Post-processing is an essential part of resin 3D-printing to reach the final photopolymer properties. Printed parts need to be cleaned, dried and post-cured. The washing and drying steps are explained at the support article ‘how to post process SLA, DLP & LCD printed objects’. The next step that follows is post-curing.

Post-curing of resin 3D-printed parts

Post-processing is necessary to get the optimal properties out of your prints. If you use a stereolithography (SLA) 3D printer or a digital light processing (DLP) 3D printer, including LCD projectors, it’s essential to know how to post-process. Post-curing is an important post-process step.

Image of the Wicked Engineering Curebox post-curing unit with Liqcreate photopolymer resins

During 3D-printing, the resin is polymerized to a degree that it has exact dimensions and is solid enough to withstand peeling forces. This means it has reached a polymerization degree of 50 to 85%, depending on the resin and type of 3D-printer. Usually the best physical and mechanical properties are reached with a polymerization degree of > 95%, meaning that the printed parts have not reached their full potential and need some extra UV-light and/or temperature to get there. Several post-curing units are tested, The Wicked Engineering Curebox, the Mercury X wash & Cure Bundle and the Anycubic Wash & Cure 2.0.

Wicked Engineering Curebox post-curing resin

The Wicked Engineering CUREbox has 4 x 9 watt light output in the form of 365nm and 405nm LED’s. Time and temperature are the two variables to set. The high power output in this specific wavelength, and additional temperature help to get proper post-curing. The following list of post-curing settings were selected as recommended settings for Liqcreate resins:

Table 1: Post-Curing settings for the Wicked Engineering Curebox and Liqcreate resins

| Resin | Post-curing time (Minutes) | Temperature (°C) |

| Deep Blue | 30 | 60 |

| Stone Coal Black | 30 | 60 |

| Hazard Glow | 30 | 40 |

| Clear Impact | 30 | Room Temperature |

| Strong-X

(for general applications) |

30 | 60 |

| Strong-X

(For High-temp applications) |

120 | 60 |

| Flexible-X | 30 (first 5 minutes in water) | Room Temperature |

| Elastomer-X | 30 (first 5 minutes in water) | Room Temperature |

| Premium Flex | 30 (first 5 minutes in water) | Room Temperature |

| Tough-X | 30 | Room Temperature |

| Composite-X | 60 | 60 (optional additional thermal cure of 2 hours at 100°C) |

| Wax Castable | 15 | 60 |

| Premium White | 30 | 60 |

| Premium Black | 30 | 60 |

| Premium Model | 30 | 40 |

| Premium Tough | 30 | Room Temperature |

| ESD | 30 | 60 |

| Bio-Med Clear | 30 | 60 |

All mechanical data in the Liqcreate TDS are from UV post-cured samples from the Wicked Engineering Curebox. Two different post-curing settings were selected for Strong-X. A shorter post-curing cycle of 30 minutes at 60 degrees Celsius for general and engineering applications that don’t require the high temperature resistance and a longer post-curing cycle of 120 minutes at 60 degrees Celsius for high-temperature applications. This long cycle will increase the temperature resistance of Strong-X, and also makes the product slightly more brittle, which might limit the usage for general engineering applications.

The settings found for the Wicked Engineering Curebox can also be used on similar post-curing units. For instance the Formlabs Form Cure. The Formlabs Form Cure works with only 405nm light, but with a build-in heater, the Formlabs Form Cure can achieve complete polymerization as well.

Post-curing in the Anycubic Wash & Cure 2.0, Elegoo Mercury X and alternative post-curing units

There are quite a few entry-level UV post-curing units for 3D-printing resins on the market. Compared to the earlier mentioned Wicked Engineering Curebox and Formlabs Form Cure, they often don’t work with controlled temperature and the power of the LED’s is often less. Two alternative post-curing units were tested, the Anycubic Wash & Cure and the Elegoo Mercury X. Mechanical properties of several resins was measured and the advised post-curing settings can be found below.

Post-curing advise for the Anycubic Wash & Cure 2.0

The Anycubic Wash & Cure 2.0 is simple UV post-curing unit with 405nm LED. There is a timer present to set it to maximum 60 minutes per cycle. For extended use, the timer has to be set multiple times. As there is no temperature setting available, UV post-curing takes place at room temperature. Below the advised settings and measured mechanical properties at each UV post-curing step can be found.

