There are plenty of well-known 3D-printing technologies like SLA and SLS. The offering of SLA and SLS printers is exploded the past years with industrial printers, desktop printers and anything in between. For the jetting printers, there has been a limited amount of new entrants and innovations. One of the first 3D-printing companies was Objet. Objet is now part of Stratasys, offering the Objet technology under the PolyJet printer range. Other companies offering jetting 3D-printers are 3Dsystems, Mimaki, Inkbit and DP polar. The latter was acquired by 3DSystems a couple months ago. Learn more in this article what the benefits of this technology are and what type of materials can be processed. A more detailed view of the companies active in this space was published by All3DP.com.

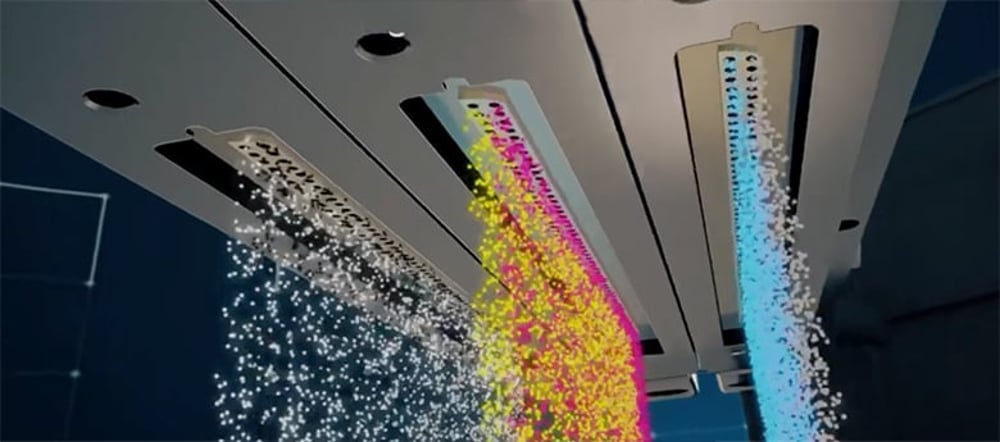

Image by All3DP.com and Stratasys: An illustration of the jetting technology in the Stratasys J55 3D-printer.

How does jetting 3D-printing technology work?

The jetting 3D-printing technology is fairly simple to explain if you compare it to other technologies. Like a 2D-printer, the printer has a print-head containing 100’s of nozzles that deposit a droplet of material on a specific place. With multiple nozzle-arrays, these can also contain different colors or materials with other material properties. After the droplets are placed, an UV light will cure it right away. After a layer is printer, the print-bed will move down and a new layer is deposited on top of this. This way you get from a 2D image to a 3D part.

What are benefits of jetting 3D-printing technology?

With every piece of technology, it has some advantages and disadvantages compared to the other available technologies. In this section we list the advantages of jetting 3D-printing technology.

Color printing: Jetting technology is one of the few 3D-printing technologies that can create full-color objects. If you want to print a model with multiple colors and do not want to post-process it further to create these colors, then Jetting technology can be a very beneficial 3d-printing technology.

Multi material: In a similar way of printing colors, it is also possible to print different types of materials in one design. This is also not possible with most other 3D-printing technologies. Before purchasing a jetting 3D-printer, check if these features are available in the model of interest.

Wax printing: there are some specialized jetting printers that print true wax material. Within the resin space we have developed a wax-based 3D-printing resin and workflow that works well for jewelry, dental and engineering purposes. But it is still different compared to actual wax. With a wax printer you can print this wax and implement it in your casting workflow without much changes to the workflow.

What are drawbacks of jetting 3D-printing technology?

With all these benefits, there are also some drawbacks to this technology.

Surface finish: Often a post-processing is required to get a smooth surface finish, especially on the places where the part is attached to the supports.

Material limitations: When printing with jetting technology, the UV inks have to pass the small nozzles and this requires a very thin / liquid material. This is limiting the mechanical properties or to print a material with reinforced particles like Composite-X. Read below what kind of mechanical properties you can expect from your jetting resins.

