Liqcreate Composite-X is one of the stiffest and strongest resins available in the market. With a flexural modulus over 9000 MPa and a flexural strength of 150 – 170 MPa it is superior to almost all photopolymer resins currently available. Liqcreate Composite-X is fairly easy to use for experience users on all open SLA, DLP and MSLA 3D-printers in the range of 385 – 405nm. The composite 3D-Print resin can be used after UV-post curing, or the properties can be boosted with a thermal cure. This material has features like excellent chemical resistance, high strength and high stiffness which makes it ideal for wind tunnel testing, fluid flow components, automotive and heavy duty industrial applications. In this article explains best practices for our composite 3d-print resins. Please note, this resin is advised for experienced users. If you are new to 3D-printing with resins, it is good to start with a easier resins like Liqcreate Premium Black.

In this article the following topics are explained:

- 1) Post-curing of Composite-X

- 2) Composite-X 3DPrinter compatibility and setting

- 3) Support settings for Composite-X

- 4) Questions and Answers

- – Does that mean I can’t print with Composite-X on the machines that do not offer anodized platforms / parts?

- – How about platform wear and replacement after 3d-printing with composite resins?

- – How does this abrased platform look after printing with Composite-X?

- – How to clean the platform properly?

- – The composite resin has a darker color or black spots, what to do?

- – Why do some parts have a grey bottom surface while other parts are white?

- – Why are there small holes in my printed part after washing?

- – Why is the surface of my 3D-print composite part chalky and how to avoid this?

- – How to wash and post-process parts made of composite resins?

- – Print is stuck on my platform, how to take it off?

- – I want to pour the composite resin back in the bottle and there is a residue left, what to do

- – Why does my FEP film look dull after printing with composite resins

- – Why is there a semi-solid film on the top of my platform after printing a long job?

1) Post-curing vs Mechanical properties of Composite-X

Composite-X is completely different compared to any other 3D-Print resins developed by Liqcreate to date. It is a nano-micro ceramic reinforced composite material. The ceramic particles make the resin extremely stiff, strong and also reduces the shrinkage to an absolute minimum. The complete set of mechanical properties of composite can be found here.

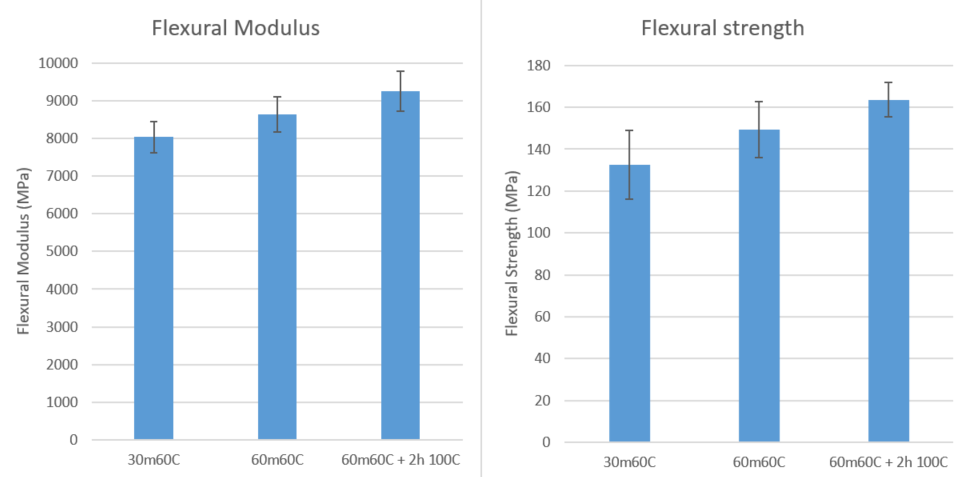

A whole set of post-processing options are tested by the Liqcreate engineers and a summary of the effect on the mechanical properties are explained below. All 3d-printed composite samples were UV post-cured at 60 degrees Celsius in a Wicked Engineering Curebox. The data sets in the middle and left were post-cured with UV light only with respectively 30 and 60 minutes. The data set on the right was thermally post-cured for 2 hours at 100 degrees Celsius in an conventional oven after a 60 minutes UV post-curing cycle.

A thermal post-cure is necessary for composite to reach to 150 – 170 MPa in Flexural Strength and reach up to 9,5 GPa Flexural Modulus. Two other factors which can influence the mechanical properties are the sample/3D-Print quality and heat-up/cool-down rate of the thermal curing step.

2) Composite 3D-print resin & 3D-Printer compatibility

At Liqcreate we try to run our resins on as many 3D-printers possible. The 3D-print resins are being optimized with the 3D-printers in our laboratory and also partners are working on creating settings for Composite-X on different platforms. For more information about 3D-print parameters and settings on your 3D-printer, please visit our website or send an e-mail to info@liqcreate.com.