Table 2: Post-Curing settings for the Anycubic Wash & Cure 2.0 and Liqcreate resins

| Resin | Post-curing time (Minutes) | Remark |

| Deep Blue | 30 | |

| Stone Coal Black | 30 | |

| Hazard Glow | 30 | |

| Clear Impact | 60 | |

| Strong-X

(for general applications) |

120 at 80°C | Not possible to achieve complete cure |

| Strong-X

(For High-temp applications) |

n/a | Not possible to achieve complete cure |

| Flexible-X | 30 (first 5 minutes in water) | |

| Elastomer-X | 30 (first 5 minutes in water) | |

| Premium Flex | 30 (first 5 minutes in water) | |

| Tough-X | 30 | |

| Composite-X | n/a | Not possible to achieve complete cure |

| Wax Castable | 30 | |

| Premium White | 30 | |

| Premium Black | 30 | |

| Premium Model | 60 | |

| Premium Tough | 30 | |

| ESD | 30 |

Mechanical properties of critical materials, UV post-curing in the Anycubic Wash & Cure 2.0

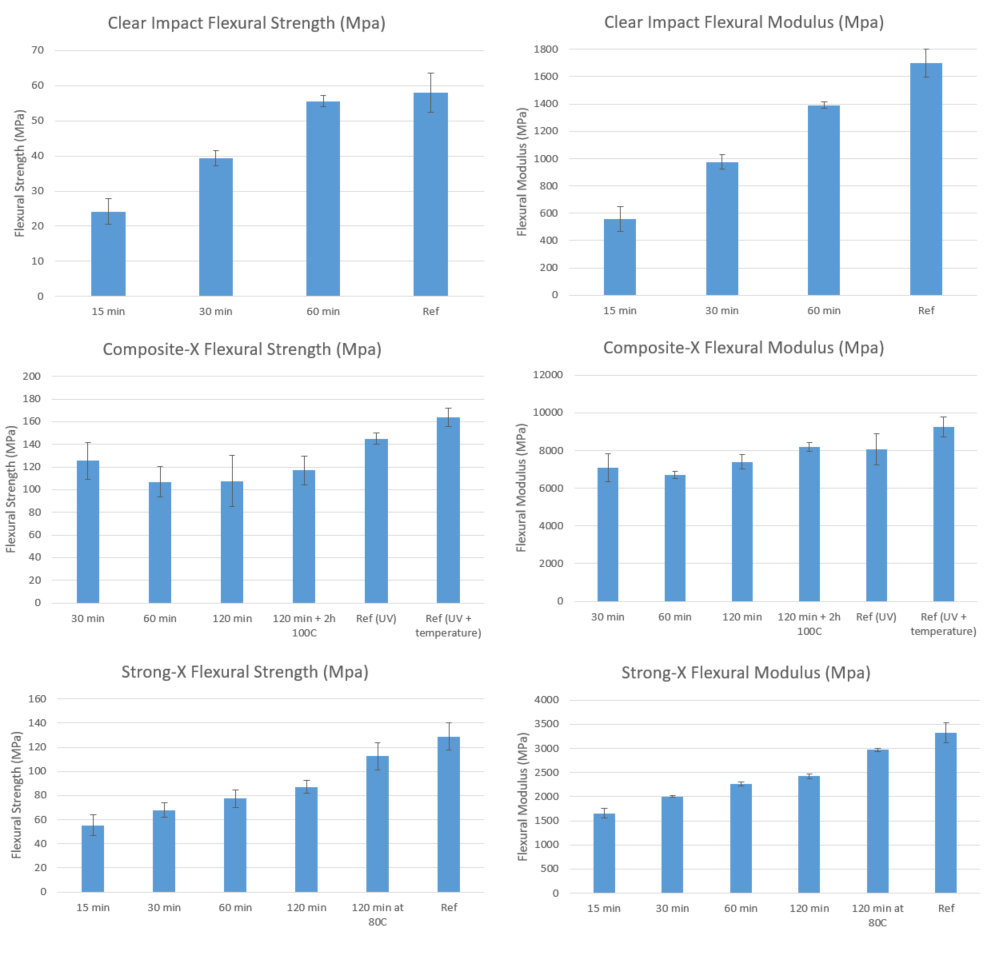

The three materials were selected for the UV post-curing trials, Clear Impact, Strong-X and Composite-X. Mechanical test specimen were 3D-printed in Z-axis and benchmarked against the reference. The reference are the properties achieved by post-curing with the advised settings of the Wicked Engineering Curebox, these are also the values published in our technical data sheets.

