Liqcreate ESD is an opaque black photopolymer resin and can be processed on most resin based 3D-printers. 3D-printed parts from this material exhibit electrostatic discharge properties needed for electronic manufacturing and parts for ESD-safe work places. Liqcreate ESD can be used on open DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. Reduce risk and increase manufacturing capabilities by printing custom jigs, fixtures and tools with Liqcreate ESD to protect critical electronics components from static discharge. Liqcreate ESD is a cost-effective solution for producing static-dissipative parts designed to endure on the factory floor. In this article you can find tips and tricks to work with Liqcreate ESD 3D-printing resin. Also there might be some odd structures mainly on build plates which are normal, which we explain in this article. If you have any questions, reach out to us at info@liqcreate.com and our technical team will assist.

The following topics are covered in this article:

- Shake gently before use. (do not use an automatic tumbler / mixer)

- 3D-printing parameters.

- Support settings.

- Cleaning, washing and post-curing your part.

- How to clean the resin? (Do not filter the resin)

- Minimum wall thickness.

- Part orientation and over-hang.

- Resin patterns on build plate.

- “Oily layer” on top of resin.

- Part surface finish.

- Shrinkage compensation.

- Resin temperature.

- Solving print failures.

- Storage conditions.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Technical →

1) Shake gently before use. (do not use an automatic tumbler / mixer)

For most resin, shaking for a couple minutes is advised, especially after longer storage to get a homogeneous mixture before printing. With Liqcreate ESD resin, the material does not need extended or continues shaking. It will have the negative effect of extra air in your resin which is a bit harder to get out again, compared to regular resins. Therefor a gentle shake is enough and machine mixing / automatic tumblers are not recommended. Did you accidentally shake too long or use an automatic tumbler? Let the resin sit for a while before using it to make sure your parts are not porous.

2) 3D-printing parameters.

Liqcreate ESD 3D-printing resin is designed for open compatibility on 405nm and 385nm DLP, MSLA, LCD and laser-based resin 3D-printers. It is important that the 3D-printer is open for 3rd party resins and parameters can be changed. A lot of parameters are already prepared and listed here. Click on your actual printer to see if Liqcreate ESD parameters are available. If that is not the case, send an e-mail to our technical team at info@liqcreate.com and they will try to help.

3) Support settings.

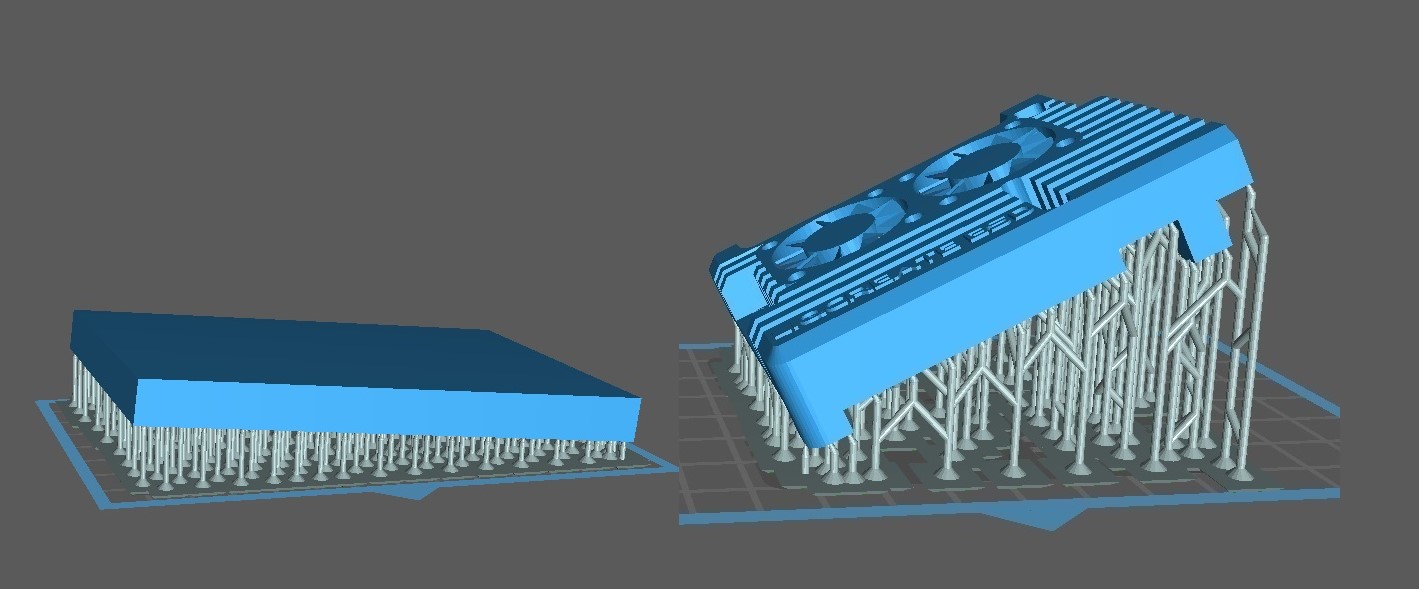

Support settings are depending on the type of resin in combination with the type of printer, release mechanism, material on the bottom of the resin tank and also the secondary settings like print speed. With the extreme growth of available resin 3D-printers in the past years, it is impossible to give validated support settings for each printer. In this section you can find settings for some generic printers, design and print speed. Two test files were printed, one generic file in a 30 degree angle and one dense block in a 5 degree angle.

Image: Test parts to optimize support settings.

Support settings on the Anycubic Photon D2 with Liqcreate ESD resin were successful for the dense part as the regular part on both the fast as regular speed settings. These support settings are listed below. It should be noted if you print an even more dense part. For instance the same box without the 5 degree angle, it requires thicker supports to get a successful print. Additionally, if possible the orientation of the box should be changed as the bottom surface will not have the best quality. In chapter 7 we explain how to orient and to minimize large bottom surfaces.

Image: Support settings from Chitubox of Liqcreate ESD resin that work well with the Anycubic Photon D2 printer with our test geometries.