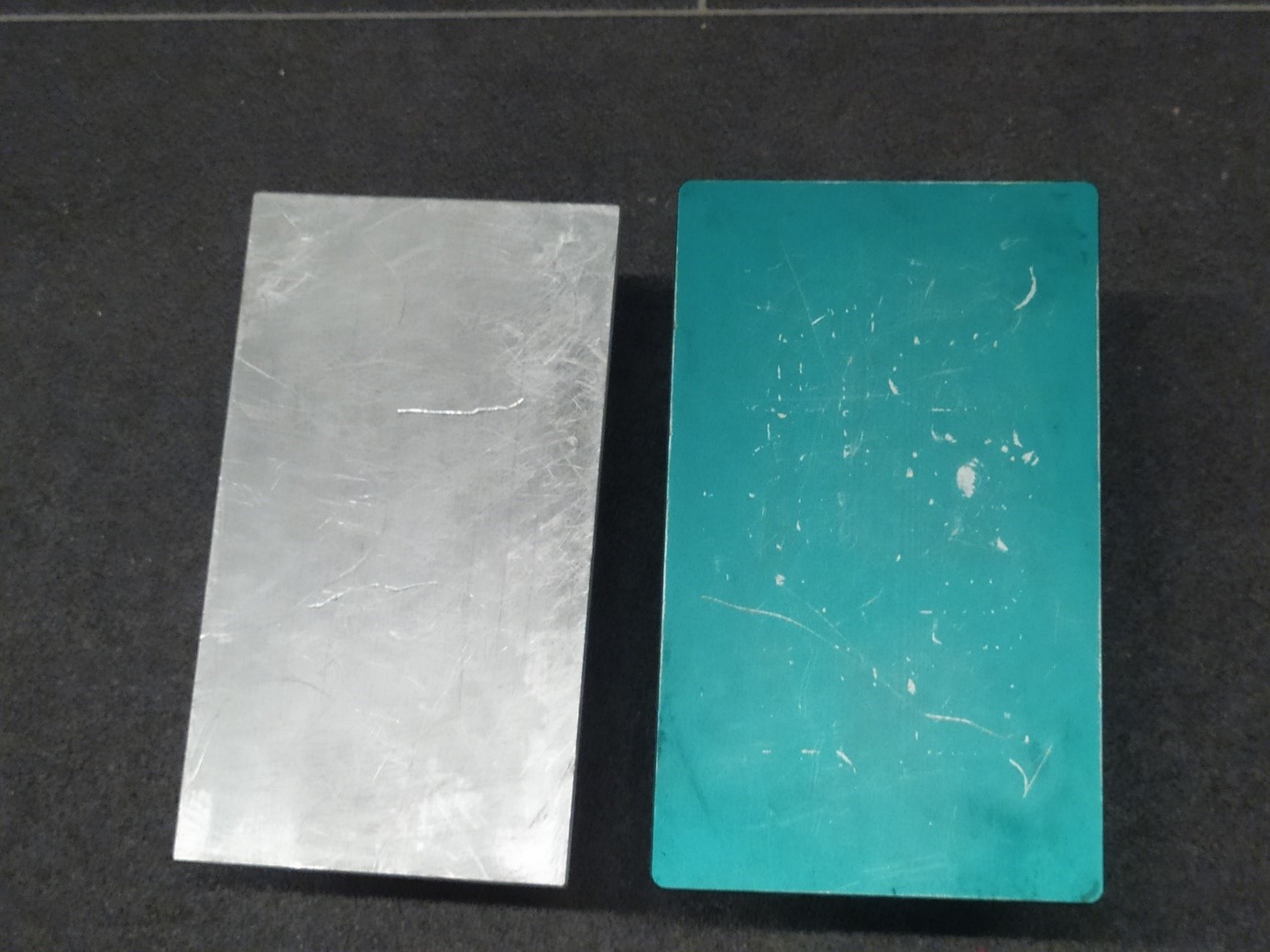

Due to the ceramic particles in Composite-X, it has an abrasive effect on aluminum parts. The best equipment would be anodized aluminum or coated aluminum for the resin tanks. On the left side is a CNC milled aluminum platform which will have suffer from abrasion and on the right side a anodized aluminum platform which will not.

