Chitubox. These layers are exposed for a longer time to get a good adhesion to the build plate. Often a value between 1 and 5 is enough.

Bottom exposure time

Increased exposure time of the bottom / base layers. The bottom layers are often exposed factor 5-20 compared to the regular layers. The better your build plate is calibrated, the lower bottom exposure time you would need. This value is always given in the settings list.

Transition layer count

This new feature in Chitubox helps the regular layers attach to the bottom layers. What happens is that if the difference between bottom layer exposure and regular layer exposure is too big, the regular layers do not attach properly to the bottom layers. To prevent this, you can add a number of transition layers to gradually go from the bottom layers to the regular layers. We often use 1-2 bottom layers and then 6 transition layers.

Transition type

We have not experimented much with this. Linear basically always works for us.

Transition time decrement

This value is automatically calculated by Chitubox. It is basically the interval of seconds that the transition layers change per layer.

Waiting mode during printing

This new setting in Chitubox helps increase surface quality in high demanding applications. Always set it to “resting time” and not to “light off delay”. Light off delay was always a bit vague setting as it waited on top of the lift and the value for most printers should be higher than the combined exposure and moving time. With the option “resting time” you can actually set a time in seconds that it will wait at each step. For flexible resins, dental materials and very demanding applications, a rest time of 2,0 seconds in each step is advised.

Bottom lift distance

This is the distance in millimeters of the bottom layers. For rigid resins 6,0 mm is sufficient. For soft and flexible materials 10 millimeters is advised.

Lifting distance

Distance in millimeters of the regular layers. For rigid resins 6,0 mm is sufficient. For soft and flexible materials 10 millimeters is advised.

Bottom retract distance & retract distance

This setting is automatically calculated and you can not change it in Chitubox. It is the same value as the lift distance.

Bottom lift speed

The bottom lift speed is the speed the build plate moves up in mm / minute for the bottom layers only. For regular materials 50 mm/minute is sufficient. If you happen to have adhesion issues, reducing this value might help.

Lifting speed

The speed in mm/minute the build plate moves up for the regular layers. Usually a lift speed of 90 mm/minute works fine. For rigid resins and parts that do not require high accuracy you can even move up. For soft and flexible resins it is advised to reduce it to maximum 60mm/minute in Chitubox.

Bottom retract speed

The bottom retract speed is the speed the build plate down up in mm / minute for the bottom layers only. For regular materials 100 mm/minute is sufficient. If you happen to have adhesion issues, reducing this value might help.

Retract speed

The speed in mm/minute the build plate moves down for the regular layers. Usually a retract speed of 150 mm/minute works fine. For rigid resins and parts that do not require high accuracy you can even move up. For soft and flexible resins it is advised to reduce it to maximum 60mm/minute in Chitubox.

Help with Chitubox settings for the Anycubic Photon Mono

If you need help with Chitubox settings with Liqcreate general purpose, dental or engineering resins, contact us or send an e-mail to info@liqcreate.com and our technical team will reach out to help.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!