Liqcreate Bio-Med Clear is a rigid clear biocompatble photopolymer resin and can be processed on most resin based 3D-printers. 3D-printed parts from this material exhibit biocompatible properties when post processed according to the processing instructions1. After washing and post-curing according to the instructions, printed parts from Liqcreate Bio-Med Clear pass the biocompatibility tests of:

| ○ Cytotoxicity | ISO 10993-5:2009 |

| ○ Sensitization | ISO 10993-10:2021 |

| ○ Irritation | ISO 10993-23:2021 |

Printed parts from Bio-Med Clear can be disinfected with commonly used disinfectants and sterilized by steam sterilization using an autoclave. In this article you can find tips and tricks to work with Liqcreate Bio-Med Clear – biocompatible 3D-printing resin. Find printer settings, washing and curing protocol to get biocompatible parts and more detailed information about sterilization. If you have any questions, reach out to us at info@liqcreate.com and our technical team will assist.

The following topics are covered in this article:

- Shake before use.

- 3D-printing parameters.

- Support settings.

- Cleaning, washing and post-curing to get biocompatible resin parts

- Biocompatibility – biocompatible resin

- Steam sterilization protocol

- How to clean the resin by filtering

- Minimum wall thickness.

- Part orientation and over-hang.

- Part surface finish.

- Shrinkage compensation.

- Resin temperature.

- Solving print failures.

- Storage conditions.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Technical →

1) Shake before use.

Before printing make sure to shake the bottle for 2 minutes and then wait for 10 minutes to let the air bubbles escape. Additionally it is advised that the temperature of the resin and print environment are between 20-25°C (68°F / 77°F)

2) 3D-printing parameters.

Liqcreate Bio-Med Clear 3D-printing resin is designed for open compatibility on 405nm and 385nm DLP, MSLA, LCD and laser-based resin 3D-printers. It is important that the 3D-printer is open for 3rd party resins and parameters can be changed. A lot of parameters are already prepared and listed here. Click on your actual printer to see if Liqcreate Bio-Med Clear parameters are available. If that is not the case, send an e-mail to our technical team at info@liqcreate.com and they will try to help.

3) Support settings.