3) Support settings for Composite-X

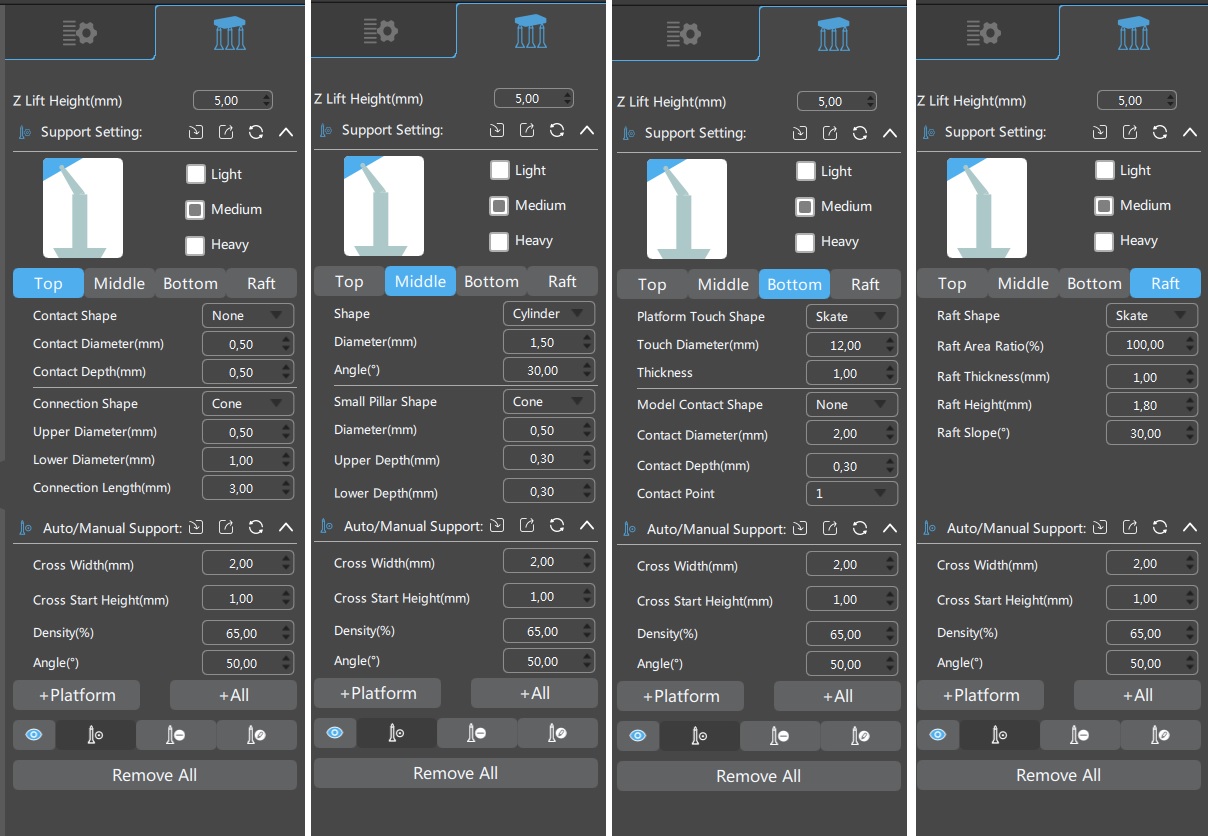

Support settings are depending on the type of resin in combination with the type of printer, release mechanism, material on the bottom of the resin tank and also the secondary settings like print speed. With the extreme growth of available resin 3D-printers in the past years, it is impossible to give validated support settings for each printer. In this section you can find settings for some generic printers, design and print speed.

Image: generic support settings used to succesfully print the test-files with Composite-X

4) Questions & answers:

In this section you will find a lot of tips, tricks and answers to the most common questions when 3D-printing composite resins. If your question is not answered here, please contact us at info@liqcreate.com.

Does that mean I can’t print with Composite-X on the machines that do not offer anodized platforms / parts?

No it doesn’t. You can still print perfect parts but it will take more time and effort to clean your equipment.

How about platform wear and replacement after 3d-printing with composite resins?

We are running Composite-X for more than 6 months on printers with aluminum platforms and have not replaced a platform yet.

How does this abrased platform look after printing with Composite-X?

