The liquid density of 3D-printing resins is provided in all technical data sheets. From time to time we received questions regarding the density of solid, 3D-printed parts. In this article you can find the solid density of Liqcreate resins.

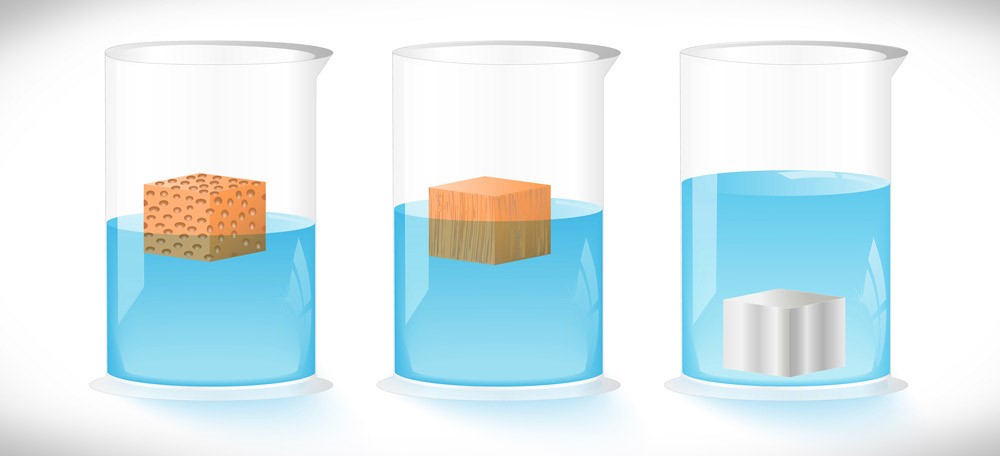

Density and of different objects make them behave different in a liquid, source Anton Paar.

What is the difference between liquid and solid density?

Density of materials can be measured by different methods. An easy method is to fill a flask of 100,00 ml with exactly that amount of liquid resin and then weigh how much of resin was added in grams. For instance, for Strong-X, the filled flask would have 112,0 gram of liquid resin in it, giving it a liquid density of 1,12 g/m3. During curing, the cross-linking process will result in a tighter molecular structure and shrinkage in the material. After post-curing, the density will increase to 1,20 g/cm3 for Strong-X.

Table 1: Solid density after curing of Liqcreate resins:

| Material | Solid density in g/cm3 |

| Strong-X | 1.20 |

| Premium Model | 1.20 |

| Hazard Glow | 1.39 |

| Composite-X | 1.62 |

The density is related to the conversion rate of cross-linking. The best method for this is to use a fully cured part for these measurements. Parts were post-cured according to our post-curing advise.

Why is the solid density of some resins higher?

Most of our resins have a solid density of 1,20 g/cm3. There are two big exceptions, Hazard Glow and Composite-X. The cause of an increased density of both resins has to do with the particles added to both materials. Hazard Glow contains a good amount of glow particles, giving its authentic glow in the dark effect. These particles have a high density, which will increase the overall density of the resin and printed parts. For Composite-X it is even more extreme. Composite-X contains a high amount of ceramic particles, also significantly increasing the liquid and solid density. This link contains more information on density and density measurements, by Anton Paar.

Density of PLA filament compared to 3D-printing resin

PLA Filament (Polylactic Acid) is a biodegradable plastic coming from renewable organic resources like corn starch or sugarcane. PLA Filament can be recycled but can also be biological decomposed in composting plants for some PLA grades. Due to a low shrinkage factor PLA will not deform after cooling, this makes the material ideal for 3D printing. The density of PLA filament is about 1.25 g/cm3. The density of PLA filament is quite similar to un-filled 3D-printing resin density, as for instance Liqcreate Premium Model has a density of 1.20g/cm3.

Team Liqcreate hopes that this article was informative and wish you happy printing. If there are any questions or remarks, feel free to contact us at info@liqcreate.com any time.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!