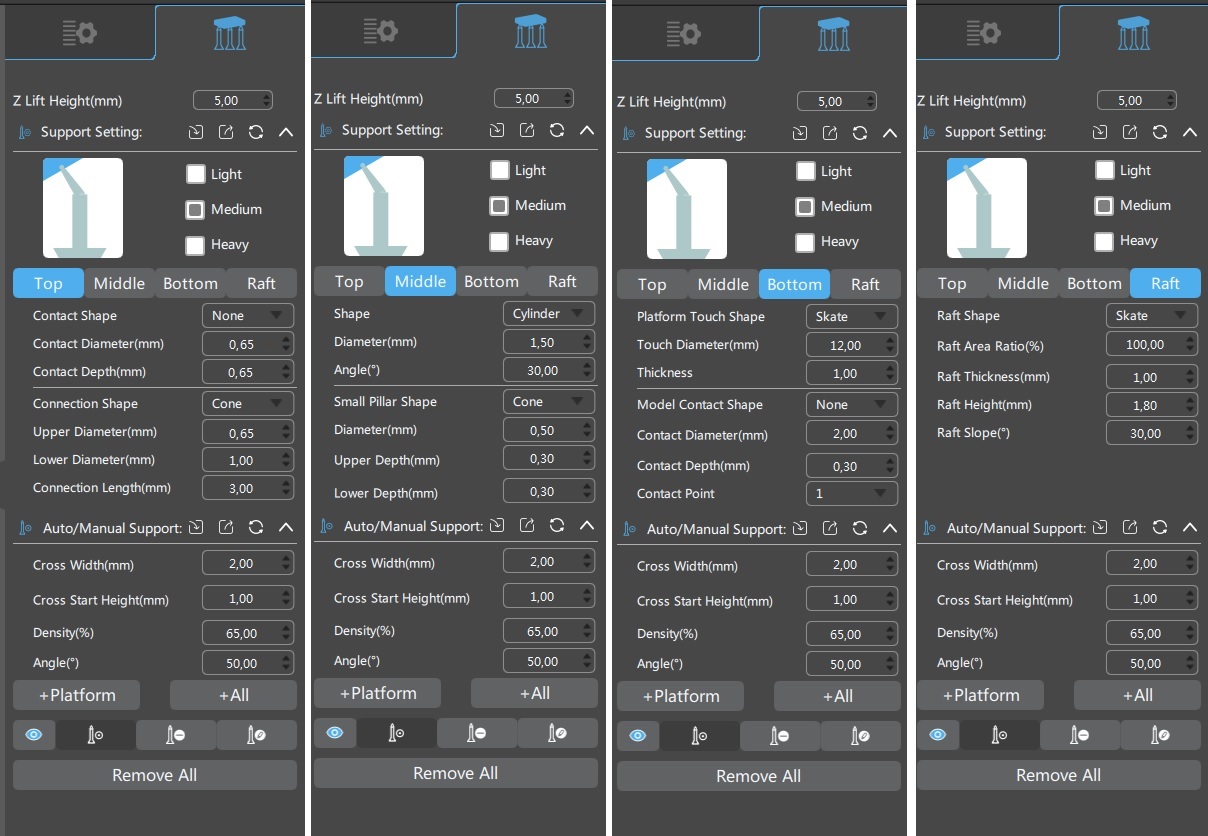

Support settings are depending on the type of resin in combination with the type of printer, release mechanism, material on the bottom of the resin tank and also the secondary settings like print speed. With the extreme growth of available resin 3D-printers in the past years, it is impossible to give validated support settings for each printer. In this section you can find settings for some generic printers, design and print speed.

Image: generic support settings used to succesfully print the test-files with Liqcreate Bio-Med Clear – Biocompatible 3D-printing resin.

4) Cleaning, washing and post-curing to get biocompatible resin parts

For reaching the properties as described above and to insure biocompatibility it is important to follow the validated workflow described. Before printing make sure to shake the bottle for 2 minutes and that the parts are printed in an environment at 20-25°C. Validated printer settings can be found on this link.

Wash and cure process

1. Remove the parts from the build platform.

2. Remove the support structures.

3. Wash the parts for 2 minutes in IPA or ethanol in an ultrasonic cleaner.

4. Wash the parts for a second time for 2 minutes in fresh IPA/Ethanol.

5. leave the parts to dry under ambient conditions for a minimum of 60 minutes.

6. Cure the parts for 30 minutes at 60°C in the Wicked Engineering Curebox.

5) Biocompatibility – biocompatible resin

Liqcreate Bio-Med Clear has been proven capable of passing the cytotoxicity testing according to ISO 10993-5:2009, sensitization testing according to ISO 10993-10:2021 and irritation testing according to ISO 10993-23:2021 within a specific workflow and post-curing. When using this product for making a regulated medical device the user must assume all the responsibility for registration and use of this device.

6) Steam sterilization protocol

Printed parts from Bio-Med Clear can be disinfected with commonly used disinfectants and sterilized by steam sterilization using an autoclave. Standard steam sterilization programs have been validated at 121°C / 250 °F and at 134°C / 273°F for this biocompatible resin. For biocompatibility and also steam sterilization (autoclave) compatibility it is important that the parts are post-cured properly according to the instructions above.

7) How to clean the resin by filtering.

Liqcreate Bio-Med Clear can be filtered similar to other resins. Make sure that all the filters and parts that come in contact with the resin are clean and free from contamination to ensure biocompatibility of the end-part.

8) Minimum wall thickness.

The advised average minimal wall thickness for Liqcreate Bio-Med Clear is 2mm. it is possible to print finer details in local areas. Also larger thin walls can be printed but will require extra support structures for succesful printing.

9) Part orientation and over-hang.