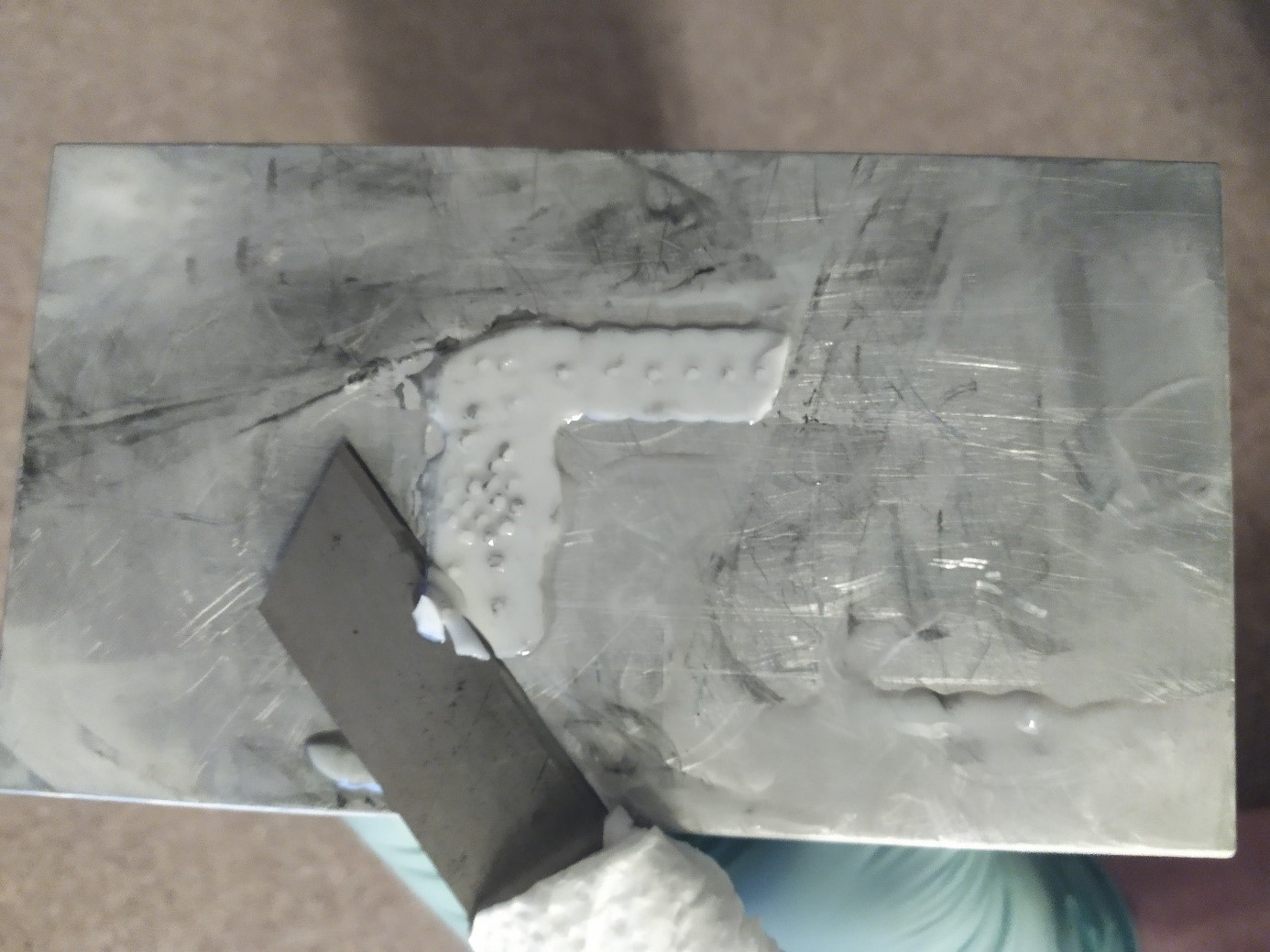

Below you see a picture of the platform after printing. It has black spots all over the platform when you rub it.

How to clean the platform properly?

