Since the beginning of resin 3D-printing, resin engineers are working with jargon like Ec, Dp, cure depth, lambert beer’s law and more. Even if you read back from the “Fundamentals of stereolithography” by Dr. Paul F. Jacobs, Director of R&D 3D-systems published in 1992, they are talking about these values. In this article we try to explain in depth how this works, what these values mean and what you can do with it as an user or engineer. For the short version, this article on our Liqcreate webpage can be of interest.

The curing basics of resin 3D-printing explained

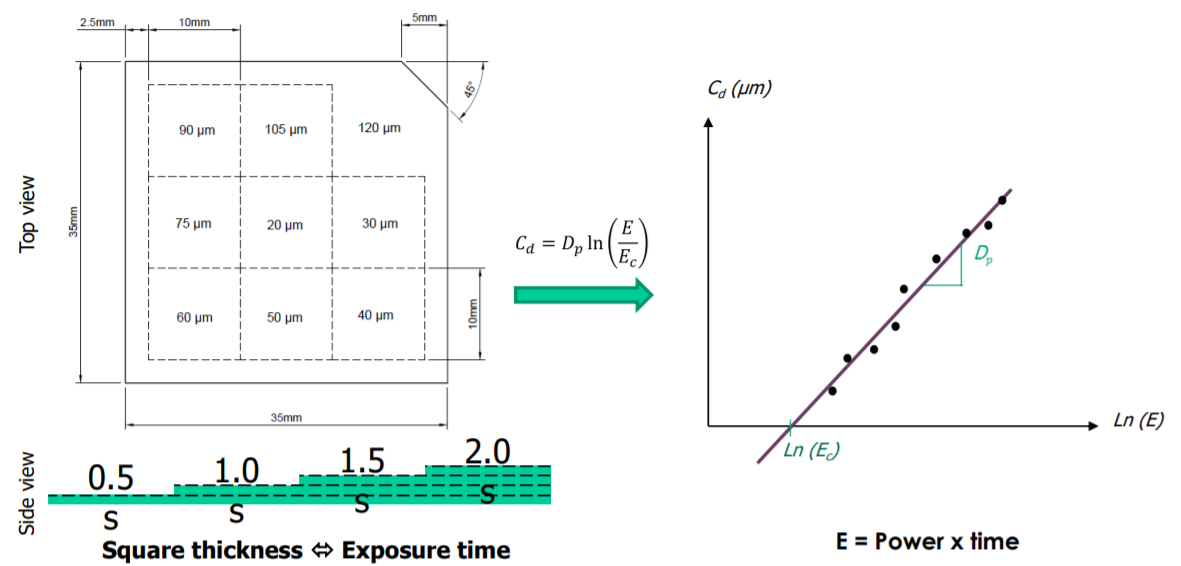

All resins for 3D-printing are photocurable materials, which means that they are reactive to light (with the right wavelength). This reactivity controls how the resins behaves on a specific wavelength. Parameters about its reactivity are the Critical Enegergy (Ec) and the Depth of penetration (Dp), two values which can be found for all Liqcreate materials in their corresponding Technical Data Sheet. These two values are empirically derived values based on measurements mostly using a 405nm DLP 3D-printer. Reactivity to light is measured by exposing the resins with different doses of energy (exposure), in most cases this is controlled by increasing the exposure time in the 3D-printer. The layer thickness of the cured resin is measured and plotted versus the corresponding energy input as seen in the figure below. Giving an Ec and Dp value.

The photoinitiator that is solved in the resin will absorb the light (at the right wavelength) and is using the energy to start the reaction. The cure depth will always be finite, leading to a logarithmic correlation between the exposure and the cure depth, a typical curve is shown in the figure above. This is derived from the Lambert Beer law which describes the relationship between the concentration and the absorbance of the solution. In this case the resin is the solution.[10]

When plotting the working curve (thickness in micrometers vs light energy) it is a visual representation of the correlation between printer and resin. Based on this a mathematical correlation is derived, as shown in formula 1 with:

Cd = Cure Depth [mm] (layer thickness)

Dp = Depth of penetration [mm] (slope of Cd vs LogExp)

Ec = Critical Energy [J/mm2] (the minimal amount of energy required to form a solid layer)

Cd = Dp • In(Exp) + Ec

And where Exp = exposure [J/m2 or mJ/cm2], which is a function of the exposure time calculated as shown in formula 2, with:

t = Time [s] (illumination time)

Irr = Irradiance [W/m2] (power of the lightsource)

Exp = t • Irr

How do these parameter describe the behavior of resins in a 3D-printer from a more practical point of view? Well, the depth of penetration (Dp) shows a materials sensitivity to changes in light output, which means that a material with a lower Dp has better performance when subjected to variations in exposure time/light source power, while a material with a higher Dp, is more likely a faster printing material but also more sensitive for failure at deviations in light output. Whereas its seems that a faster printing resins is more preferable, a less sensitive resins is practice more useful, because of high likeliness in changes in light output due to lack of proper cleaning and degradation of the light source.

