GENERA was founded in 2015 by Dr. Klaus Stadlmann. They started to develop the GENERA Workflow which was a completely new approach and a unique 3d printing system. The philosophy is to make resin 3D-printing clean, safe & simple. All systems are based on the idea to use a high degree of automation in the workflow to enable real production with 3D printing. The G1/F1 process and the G2/F2 process use a glove-free handling system, is based on an innovative solution involving shuttles. The printed part travels during the production process in a tight box, also known as the shuttle. Both the printed parts and operators hands are protected. The printed parts can be handled and processed without any dripping, contamination or influence of light. The shuttle works as an interface between the 3D printer and the F1 or F2 post-processing units. The entire manufacturing process is documented, which makes it traceable and repeatable. The G3 offers an All-in-One solution, meaning the entire GENERA workflow is handled within the G3 itself. This includes printing the green part, washing and postcuring. All manufacturing data is documented and stored in the GENERA CAM.

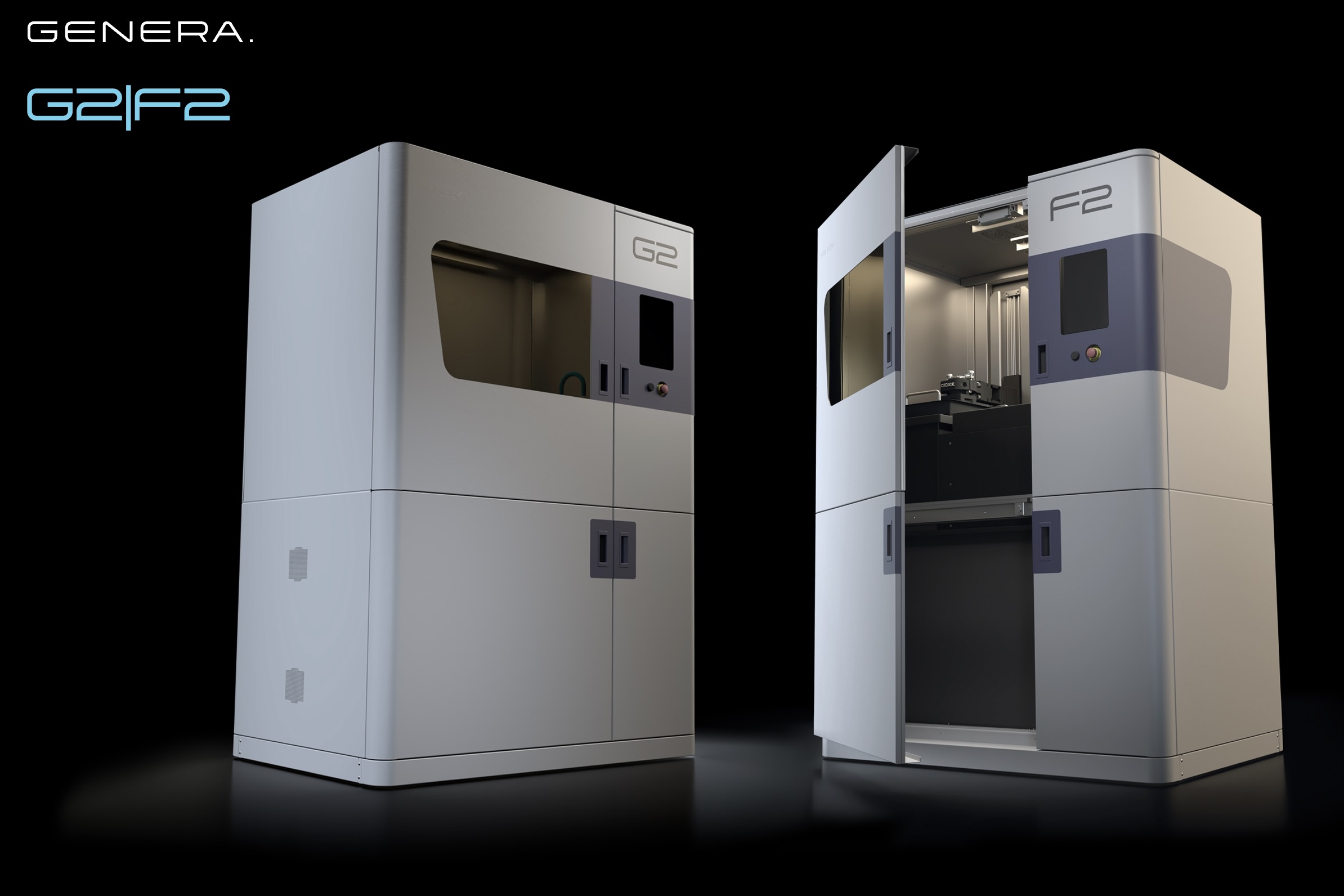

Image by Genera, the F2 and G2 systems for automated resin 3D-printing

Collaboration & compatible Liqcreate resins

Genera and Liqcreate started a collaboration to optimize unique 3D-printing resins on the automated Genera systems. Starting with the G2 and G3 systems from Genera, the following materials are optimized and parameters are available in the Genera software:

More resins to follow in the future.