Graphs of the flexural properties of Clear Impact, Strong-X and Composite-X, UV post-cured in the Anycubic Wash & Cure device.

From the data it is evident that the Anycubic Wash & Cure is struggling to fully post-cure the critical engineering grade 3D-printing resins. For Clear Impact, nearly the end properties are achieved by post-curing for an hour. For Strong-X, it is impossible to get good properties by just UV-light of the Anycubic post-curing unit. One of the main issues is that the device cures at room temperature, and that you would need some temperature to reach Strong-X’s full potential. By UV post-curing the part for 60 minutes, then placing the part in an 80°C oven and cure again for 60minutes while the part is still warm, better properties are achieved. But is still remains difficult and extra steps are required to get close to the properties achieved by the Wicked Engineering Curebox. With Composite-X it is possible to get a good rigidity in the material by just post-curing with the Anycubic Wash & Cure for 120 minutes. However, in strength it is nearly impossible to reach values over 120 MPa. For both Strong-X and Composite-X, a more advanced UV post-curing unit, like the Wicked Engineering Curebox is required.

Post-curing advise for the Elegoo Mercury X

Similar to the Anycubic Wash & Cure 2.0, The Elegoo Mercury X is simple UV post-curing unit with 405nm LED. With its 36Watt operating power, it is more powerful than the Anycubic Wash and Cure 2.0. There is a timer present to set it to maximum 30 minutes per cycle. For extended use, the timer has to be set multiple times. As there is no temperature setting available, UV post-curing takes place at room temperature. Below the advised settings and measured mechanical properties at each UV post-curing step can be found.

Table 2: Post-Curing settings for the Elegoo Mercury X and Liqcreate resins

| Resin | Post-curing time (Minutes) | Remark |

| Deep Blue | 30 | |

| Stone Coal Black | 30 | |

| Hazard Glow | 30 | |

| Clear Impact | 60 | |

| Strong-X

(for general applications) |

n/a | Not possible to achieve full cure |

| Flexible-X | 30 (first 5 minutes in water) | |

| Elastomer-X | 30 (first 5 minutes in water) | |

| Premium Flex | 30 (first 5 minutes in water) | |

| Tough-X | 30 | |

| Composite-X | n/a | Not possible to achieve full cure |

| Wax Castable | 30 | |

| Premium White | 30 | |

| Premium Black | 30 | |

| Premium Model | 60 | |

| Premium Tough | 30 | |

| ESD | 30 |

Mechanical properties of critical materials, UV post-cured in the Elegoo Mercury X UV post-curing unit