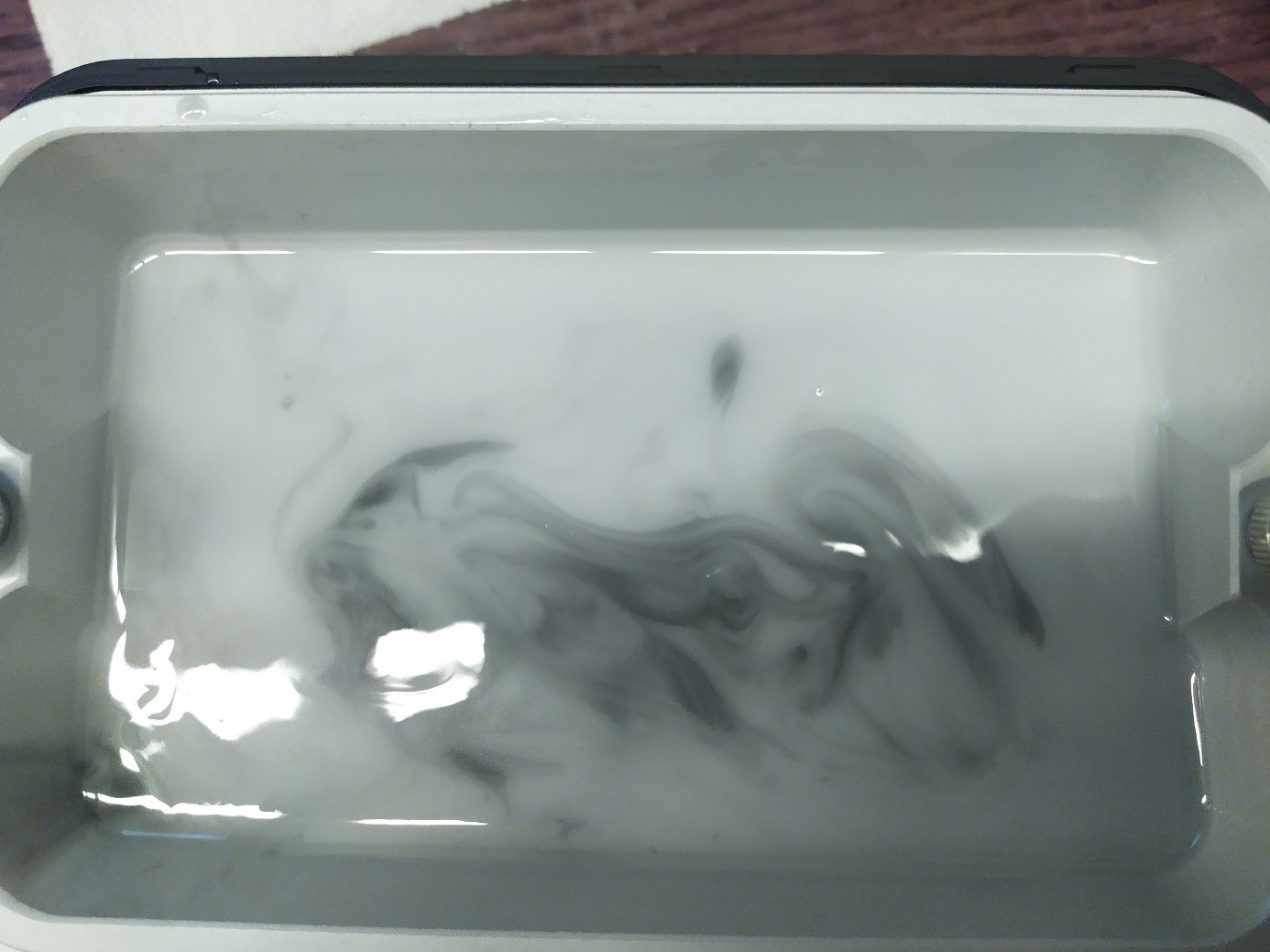

First take the object off and wipe the platform clean with a dry paper towel. Then clean the platform with IPA / Ethanol / Resin Cleaner and you will see that the paper towel gets black, just like the picture below. Then wipe the platform with a dry paper towel and you will get more black residue off. Repeat this for 3 times until your dry wipe is not giving off any black residue anymore.

The composite resin has a darker color or black spots, what to do?

During printing, the aluminum platform can give off some black color to the resin. If it is as much as in the first picture, you are good to go. If the platform was not cleaned properly after a print with Composite-X, the platform can give off more black material to the resin. For example in the second picture below. This will much contamination will lead to inferior properties and it is advised to either discard or remove the contaminated resin.

Why do some parts have a grey bottom surface while other parts are white?

Parts placed directly on an aluminum platform can have a grey bottom surface. This usually does not affect the properties. This can be eliminated by placing the parts on supports, or by cleaning the platform more extensively before printing.

Why are there small holes in my printed part after washing?