Closed systems: All systems that are available at the time of writing are industrial grade systems which are completely closed. So no 3rd party materials can run on these printers and you have to get the materials via the official resellers, limiting your choice of material properties and pricing.

Costs: Often the costs of these jetting printers and materials for jetting are quite steep. It is smart to make a calculation if the benefits are worth the extra costs if you compare it to SLA or DLP 3D-printing. Although you don’t have much options when you want to print multi-color or multi-material resins.

Materials for jetting vs DLP, MSLA & SLA 3D-printing

Jetting resins are slightly different compared to DLP, MSLA or SLA resins. As the viscosity should be much lower, the materials should be stable at jetting temperature and the curing mechanism is often different. Within this comparison we focused on Stratasys and its polyjet materials.

Rigid Jetting 3D-printing resins.

There are plenty of rigid jetting resins available. In the list below you can see a window of properties currently offered and its Liqcreate counterparts for SLA, DLP and MSLA 3D-printing.

Table: Comparing properties of rigid 3D-printed plastic polymers made from Jetting vs. DLP, SLA & MSLA 3D-printing.

| Properties | Rigid & High-Temp: RGD5205-DM | Liqcreate Deep Blue | Liqcreate Clear Impact |

| Tensile modulus | 1,6 – 2,7 GPa | 2,6 GPa | 1,4 GPa |

| Tensile strength | 43 – 55 MPa | 73 MPa | 47 MPa |

| Elongation at break | 5 – 15 % | 5 % | 15 – 25% |

| IZOD Impact strength (notched) | 16 – 19 J/m | 22 J/m | 31 J/m |

| Flexural strength | 50 – 100 MPa | 82 MPa | 58 MPa |

| Flexural modulus | 1,7 – 2,7 GPa | 1,9 GPa | 1,7 GPa |

Tough Jetting 3D-printing resins.

There are some tough jetting resins available. In the list below you can see a window of properties currently offered and its Liqcreate counterparts for SLA, DLP and MSLA 3D-printing.

Table: Comparing properties of tough 3D-printed plastic polymers made from Jetting vs. DLP / SLA & MSLA 3D-printing.

| Properties | Durus: RGD430 | Liqcreate Premium Tough | Liqcreate Clear Impact |

| Tensile modulus | 1,2 – 1,6 GPa | 1 GPa | 1,4 GPa |

| Tensile strength | 30 – 40 MPa | 28 MPa | 47 MPa |

| Elongation at break | 40 – 50 % | 15 – 25 % | 15 – 25% |

| IZOD Impact strength (notched) | 35 – 45 J/m | 43 J/m | 31 J/m |

| Flexural strength | 40 – 50 MPa | 38 MPa | 58 MPa |

| Flexural modulus | 1,3 – 1,7 GPa | 1 GPa | 1,7 GPa |

Rubber-like and Elastic jetting 3D-printing resins.

There are some Rubber-like or tough jetting resins available. In the list below you can see a window of properties currently offered and its Liqcreate counterparts for SLA, DLP and MSLA 3D-printing.

Table: Comparing properties of tough 3D-printed plastic polymers made from Jetting vs. DLP / SLA & MSLA 3D-printing.

| Properties | TangoBlack Plus | Elastico Clear | Liqcreate Flexible-X | Liqcreate Elastomer-X |

| Tensile strength | 2.4 MPa | 2 – 3.5 MPa | 2.4 MPa | 1.5 MPa |

| Elongation at break | 145 – 155 % | 250 – 350 % | 120 – 160 % | 140 – 180% |

| Tear Strength | 5.5 – 6.5 kN/m | 4.5 – 6 kN/m | 14.9 kN/m | 10 – 12 kN/m |

| Shore A Hardness | 35 – 45 | 42 – 50 | 55 | 43 |

Jetting Color 3D-printing examples

Image by All3DP: variety of beautiful color 3D-prints.

When choosing to invest in a new 3D-printing technology, it is always good to calculate the costs and decide if the benefits of the technology outweigh the drawbacks. Additionally, it is important to note if the material properties are good enough for the applications you are printing! If you have any question or comments, reach out to info@liqcreate.com.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!