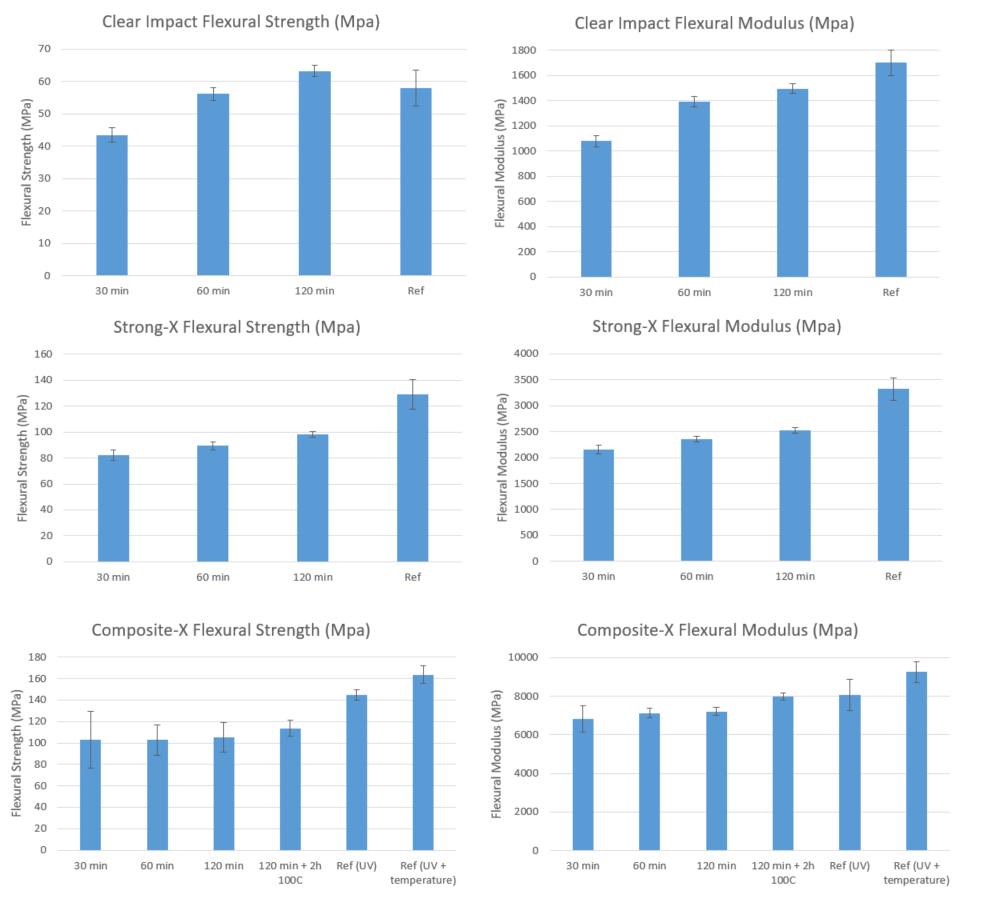

Identical as to the previous test, the three materials were selected for the UV post-curing trials, Clear Impact, Strong-X and Composite-X. Mechanical test specimen were 3D-printed in Z-axis and benchmarked against the reference. The reference are the properties achieved by post-curing with the advised settings of the Wicked Engineering Curebox, these are also the values published in our technical data sheets.

Graphs of the flexural properties of Clear Impact, Strong-X and Composite-X, UV post-cured in the Elegoo Mercury X UV post-curing unit.

The Elegoo Mercury X can come very close to the reference cured samples of Liqcreate Clear Impact. The 60 and 120 minutes cured samples were very good in its strength, while full rigidity was quite close for the 120 minutes cured sample. For Strong-X no full cure was achieved, even not at 120 minutes post-curing. The temperature in the post-curing unit is just too low to get towards a strength of above 100 MPa. With Composite-X not much changed in the samples that were cured for 30 minutes or 120 minutes. A modulus of around 7 GPa was achieved, while the reference is in the range of 9 – 9,5 GPa. Unfortunately the strength is even more off with just a strength in the range of 100 MPa while the reference samples are more towards the 145 to even 165 MPa for the thermally cured sample.