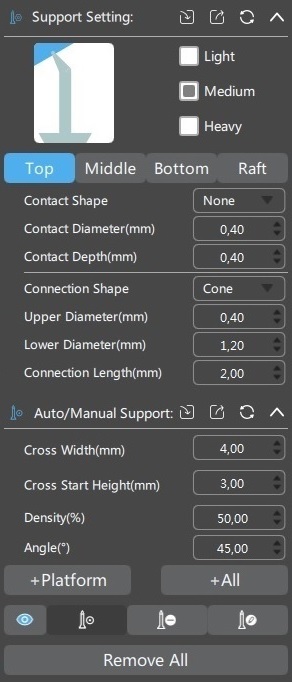

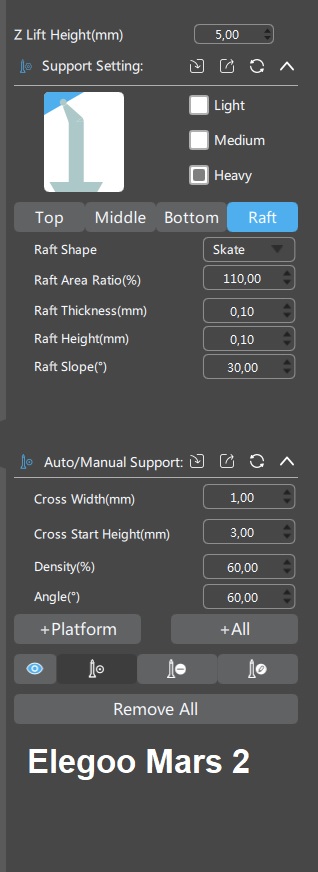

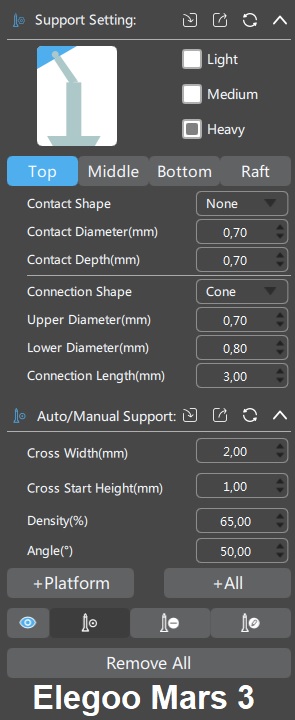

Support settings for the Elegoo Mars 3 and Elegoo Mars 2 were different and can be found below. The Mars 3 needs thicker supports while the Mars 2 needs a different support raft design to get good adhesion to the build plate. For other LCD based printers the settings for the Mars 3 are a good starting point.

4) Cleaning, washing and post-curing your part.

Washing is similar to other Liqcreate resins. wash in either IPA, Ethanol or Liqcreate resin cleaner. For resin cleaner the cleaning instructions on that webpage can be used. For IPA and Ethanol they can be used in an ultrasonic cleaner or cleaner with agitation (like the new low costs Anycubic / Elegoo washing unit). Preferably 2 times 2 minutes washing and the second time in fresh IPA / ethanol. If there are small cavities that are not cleaned by this method, then use a soft brush to clean them out and wash in fresh solvent again for 1 minute. Then let the part dry. Before post-curing, inspect that the part is dry and completely free from solvent (no shiny resin spots on the surface). Otherwise wash again in fresh solvent for 1 minute. Do not wash for longer than necessary as parts can deform when exposed to IPA / Ethanol for >60 minutes when not fully cured. Also be careful if your parts are thin (<2mm) and the IPA in the ultrasonic cleaner is warm (>25°C), parts can warp. If you notice this, either make the parts thicker or wait until the temperature of the IPA is below 25°C.

When small holes and areas are difficult to clean due to the resin viscosity, then brushing with a soft brush is advised to clean the specific areas. After brushing, rinse in fresh IPA / ethanol to get all resin leftovers cleaned.