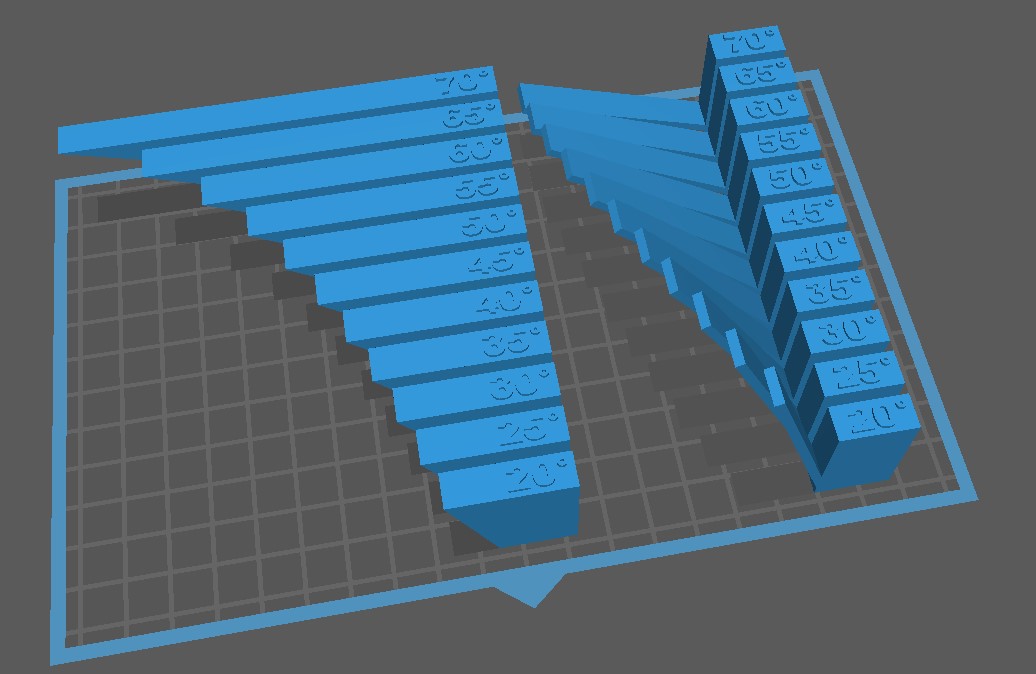

It is not advised to print large and relatively flat parts on supports due to loss of resolution on the support side of the part. If possible, print at an angle to prevent large bottom surfaces as the quality when printing in an angle is much better. In this test was printed with a part from Thingiverse. The thingiverse file was rather solid, while the modified part has a wall thickness of 2.0 mm.

Image: Testing printing angle with the Thingiverse (Thing 40382) file and a small modification of it with thinner walls (2.0 mm).

Even though it is easy to print large overhangs with Liqcreate Bio-Med Clear, It is advised to support parts from 50° to get a good success rate during printing.

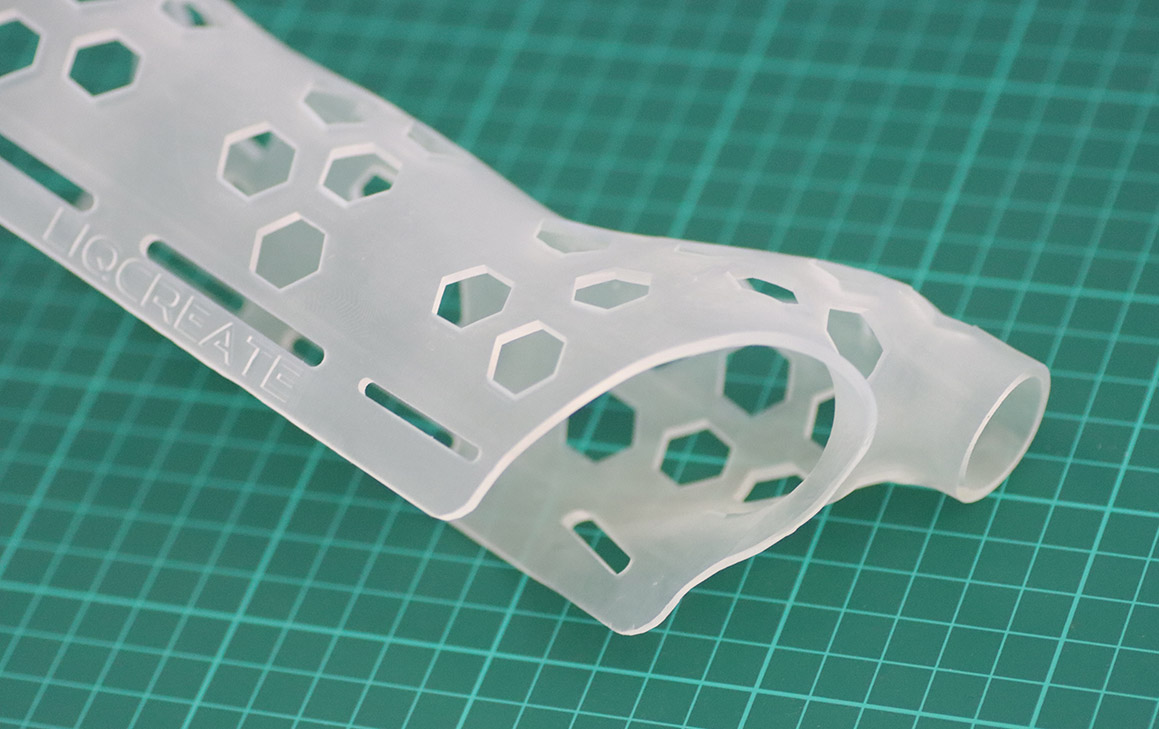

10) Part surface finish.

Printed parts from Liqcreate Bio-Med Clear are transparent during printing. A matte / dull surface will appear after washing and drying as in the picture below. Parts can be polished or coated to get a clear surface finish. Over-curing parts can also lead to better transparency. This will also affect print dimensions and is therefor not advised.

Image: 3D-printed part with Liqcreate Bio-Med Clear – biocompatible 3D-printing resin.