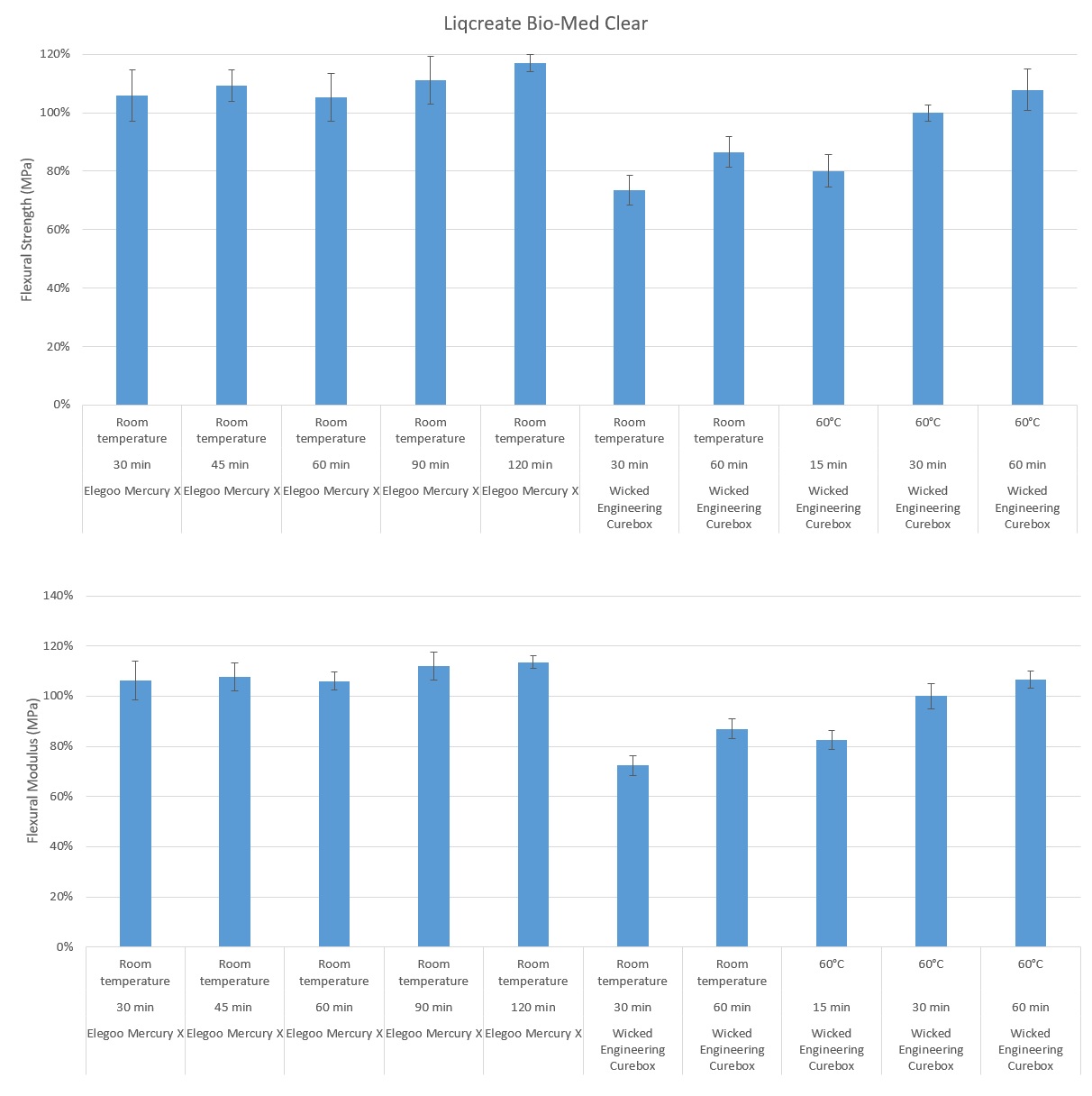

Post-curing Bio-Med Clear – Biocompatible 3D-printing resin – in the Elegoo Mercury X.

With most resins we can advise multiple post-curing units to reach somewere near the maximum properties. This is different for Liqcreate Bio-Med Clear as the biocompatibility testing has been executed on samples cured in the Wicked Engineering Curebox. Changing this can lead to parts that do not pass this biocompatible criteria anymore.

Similar as with the previous materials we tested a range of post-curing devices and cycles. In most enginieering materials it can be found that the entry level curing units do not yield good results. Surprisingly for Liqcreate Bio-Med Clear, the mechanical properties after curing in the Elegoo Mercury X were similar, if not better compared to the professional Wicked Engineering Curebox. It seems that this curing unit can work well with Bio-Med Clear from the mechanical properties perspective. That said, there is no evidence in biocompatibility testing that this curing unit will also yield biocompatible end parts.

Post-curing Liqcreate Bio-Med Clear, post-curing settings vs. mechanical properties.