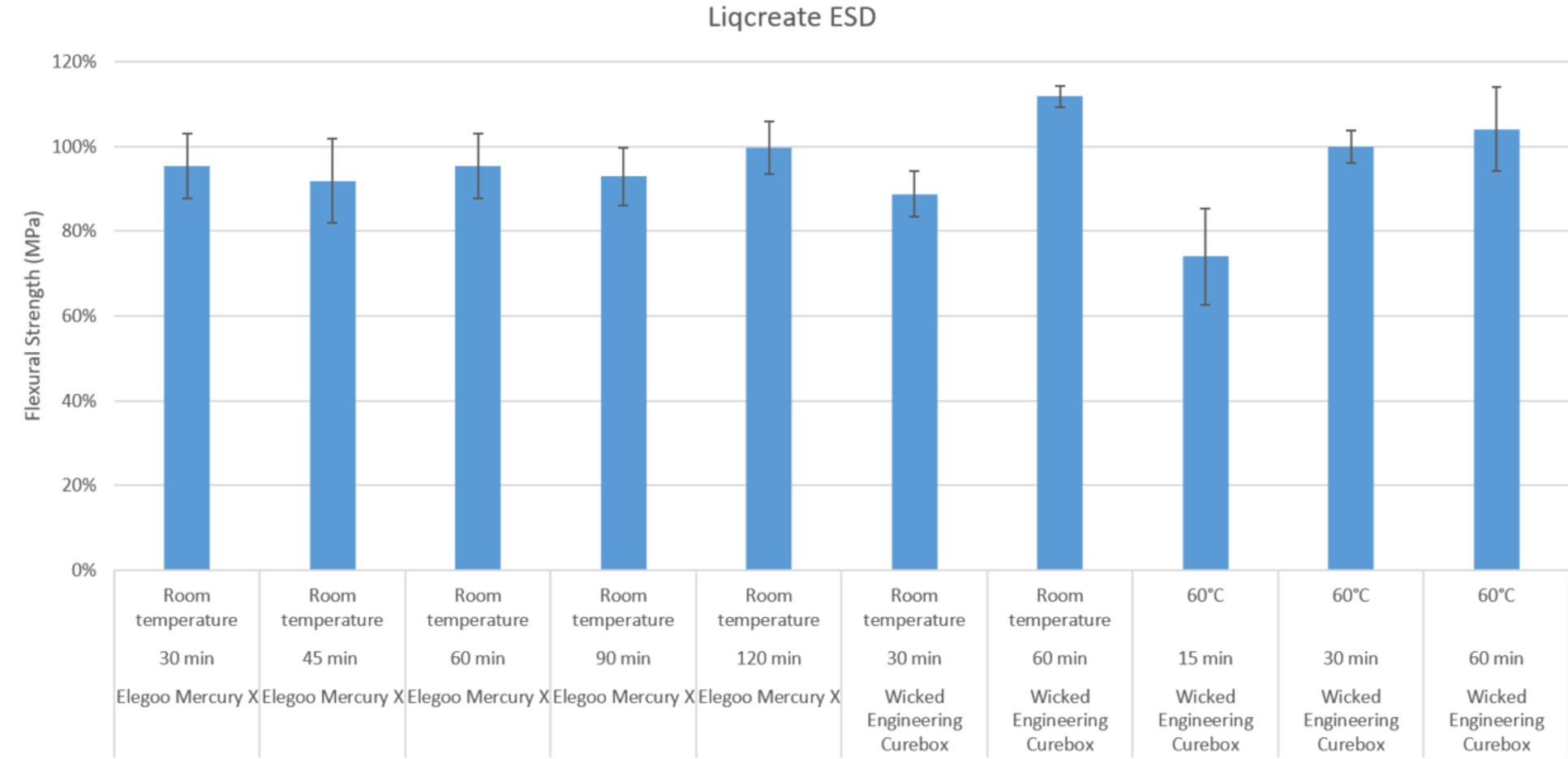

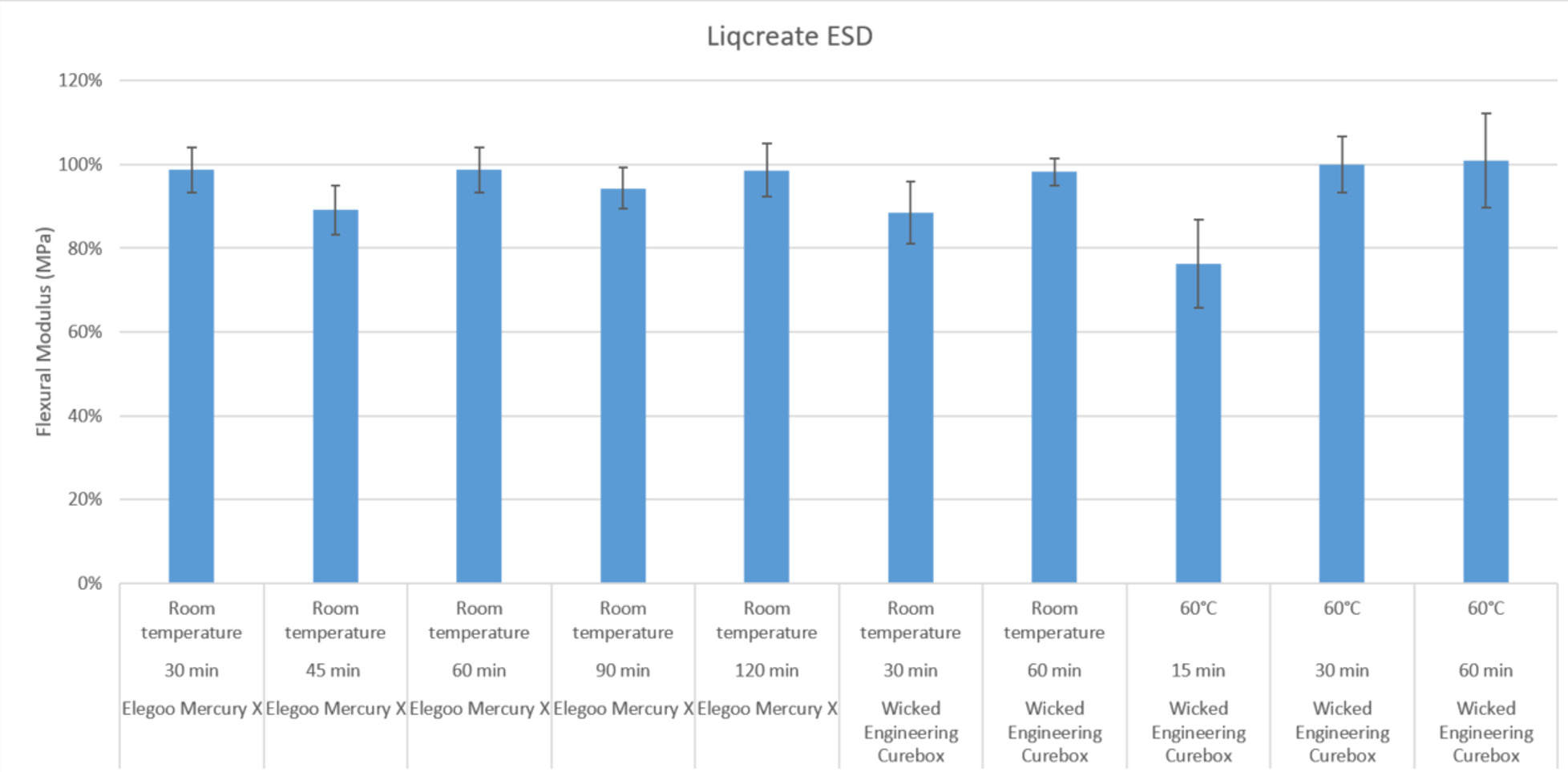

If you have a heated curing unit, then cure for 30 minutes at 60°C to achieve optimal properties, otherwise 30 minutes at room temperature is sufficient. Extended post-curing information and testing of different curing units can be found in this link. Mechanical properties cured in the Wicked engineering Curebox and the Elegoo Mercury X can be found below. Reference with wicked engineering curebox 30 minutes at 60°C is set at 100%.

5) How to clean the resin? (do not filter the resin).

When a part is not completely printed, it is always advised to clean your resin tank. This is usually done by filtering the resin to make sure all rigid plastic pieces are gone. If cured resin parts are present when you start a new print, they can damage your FEP film of even your LCD screen. With Liqcreate ESD resin it is impossible to filter the resin as the filter gets clogged in a few seconds. There are a couple ways to clean the resin:

A) Use a course mesh sieve. A metal sieve has a bigger mesh compared to a resin filter. This works well to filter Liqcreate ESD resin and the filter will not clog.

b) Use the cleaning tool in the 3D-printer. A lot of printers have a cleaning tool to expose the bottom layer for a few seconds to get it cured. Peel off the cured film (with all contaminations cured in it) and throw it away.

c) If stuck to the bottom. If parts are only stuck to the bottom and not floating around, then you can gently collect the resin in a clean container and leave the plastic parts to the bottom of the FEP until you are done collecting the resin. After that, clean the resin tank by removing the plastic pieces. Do this gently to not deform or damage the FEP film.