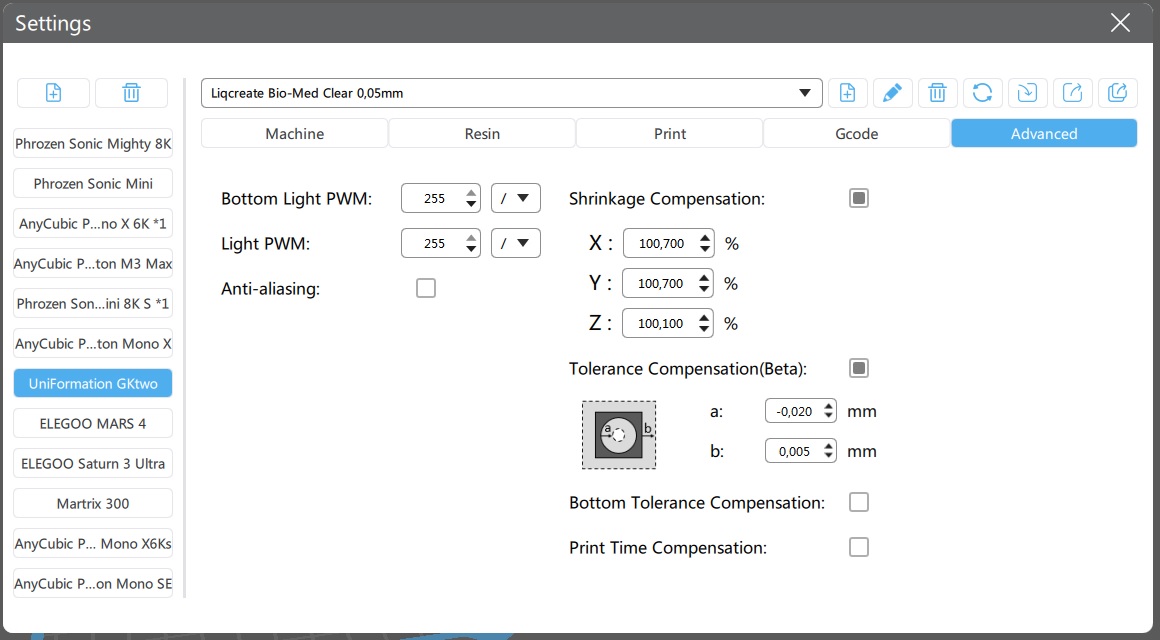

11) Shrinkage compensation.

Tested on the Uniformation GKTwo, the shrinkage compensation in Chitubox to get better accuracy can be found in the picture below. If you need super accurate parts, it is worth to read this article. Shrinkage and off-set parameters for a range of resin 3D-printers are tested and published in the link.

Image: Shrinkage / tolerance compensation for Chitubox tested on the Uniformation GKTwo.

12) Resin temperature.

It is advised to print with Liqcreate Bio-Med Clear – biocompatible 3D-printing resin at least at 20°C / 68°F and maximum at 25°C / 77°F. printing at lower temperature causes random failure in the material.

13) Solving print failures with Liqcreate Bio-Med Clear resin.

There are a lot of common resin 3D-printing issues. In this article you can find 10 common resin 3D-printing fails and how to solve them. If you have need support, send is an e-mail at info@liqcreate.com and our technical team will try to assist.

14) Storage conditions.

Store the product in its original bottle, plug and cap at minimal 5°C / 41°F and maximum 30°C / 86°F. Avoid sources of heat, radiation, static electricity, sunlight and contact with food.

If you have any questions when working with Liqcreate Bio-Med Clear – biocompatible 3D-printing resin, send us an e-mail at info@liqcreate.com.

About Liqcreate Bio-Med Clear

Liqcreate Bio-Med Clear is a rigid clear biocompatble photopolymer resin and can be processed on most resin based 3D-printers. 3D-printed parts from this material exhibit biocompatible properties when post processed according to the processing instructions1. After washing and post-curing according to the instructions, printed parts from Liqcreate Bio-Med Clear pass the biocompatibility tests of:

| ○ Cytotoxicity | ISO 10993-5:2009 |

| ○ Sensitization | ISO 10993-10:2021 |

| ○ Irritation | ISO 10993-23:2021 |

Printed parts from Bio-Med Clear can be disinfected with commonly used disinfectants and sterilized by steam sterilization using an autoclave.

Key benefits |

3D-Printer compatibility |

| · Biocompatible | · Asiga UV series |

| · Steam sterilization possible | · Elegoo & Anycubic series |

| · High accuracy | · Phrozen series |

| · Dimensional stable | · And many more |