Post-curing advise for the Asiga Flash post-curing unit

The Asiga Flash cure or Pico Flash is a bit different compared to the previously tested post-curing units. It is a smaller unit and has 4 fluorescent lamps of 365nm and 9 Watts power per lamp. All Liqcreate resins can cure at 365nm, but it should be experimentally determined if the temperature and wavelength can cure the parts well enough. There is a timer present to set it to maximum 30 minutes per cycle. For extended use, the timer has to be set multiple times. As there is no temperature setting available, UV post-curing takes place at room temperature. Below the advised settings and measured mechanical properties at each UV post-curing step can be found.

Table 2: Post-Curing settings for the Asiga Flash and Liqcreate resins

| Resin | Post-curing time (Minutes) | Remark |

| Deep Blue | 30 | |

| Stone Coal Black | 30 | |

| Hazard Glow | 30 | |

| Clear Impact | n/a | Insufficient cure |

| Strong-X | n/a | Insufficient cure |

| Flexible-X

Elastomer-X |

n/a

n/a |

Insufficient cure

Insufficient cure |

| Tough-X | n/a | Insufficient cure |

| Composite-X | n/a | Insufficient cure |

| Wax Castable | 30 | |

| Premium White | 30 | |

| Premium Black | 30 | |

| Premium Model | 60 | |

| Premium Tough | 30 | |

| Premium Flex

ESD |

30

30 |

Mechanical properties of critical materials, UV post-cured in the Asiga Flash UV post-curing unit

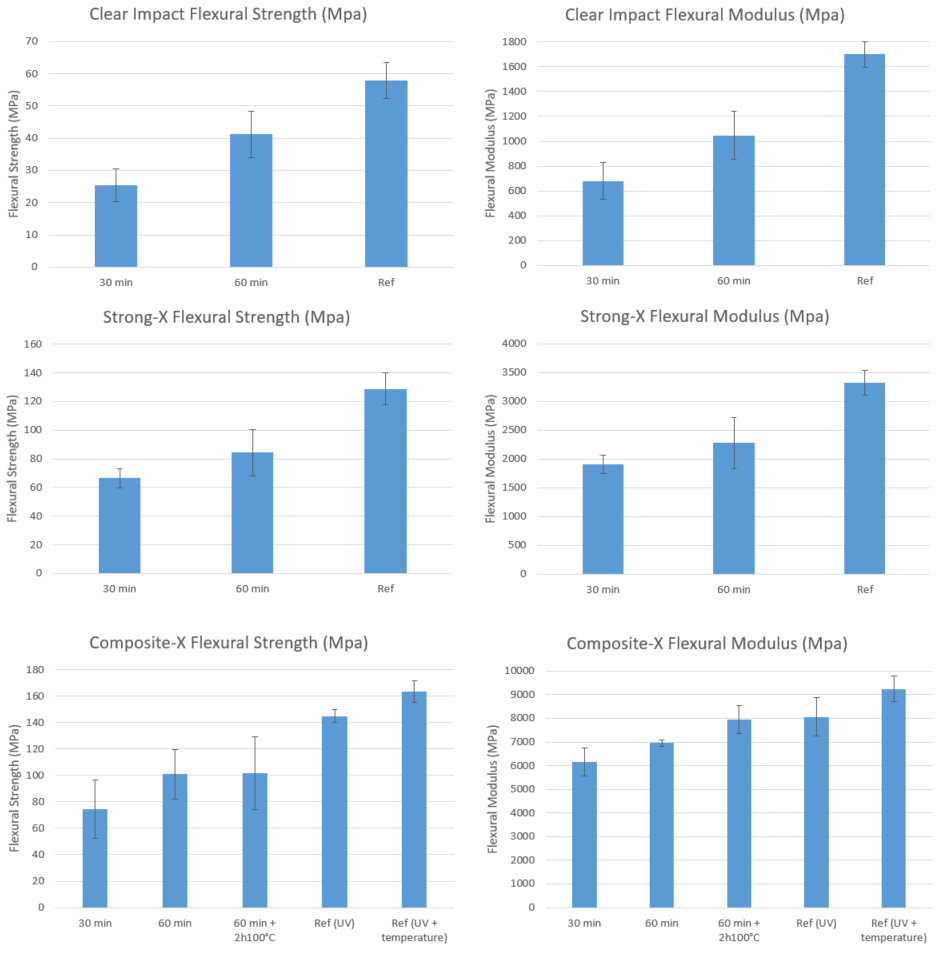

Identical as to the previous test, the three materials were selected for the UV post-curing trials, Clear Impact, Strong-X and Composite-X. Mechanical test specimen were 3D-printed in Z-axis and benchmarked against the reference. The reference are the properties achieved by post-curing with the advised settings of the Wicked Engineering Curebox, these are also the values published in our technical data sheets.