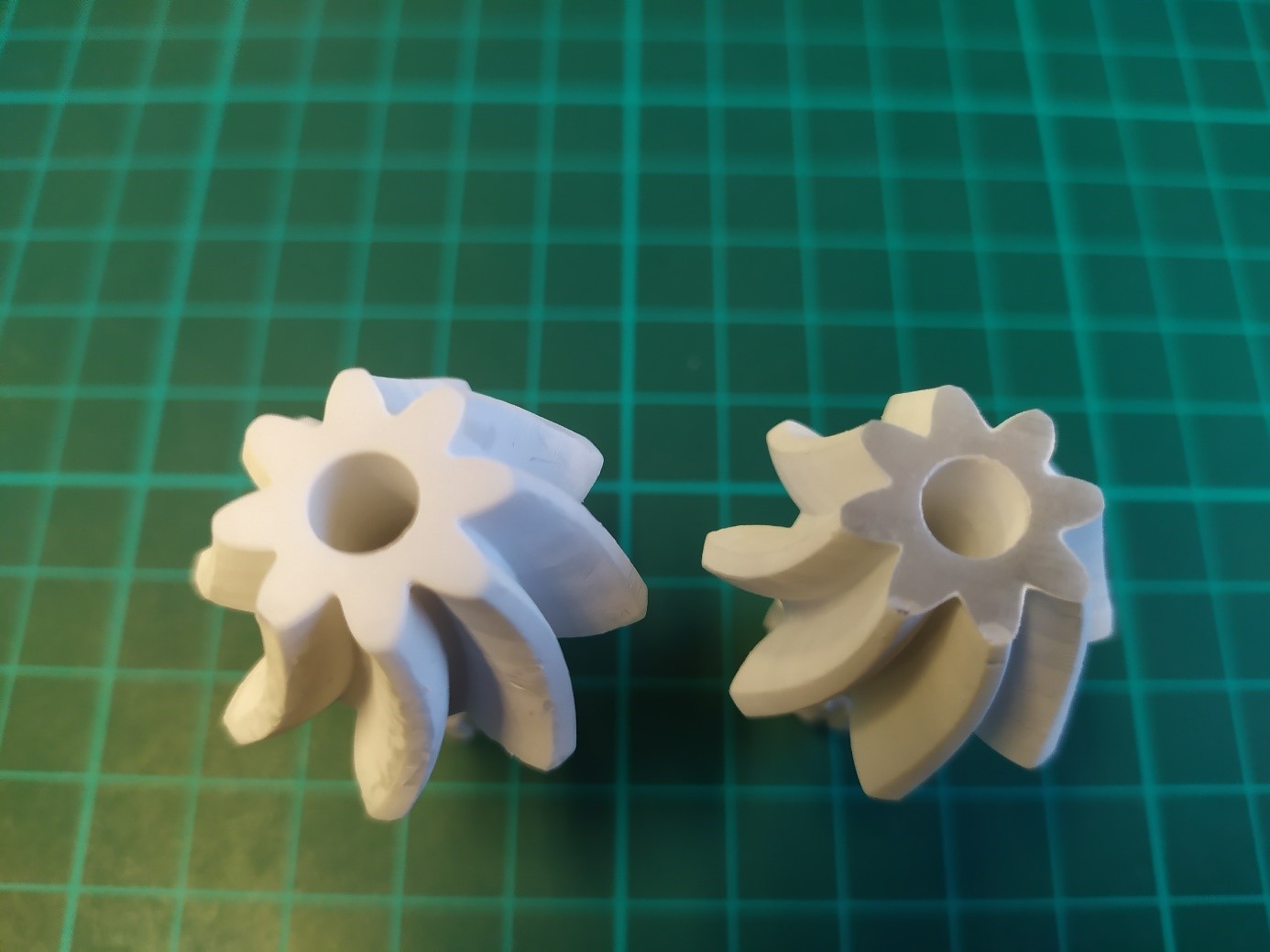

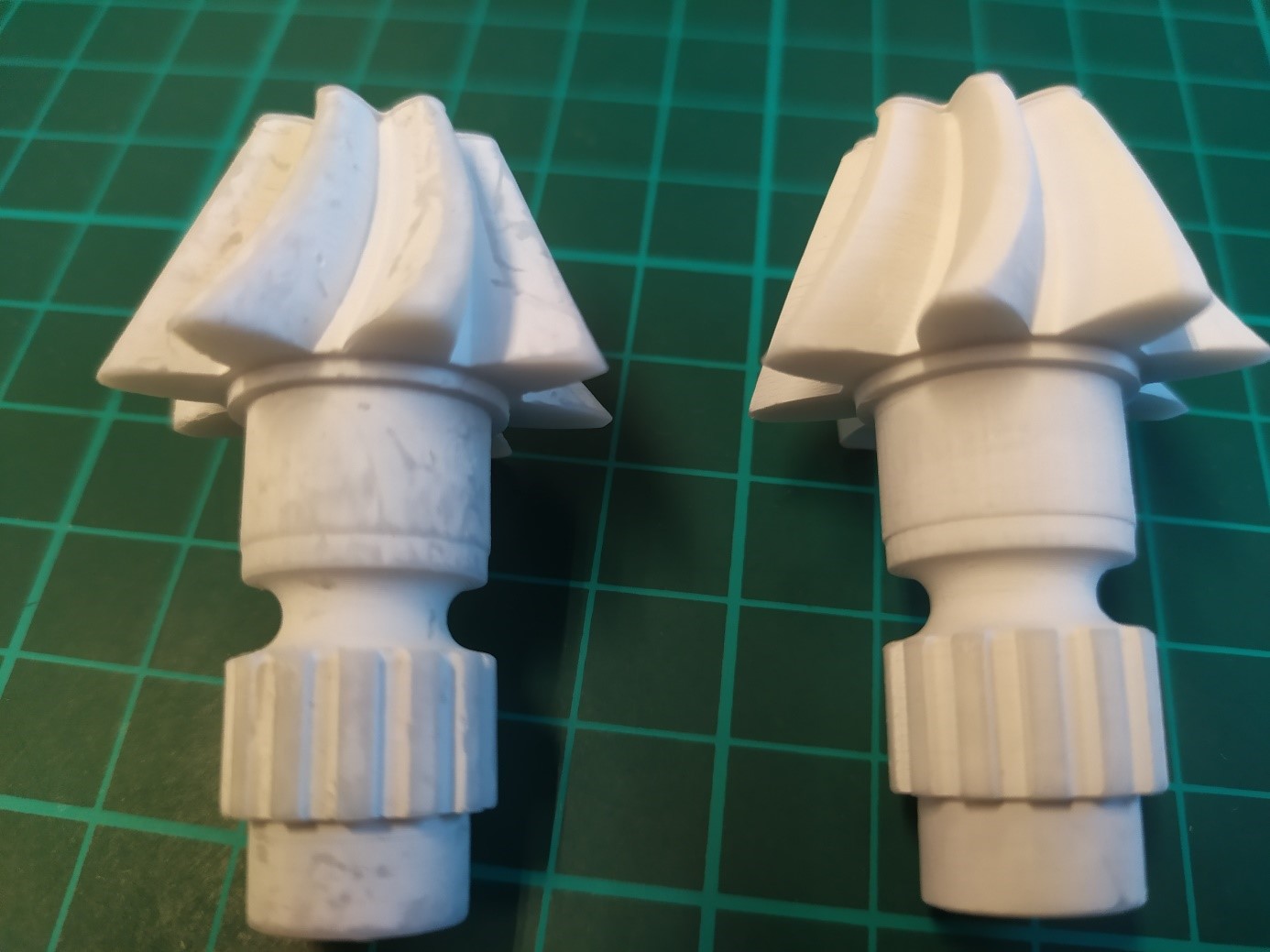

Composite-X is a mixture of ceramic particles with resin. If you wash the parts in an ultrasonic cleaner, the particles on the surface of the composite resins will fall out and holes are present. It is therefore advised to not use ultrasonic cleaner with Composite-X parts, but wash in a agitation device like the Formlabs Wash or Anycubic Washer. On the picture below on the left side is a part washed in an ultrasonic cleaner and right in a Formlabs Wash unit.

Why is the surface of my 3D-print composite part chalky and how to avoid this?