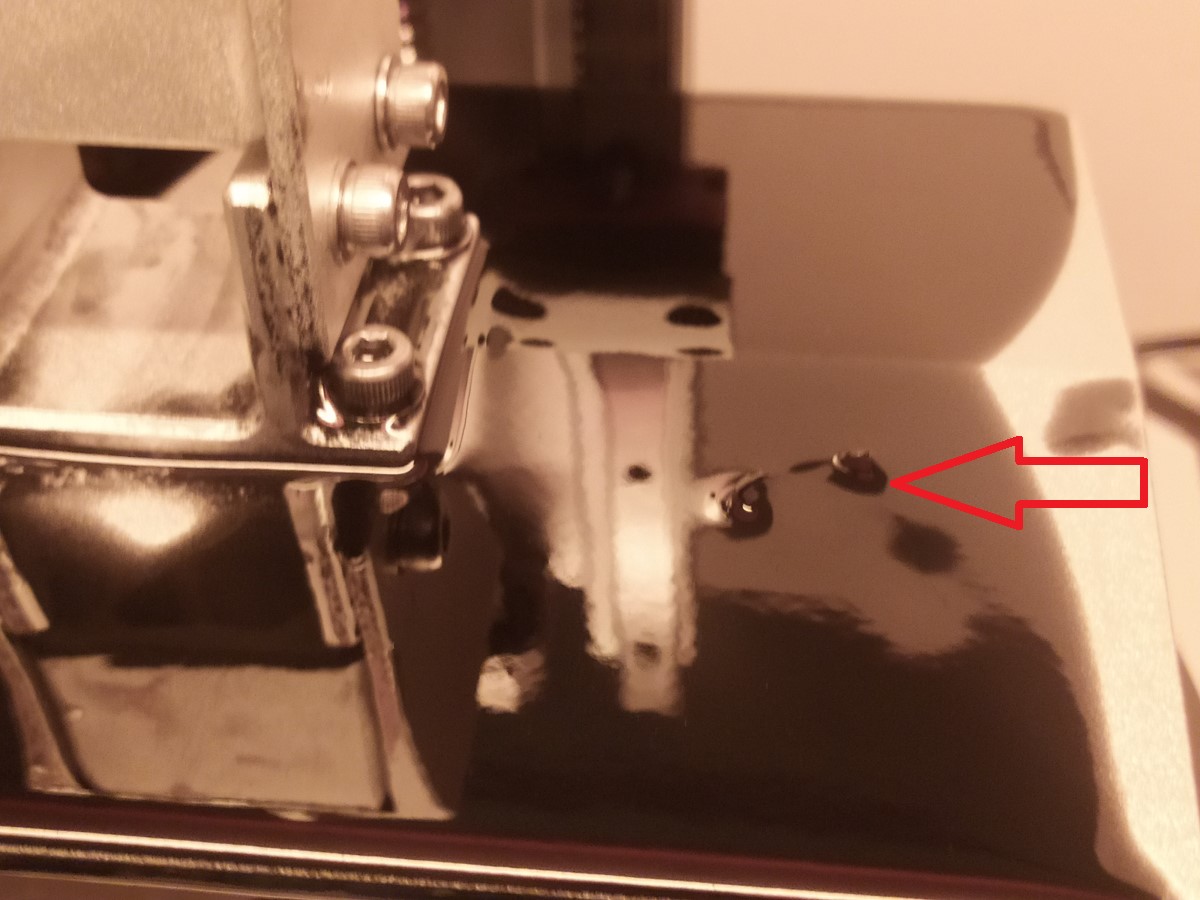

d) When pieces are floating around. When pieces are floating around it gets a bit more difficult. The best method is to wait a day and use method a. alternatively, you can collect all the resin in a clean container and pour it slowly on the build plate. When a piece of solid plastic comes out it will disturb the flow and will – in most cases – be visible on the platform. Do this slowly and pick the rigid plastic pieces out when you see one. This is the least favorite method as you can miss pieces when they are extremely small, when your focus is gone for a moment or when you are pouring too fast.

Image of Method d: a plastic piece of a few millimeters is visible on the platform.

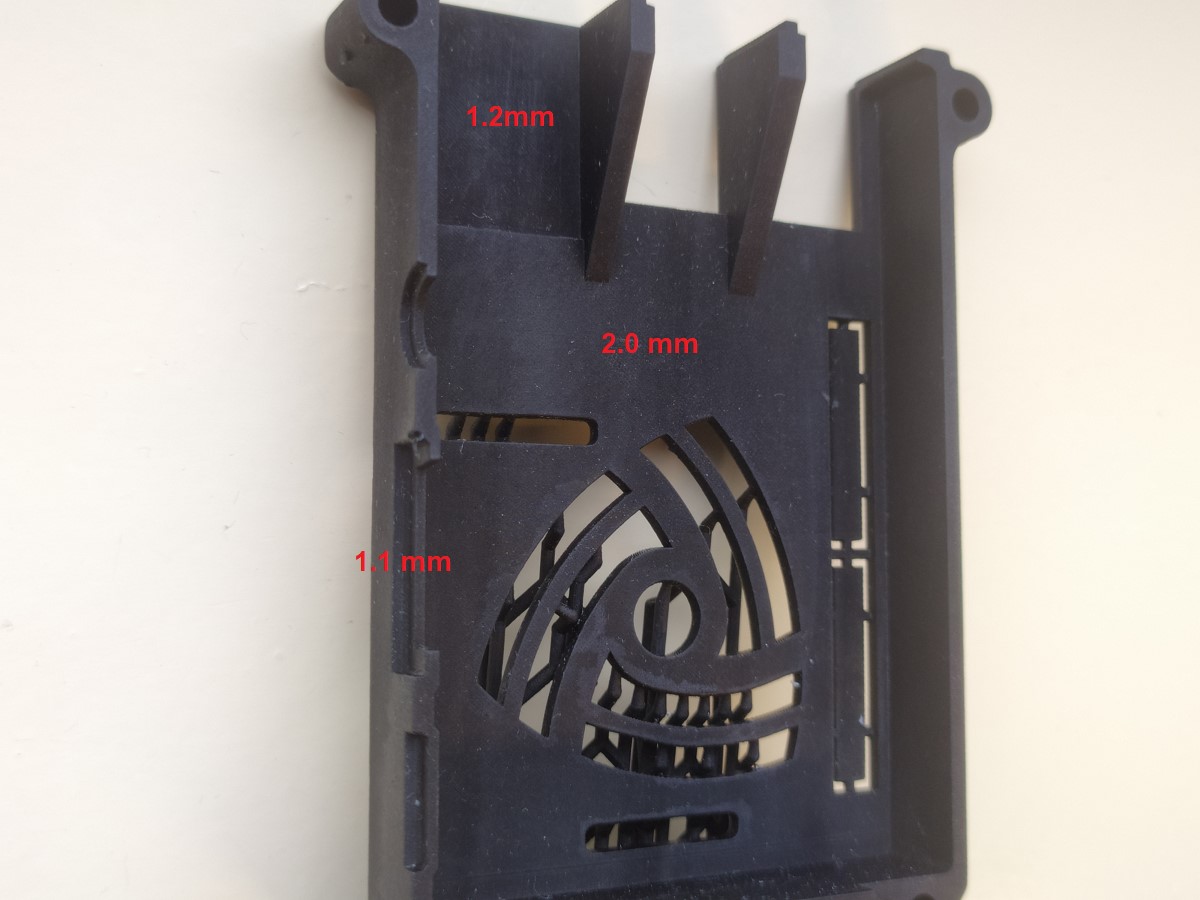

6) Minimum wall thickness.