Graphs of the flexural properties of Clear Impact, Strong-X and Composite-X, UV post-cured in the Asiga Flash or Pico Flash UV post-curing unit.

After the first tests it was apparent that the 365nm fluorescent bulbs were not post-curing the materials properly. This could be due to the wavelength, as generally known 365nm is efficient for surface cure, but 400nm wavelength is best for deeper cure. Or the temperature in the post-curing unit is not high enough. The three tested critical materials Clear Impact, Strong-X and Composite-X could not be cured to full conversion. Even in some parts we were getting good values, but inhomogeneous cure lead to high standard deviations and scattered results. Therefor for the critical materials it is advised to choose for a Wicked Engineering Curebox or similar post-curing unit.

MeccatroniCore BB-Midi Plus UV-curing unit & Liqcreate resins

Engineers at Liqcreate had a chance to test the MeccatroniCore BB-Midi Plus post-curing unit in combination with Liqcreate resins. Read the full story and specifications here and find the curing tables below.

Table: Curing temperature and time per resin in the MeccatroniCore BB-Midi Plus UV-curing unit.

| Resin | Post-curing time (Minutes) | Temperature (°C) |

| Deep Blue | 15 | 30 |

| Stone Coal Black | 15 | 60 |

| Hazard Glow | 15 | 30 |

| Clear Impact | 15 | 60 |

| Strong-X | 30 | 60 |

| Flexible-X | 30 | 30 |

| Tough-X | 30 | 30 |

| Composite-X | 30 | 60 |

| Wax Castable | 15 | 30 |

| Premium White | 15 | 30 |

| Premium Black | 15 | 60 |

| Premium Model | 15 | 30 |

| Premium Tough | 15 | 30 |

| Premium Flex | 15 | 30 |

| Dental Model Pro Beige | 15 | 30 |

| Dental Model Pro Grey | 15 | 30 |

| Gingiva Mask | 15 | 30 |

Can I over-cure a resin 3D-printed part?

Technically seen, yes you can over-cure a part. Will this happen in reality, probably not! From the results published above, you can see that when you fully cure a photopolymer resin, you need quite some UV energy and temperature to reach its final properties. After that, when for instance you place a part in the sun for many months, a part can be over-cured and loose some of its properties, or become brittle. You can read more about this effects and our internal study on UV-aging of 3D-printing resins here.

If you look online, a lot of people are talking about over-curing resins when post-curing for minutes and they see that the part becomes brittle when post-curing too long. What actually happens, is that the resin itself is brittle in its fully cured state, and that the people are just under-curing it to get rid of this brittleness. It is possible to do this, however, the part can cure in time and go towards a fully cured state in the sun or on your desk in a matter of weeks. Then it can become brittle. What you actually need is to choose for a resin that is tough in its fully cured state, like Clear Impact, Premium Tough and Tough-X. These resins will not get brittle in time with proper post-curing!

Why is temperature so important when UV-curing 3D-printing resins?

As you might have noticed from the results published above, temperature is an important factor when post-curing engineering grade resins. To explain why this is important, we have to look at how the properties are changing during post-curing. When a part is printed and not post-cured yet, it can have a polymerization grade, or conversion, of 50-85%. The part feels much more bendable than a post-cured part. When UV post-curing the part, the conversion goes up and the properties change. One of these properties is the Tg (Glass transition temperature). This is the temperature at which the polymer is still soft and a bit bendable. If you increase the temperature during UV post-curing, the part gets a bit softer, and the polymerization process inside the polymer much more efficient and can reach a higher degree of conversion. That is why you can reach a higher degree of conversion and also unlock different mechanical properties.

What about other alternative UV post-curing units?