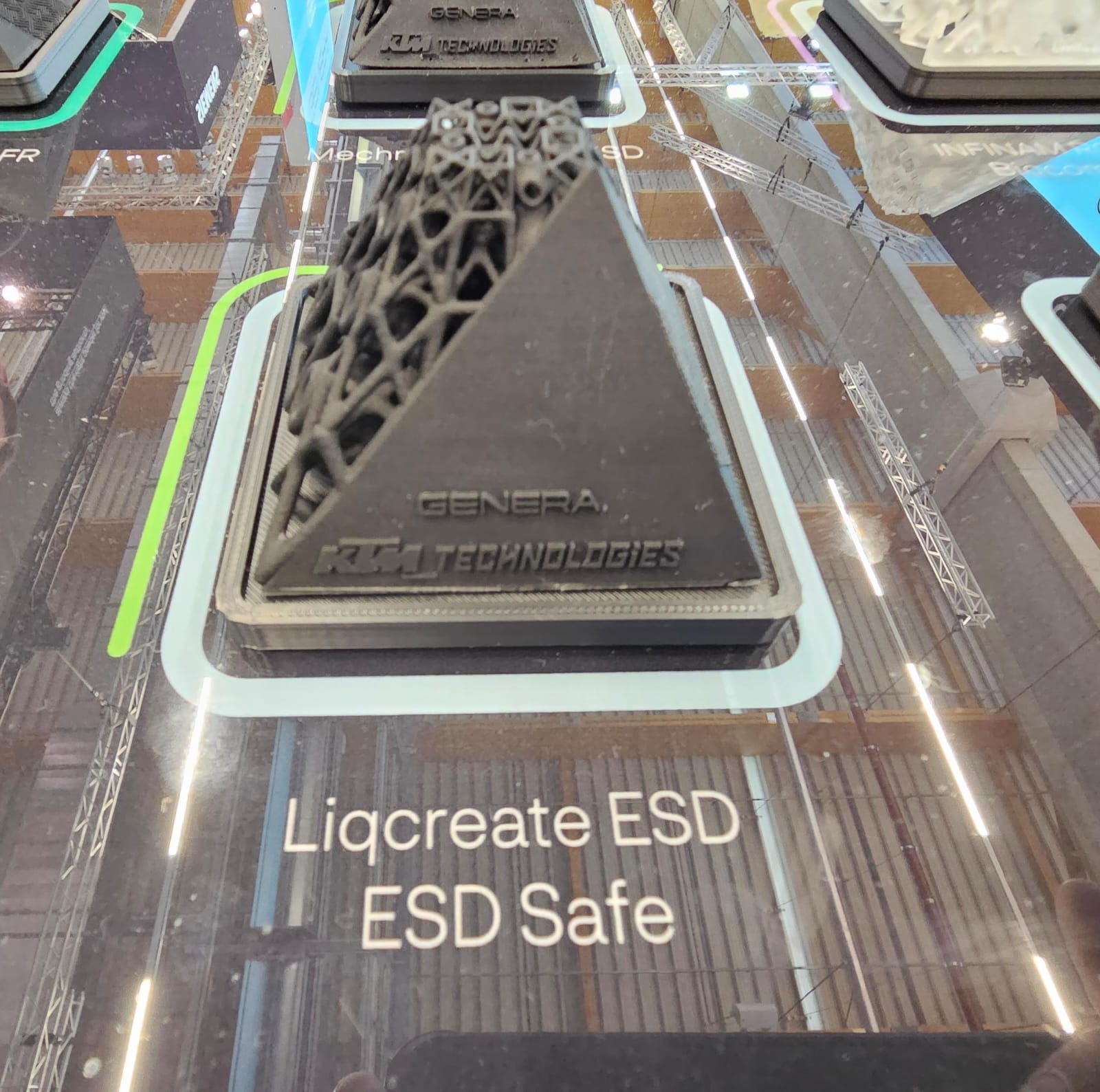

Image from Formnext 2023, showcase of a 3D-printed part from Liqcreate ESD resin on the Genera booth.

Find your Genera compatible 3D-printing resins:

Liqcreate ESD

Liqcreate ESD is an opaque black photopolymer resin and can be processed on most resin based 3D-printers. 3D-printed parts from this material exhibit electrostatic discharge properties needed for electronic manufacturing and parts for ESD-safe workplaces (EPA). Liqcreate ESD can be used on open DLP, LCD and SLA 3D-printers in the range of 385 – 420nm.

Due to the isotropic electrostatic dissipative properties, it is suitable for electronic devices and components that require ESD. Reduce risk and increase manufacturing capabilities by printing custom jigs, fixtures and tools to protect critical electronics components from static discharge.

Key benefits |

3D-Printer compatibility |

| · Isotropic ESD properties | · GENERA G2 & G3 |

| · Well balanced rigidity and impact | · Asiga series |

| · Antistatic properties | · Nexa3D XiP (open license) |

| · Easy to print | · And many more |