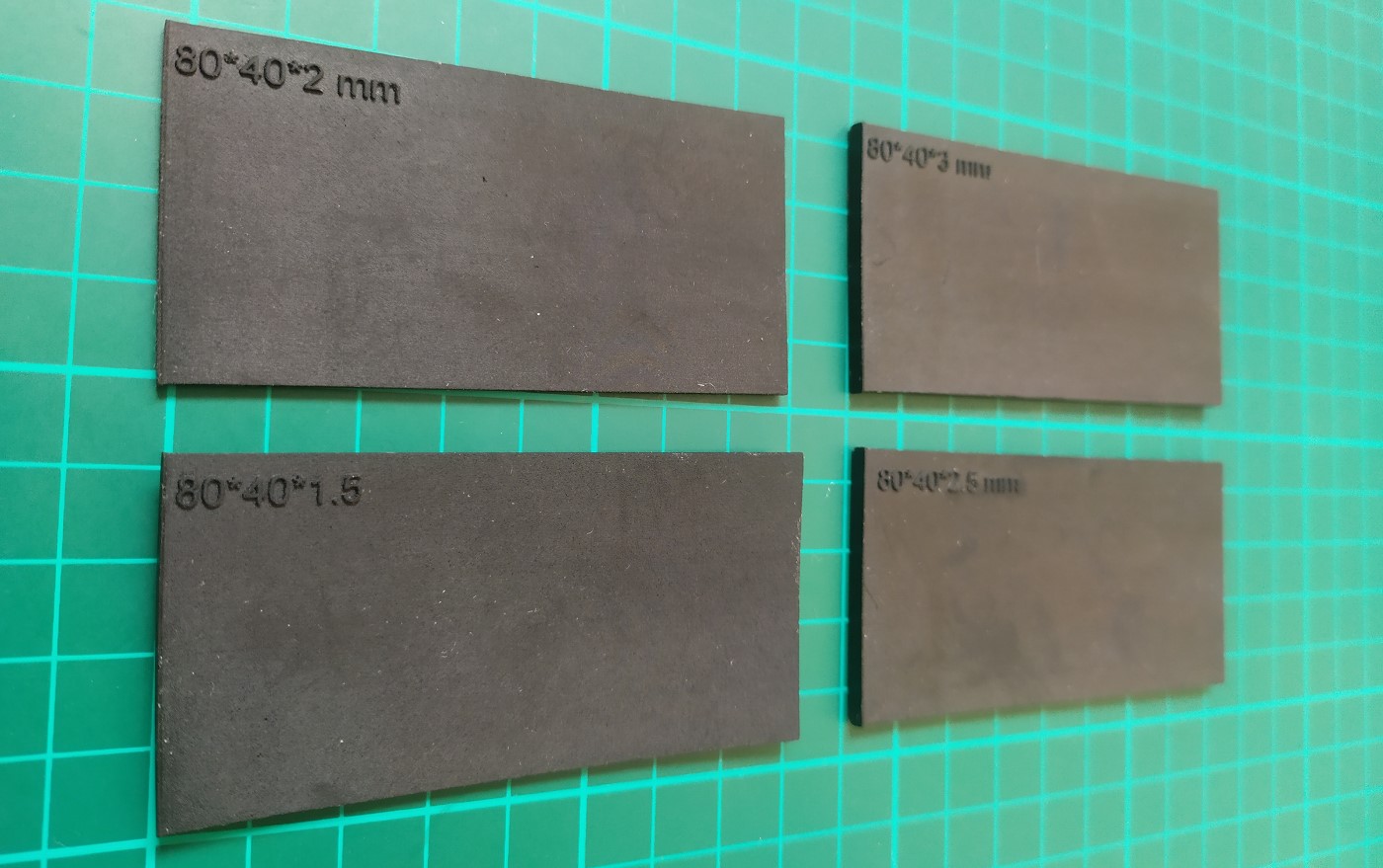

It is possible to print fine details with Liqcreate ESD 3D-printing resin. However, large thin areas can warp during post-processing. It is therefore advised to maintain a minimum wall thickness for these large areas. When testing the minimum wall thickness over an area of 80 * 40 mm, below a wall thickness of 2mm warpage can occur post-curing.

Image: Warping of ESD resin with parts below 2mm wall thickness.

If printing larger areas then 80 * 40 mm, even bigger wall thickness is advised. Please note that smaller details like the text on top of the parts in the image above are possible to print and also finer features, as long as the overall part is not too thin to prevent warping.

Image: Raspberry Pi casing from thingiverse (thing 922740) to show that smaller features and locally lower wall thickness is possible.