Next to the four popular ones mentioned and measured above, there are a lot of UV post-curing chambers or curing units the market today. It is impossible to test all of the curing units available. Therefor we will list the most used UV curing chamber, take a look at the specifications and provide UV post-curing guidelines based on the technical specifications of the manufacturer and our experience with similar curing units.

Formlabs Form Cure and Formlabs Form Cure L are two popular curing units in the prosumer and professional sector. Both UV post-curing units have a build-in heater and powerful LED’s. On specifications the Formlabs Form Cure and Form Cure L have similar output compared to the Wicked Engineering Curebox and therefor similar curing is advised.

Video by Formlabs: The Formlabs Form Wash & Cure machines

Next to the two tested UV curing units of Elegoo and Anycubic, they offer a few alternatives. The Elegoo Mercury, the Elegoo Mercury Plus 2.0, the Elegoo Mercury Plus and the Anycubic Wash & Cure Machine 2.0. Looking at the specifications, the Anycubic Wash & Cure machine 2.0 has similar specifications compared to the tested Elegoo Mercury X, mentioned in the beginning of the article. While the three Elegoo Curing units, the Elegoo Mercury, Elegoo Mercury Plus and Plus 2.0 have similar specifications as the Anycubic Wash and Cure. Similar settings as listed above, are advised for these four UV curing machines.

Creality has launched two affordable machines, one for washing and curing, and one solely for curing. The Creality SL 1 curing machine looks very similar to the first Elegoo Mercury UV curing unit. With its relatively low power, it has quite some similarities with the Anycubic Wash and Cure, which was tested before. Although the Creality UW-01 Washing and Curing has better LED’s in the region of 385 and 405nm, it does not heat the parts. Therefore ultimate UV post-curing is difficult for critical materials. Settings of the Elegoo Mercury X are a good starting point.

With its 40Watt 405nm LED’s and no additional heating options, the Phrozen Cure Luna is an entry model UV post-curing unit. Settings will likely be similar than the Anycubic Wash and Cure tested earlier. The more powerful and bigger Phrozen Cure Mega is more like the tested Elegoo Mercury X. The UV curing units Wanhao Boxman and the B9Creator B9 Model Cure both have quite powerful LED’s and expected similar needed post-curing settings as the Elegoo Mercury X, published earlier in this article.

XYZ 3D-printing launched its XYZ UV Curing Chamber. The XYZ UV Curing chamber is equipped with 60 Watt LED’s with a wavelength range of 375 – 405nm. As no additional heater is applied, settings will likely be similar than the Asiga Flash UV curing chamber found above. Little is known about the new Shining 3D FabCure UV post-curing machine. With its 405nm LED and no visible heaters present, it is likely that you would need similar post-curing times compared to the Elegoo Mercury X.

We are finishing the list with three powerful UV curing units, the Nextdent LC-3Dprint Box, 3D-systems Figure 4® UV Curing Unit 350 and Ackuretta Curie UV post-Curing unit are used to post-cure biocompatible materials and most have heating options or a warm curing chamber by default. UV post-curing times and settings of the Wicked Engineering Curebox are good initial settings to start with.

Additional information on post-curing 3D-printing resins

All resins suffer from oxygen inhibition, which means that oxygen will have a negative effect on the curing. This can result in surface stickiness. To avoid stickiness it is important that parts are properly washed and processed, more information about the processing of printed parts can be found here. Flexible-X is in general sensitive to this effect and is therefore advised to be cured in an oxygen free environment. This can either be done to post-cure parts in a water- or glycerol bath or cure the parts under a nitrogen flow.

If mechanical properties are important for your project, it is not recommend to under-cure the parts, or use undefined curing methods like sunlight curing. Under-cured parts have the tendency to be softer, weaker and properties might change over time. Curing with undefined methods like sunlight will likely give variable results due to the variable amount of UV-light and temperature on the 3D-printed parts. Many curing boxes devoted to 3D printing, like the Wicked engineering CUREbox, are compatible with Liqcreate resins. Before using a UV curing chamber, please check the settings (light intensity, temperature capabilities etc.).

Hope this was an educational and interesting read. All that remains is to wish you good luck with the post-curing of your 3D object. If there are any questions, please contact Liqcreate at info@liqcreate.com.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!