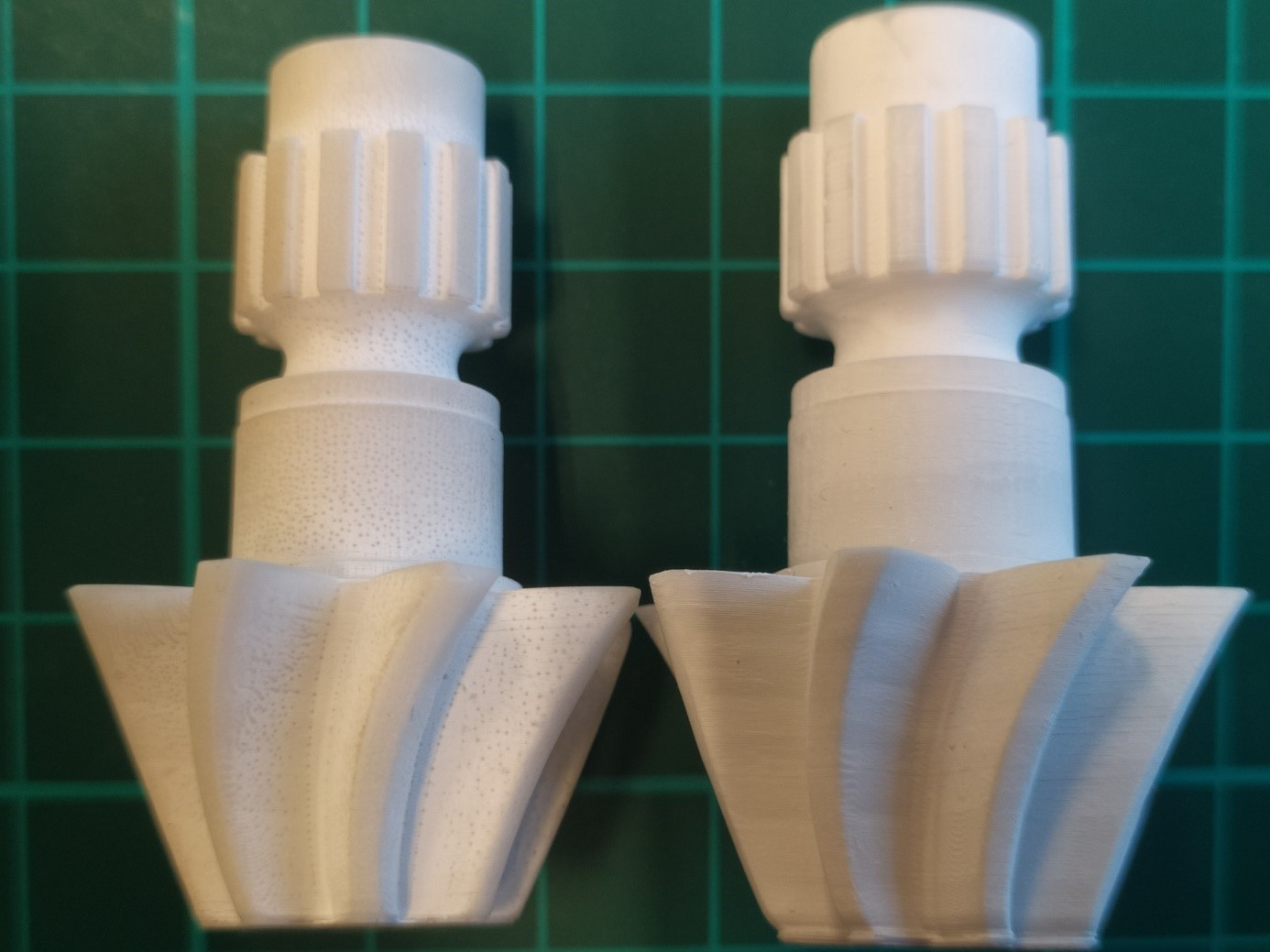

Post-processing Composite-X will take a bit more effort compared to standard resins. If you post-process parts similar to regular resins, the surface of the part can be chalky, see part on in the picture below on the left. The white chalky layer on top of the part can be scratched off the 3D-print composite part easily. This white layer is actually ceramic powder that is responsible for the great properties of composite resins. To get rid of the chalky composite layer, a different washing protocol should be followed. Learn more about it below.

How to wash and post-process parts made of composite resins?

There are a few steps crucial during post-processing of Composite-X. The parts should be washed in an IPA, Ethanol or Resin Cleaner bath, without ultrasonic. To get rid of the chalky composite surface, soak the 3D-print parts in the solvent for 1 minute and scrub the surface with a soft brush. Repeat this step three times and perform a final soak in fresh solvent. Take out the part, let it dry and UV/thermal post-cure according to the settings in this article.

Print is stuck on my platform, how to take it off?

3D-print parts can be severely stuck to the platform if the part is not removed within a few hours after a print job is finished. If this happens, the best way to remove it is by a sharp flat knife. Put it flat in between the part and the platform and try to loosen a corner. Then put some force on it to take the whole part off. Always cut away from your body parts to prevent cutting accidents.

I want to pour the composite resin back in the bottle and there is a residue left, what to do?

If you pour composite resins back in the bottle without mixing, there can be a film of ceramic particles on the bottle of the resin tank. This will look like the picture below. Before pouring the resin back, and before every print, mix the resin and the film of ceramic particles on the bottom to a homogeneous mixture. This way the resin can be poured back in the bottle and saved for the next print.

Why does my FEP film look dull after printing with composite resins?

During printing there is constant movement between the resin and the bottom of the resin tank. Due to the rigid and abrasive ceramic particles in the resin, this will turn the FEP a bit dull after printing. The film is still usable and we have not seen any negative effects on this on print times of other resins, or the Composite-X resin yet.

Why is there a semi-solid film on the top of my platform after printing a long job?

On some platforms, resin will stay on top of the platform. After a long job, or leaving the prints overnight is can happen that the liquid film turns solid. Some of the liquid rein will drip down easier,

leaving a thick film behind. It is advised to take this film off the platform and discard it. Do not mix it back in the resin. There is a high chance that these ceramic particles do not dispense well in the resin, creating weak spots in the final parts.

Some final tips and tricks before printing composite resins!

Hope you share the same enthusiasm to work with this resin as the Liqcreate engineers. There are some final tips and tricks to get the best parts when working with this resin.

- Shake bottle well before using

- Wait 5 minutes to let the air get out before you start the print job

- Mix the resin with a soft/plastic spatula in between every print job and before pouring the resin back in the bottle.

Team Liqcreate wish you happy printing. If there are any questions or remarks, feel free to contact us at info@liqcreate.com any time.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!