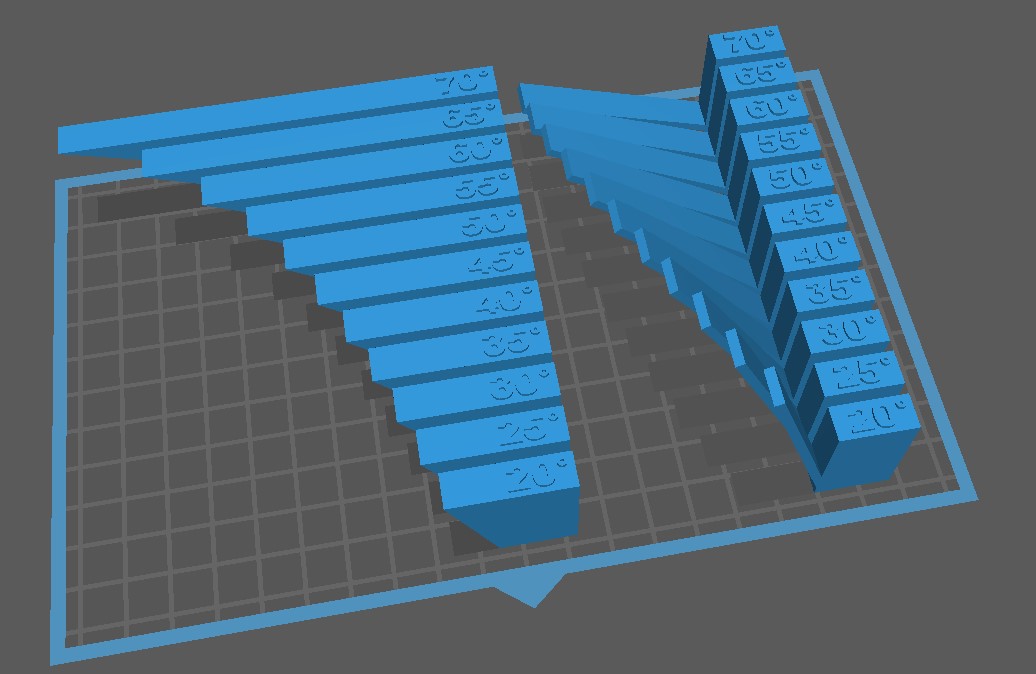

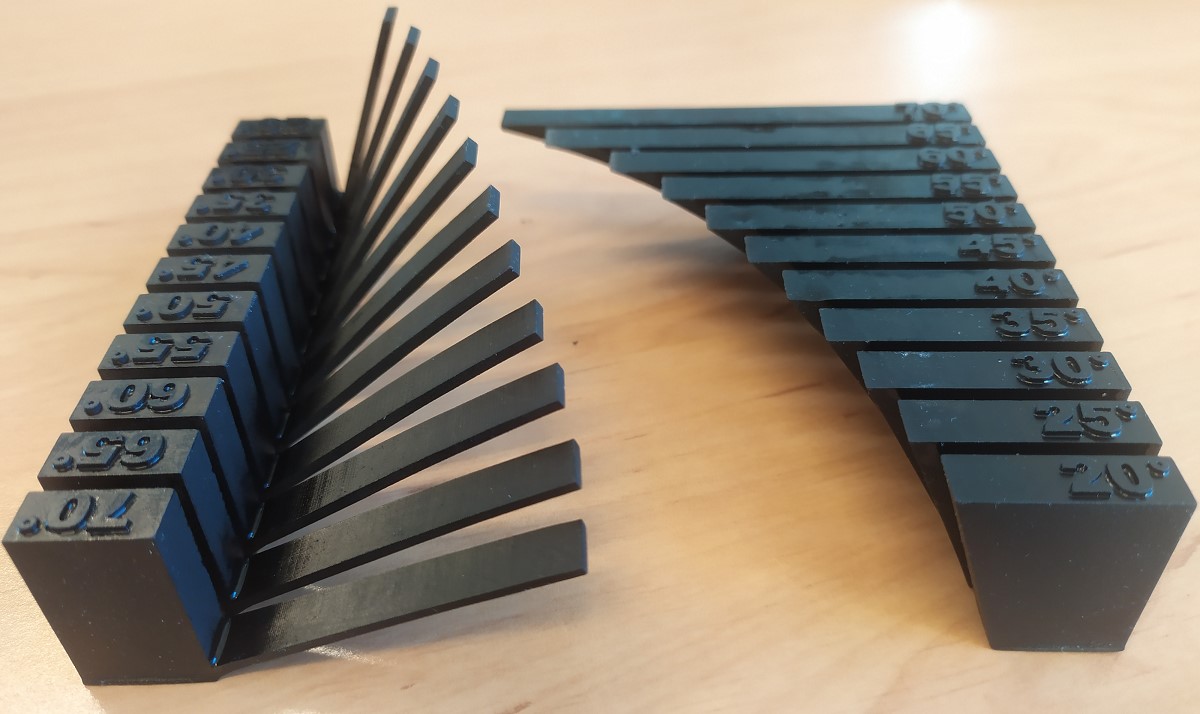

7) Part orientation and over-hang.

The adhesion layer of the part to the build plate of Liqcreate ESD can exhibit lower ESD properties. It is therefore recommended to always print your part on support to achieve homogeneous and isotropic ESD properties. If possible, always print at an angle to prevent large bottom surfaces as the quality when printing in an angle is much better. In this test we printed a part from Thingiverse and also made a modification on it to see at which angle the parts can be printed. The thingiverse file was rather solid, while our own modification had a wall thickness of 2.0 mm.

Image: Testing printing angle with the Thingiverse (Thing 40382) file and a small modification of it with thinner walls (2.0 mm).

Surprisingly all parts printed well, even with an angle of 70°. But what you see is that the 2mm thick part starts to deform at an angle above 45° and the dense part at an angle above 55°. It is advised to support parts from 40°.

Image: test to print at different angle without supports with Liqcreate ESD resin.

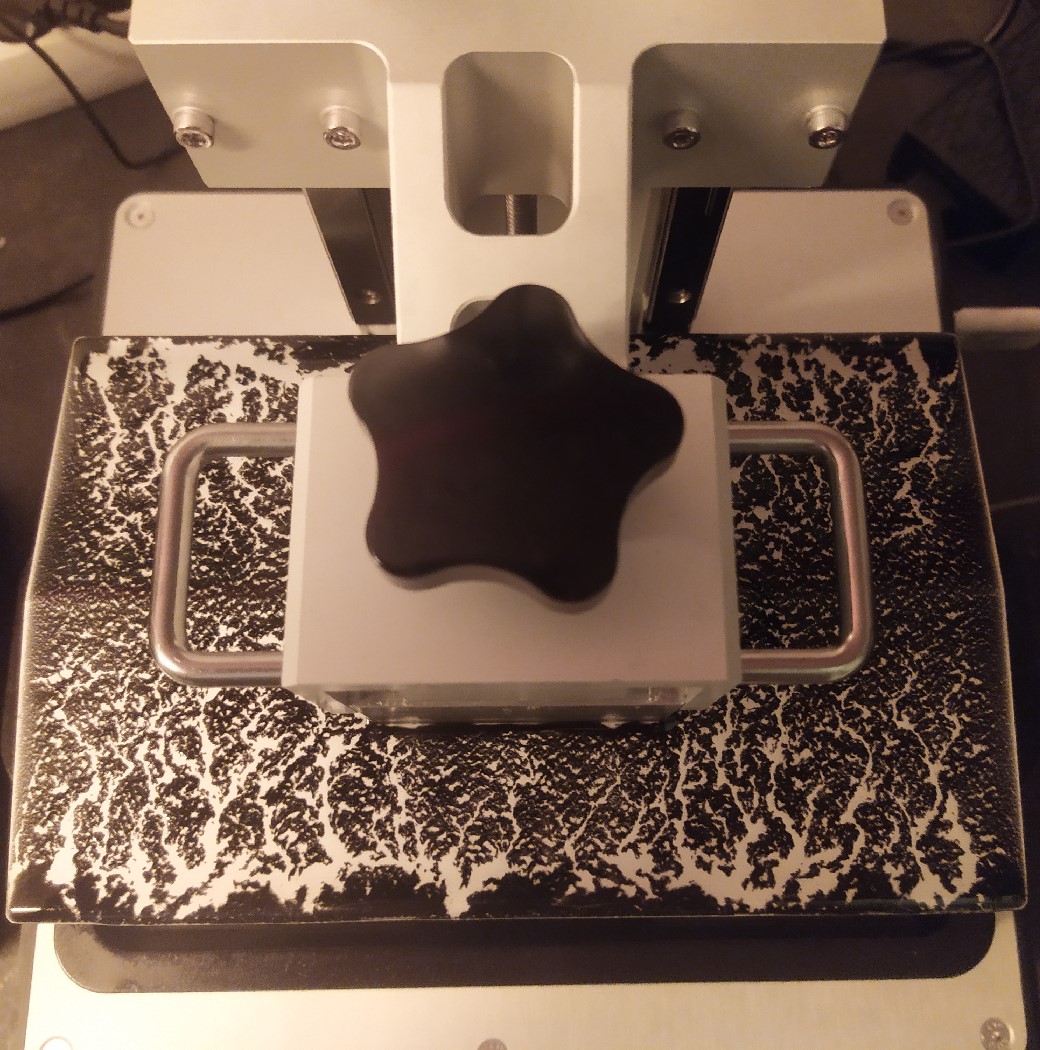

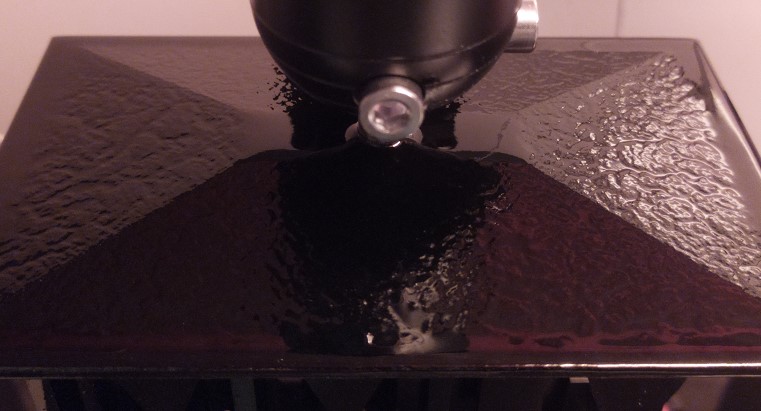

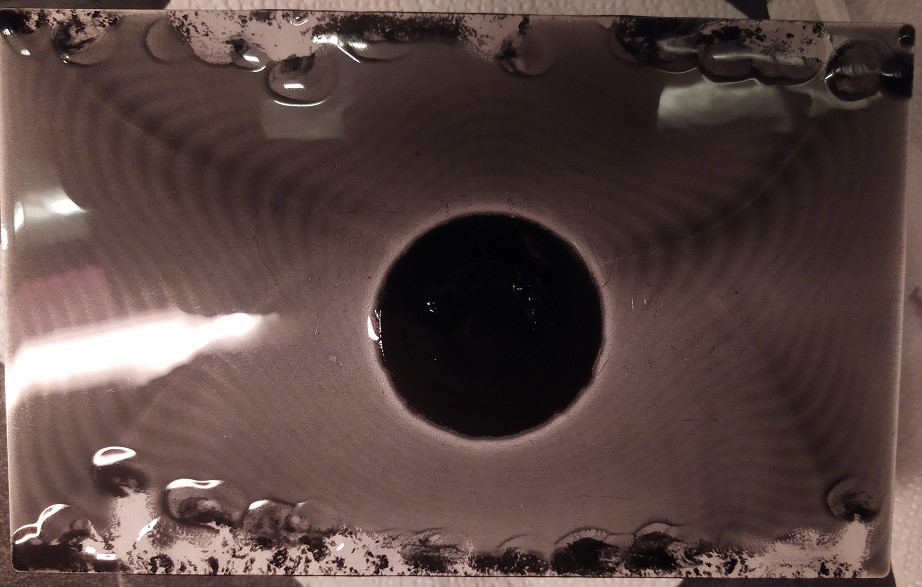

8) Resin patterns on build plate.

Liqcreate ESD resin has a different flow behavior compared to your regular resin. During printing or during extended period of waiting, strange structures can be formed on build plates like in the images below. This happens as the resin flows faster from a platform compared to the ESD additives which will deposit randomly. After printing, you can mix the extended resin back in the resin tank, even if it looks like this below:

Image: Structures of Liqcreate ESD resin on a grey platform from the Phrozen Sonic Mighty 4K.

Image: Structures of Liqcreate ESD resin on a black platform from one of the Elegoo Printers.

Image: Structures of Liqcreate ESD resin on a grey platform from one of the Anycubic printers.

After printing if you turn-around the build plate (where your part is located). Some similar structures can be visible. Same as the left-over resin on the build plate, just mix as much as you can back in the resin to re-use.

Image: Structures of Liqcreate ESD resin on a grey platform from the Phrozen Sonic Mighty 4K after printing, on the side were the parts are located.

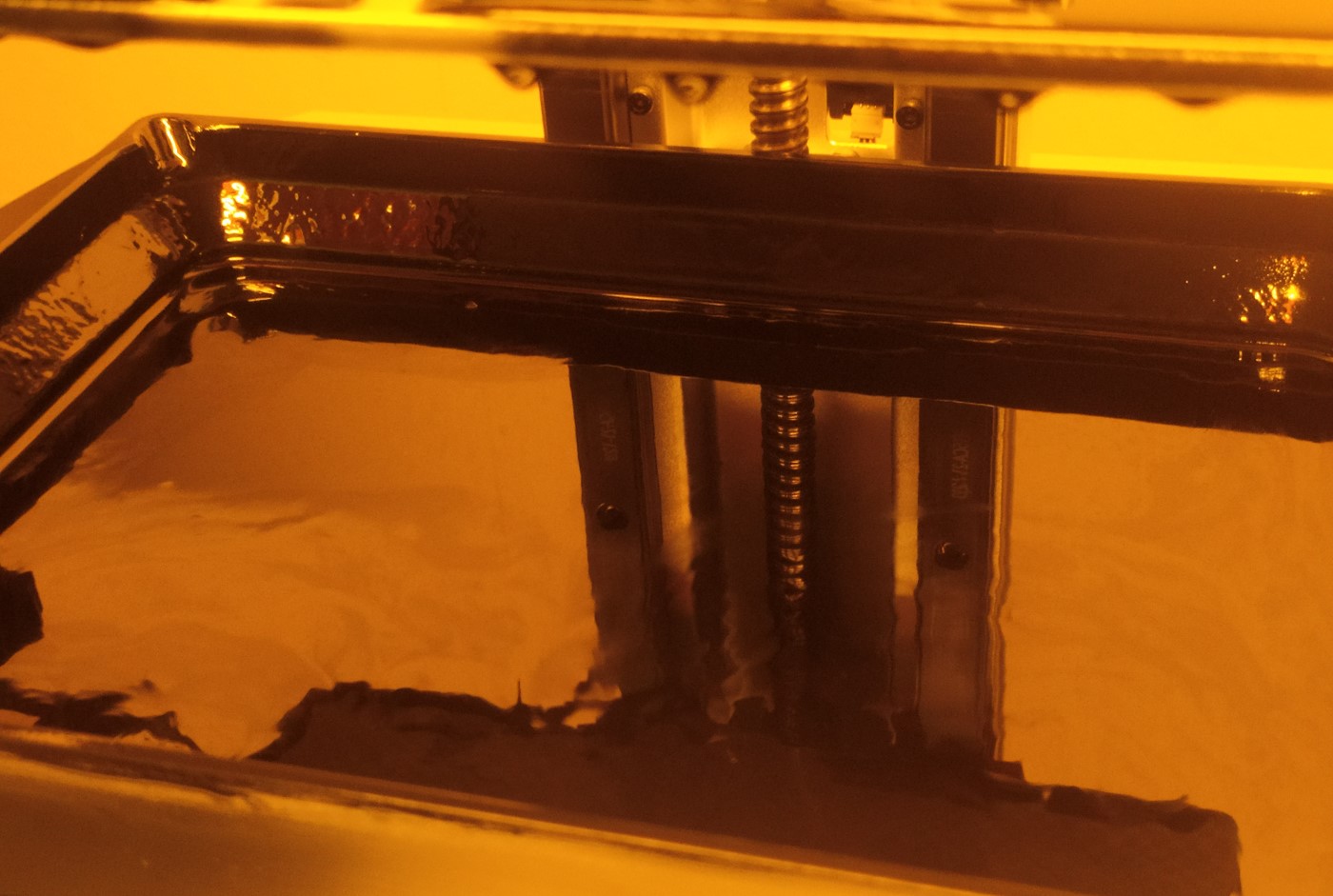

9) “Oily layer” on top of resin.

An oily layer can be visible on the resin as in the picture below. This is one of the components of the resin and this is normal.

Image: Oily-looking layer on top of Liqcreate ESD resin.

Image: Oily-looking layer on top of Liqcreate ESD resin.

10) Part surface finish.

The surface finish might be different compared to other black resins as the ESD additive can have a specific light reflection. When parts look fuzzy, then the print parameters are often not correct. Contact info@liqcreate.com for assistance. If your part has holes in the surface, that is due to trapped air bubbles in the resin. It is advised to not shake to rigorously before printing. if you did, then let the resin sit for a couple hours before printing.

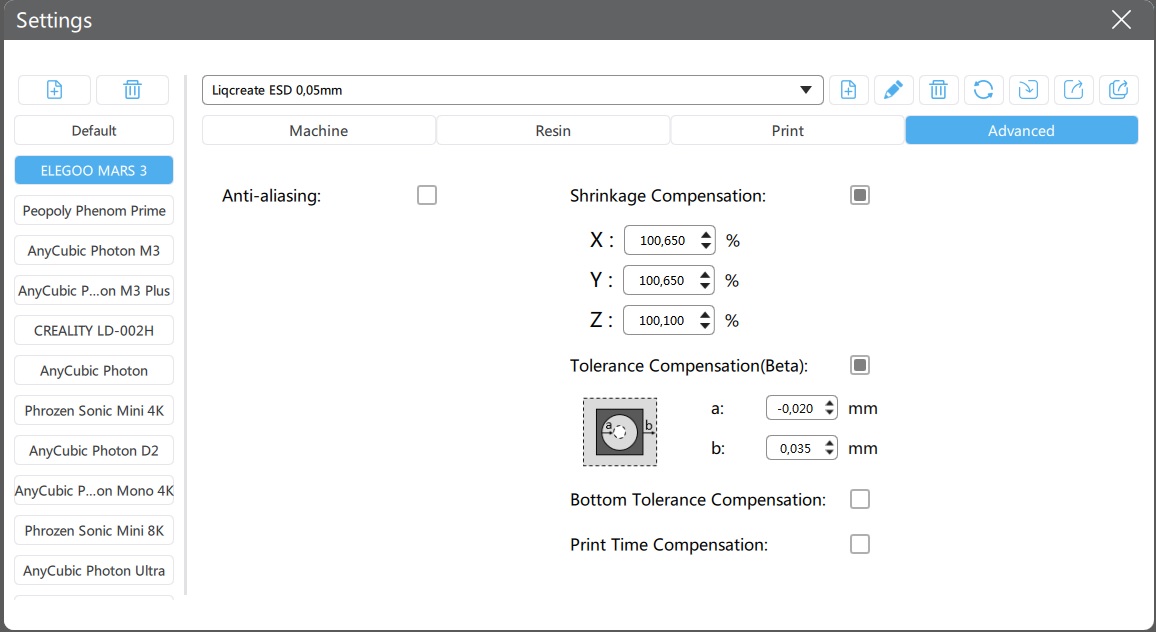

11) Shrinkage compensation.

Tested on the Elegoo Mars 3, the shrinkage compensation in Chitubox to get better accuracy can be found in the picture below. If you need super accurate parts, it is important to set the parameters right. For the Elegoo Mars 3 you can find the shrinkage factors below. For other printers you can look into our shrinkage optimization database.

Image: Shrinkage / tolerance compensation for Chitubox tested on the Elegoo Mars 3.

12) Resin temperature.

It is advised to print with Liqcreate ESD resin at least at 20°C / 68°F and maximum at 25°C / 77°F. printing at lower temperature causes random failure in the material.

13) Solving print failures with Liqcreate ESD resin.

There are a lot of common resin 3D-printing issues. In this article you can find 10 common resin 3D-printing fails and how to solve them. If you have need support, send is an e-mail at info@liqcreate.com and our technical team will try to assist.

14) Storage conditions.

Store the product in its original bottle, plug and cap at minimal 5°C / 41°F and maximum 30°C / 86°F. Avoid sources of heat, radiation, static electricity, sunlight and contact with food.

If you have any questions when working with Liqcreate ESD resin, send us an e-mail at info@liqcreate.com.