The critical energy (Ec) is a value for the minimum amount of energy required to form a solid layer and therefor the minimum amount of energy required for 3D-printing. These values are derived from practical measurements, which means that they can vary when the parameters within the measurement are changed like temperature and wavelength. Last value that can be taken from this graph is the maximum cure depth (max Cd) of a material. This is the practical maximum thickness that you can cure a resin. This is important when you have to over-come the first layer gap in a 3D-printer which can be several hundred microns.

Curing behavior of resin 3D-printing in practice

That was all theoretical, lets see how this works in practice. We have taken our commercial Premium Black resin and ran it on two different DLP machines that are open for these type of tests. One is the Asiga Max (DLP, 385nm) which was set at 8mW/cm2 and 4mW/cm2 power and has a 385nm light source and the other one an open 405nm DLP with 8mW/cm2 power.

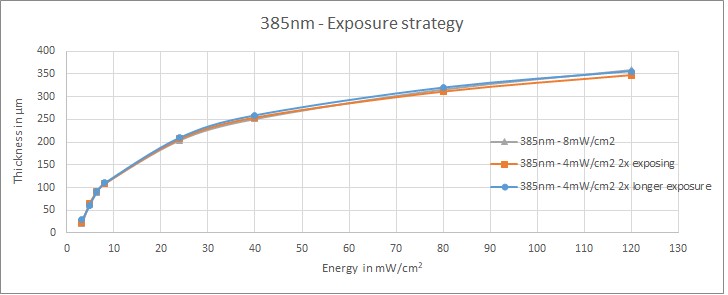

Three different sets were measured on the 385nm Asiga at 8 and 4mW/cm2 with Premium Black resin. First Premium Black was measured at 8mW/cm2 and exposed with different timing / power. Afterwards the power was set to 4mW/cm2 and two more sets were measured, one with 2x exposure (so same total energy) and one with were the 2x exposure was given in two different bursts. If you plot the data in thickness (in micrometers) vs energy (in mW/cm2) these results were obtained.

This validates that within the experiment window, the resin behaves according to Lambert Beers law and a different exposure strategy does not change it absorption or curing mechanism significantly.

405nm vs 385nm wavelength

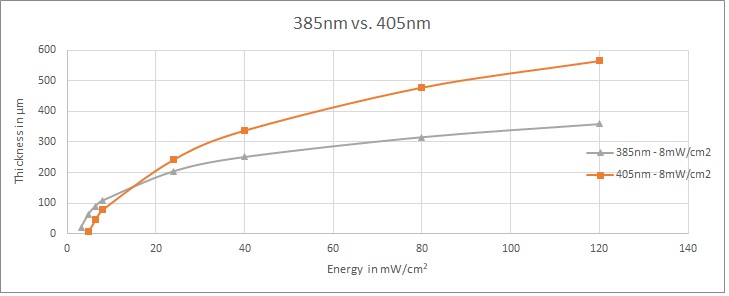

Then doing the same experiment with Premium Black at 405nm and 385nm (both 8mW/cm2) power, you can see big differences as the resin behaves different with different wavelengths.

Three things you can learn from the tests on this specific resin:

- – 385nm is more efficient with the start of curing (lower Ec)

- – 405nm is more efficient in curing thick layers (higher Dp)

- – The slope of the 405nm test is steeper, making it more susceptible for through-cure but also can increase print speed at thicker layers.

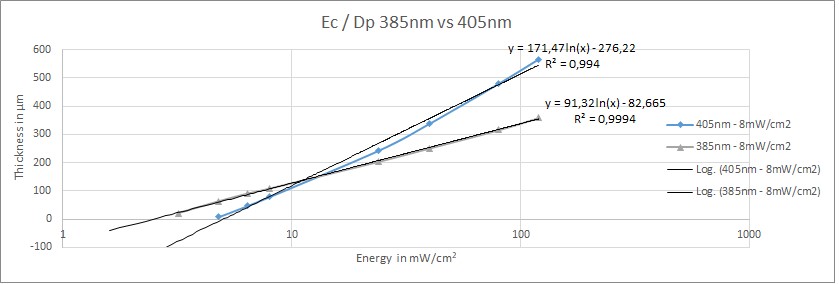

Ec and Dp for 405nm vs 385nm wavelength

As you can see from the previous graph, the Ec and Dp values are also different for 385nm and 405nm. When nothing is stated, best is to ask the manufacturer on which wavelength the Ec and Dp is measured. Standard we do this at 405nm, but also intend to expand this to 385nm.

Calculating both Ec and Dp of Premium Black at 405nm and 385nm would give the following values:

| 405nm | 385nm | |

| Ec | 5,00 mJ/cm2 | 2,47 mJ/cm2 |

| Dp | 0,1714 mm | 0,0932 mm |

| Cure depth | ~ 0,60 mm | ~ 0,40 mm |

We hope this was an interesting and educational read. If you have any questions or comments about this subject or other resin related things, please send us an e-mail at info@liqcreate.com and our engineers will help.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Printer Settings →

About Liqcreate Premium Black

Liqcreate Premium Black is an opaque black photopolymer resin with excellent color stability, ideal for rapid prototyping and concept product development. 3D-printed parts from this material have exceptional dimensional stability and low shrinkage during printing. Liqcreate Premium Black is easy to use on all open source MSLA/LCD and DLP 3D-printers in the range of 385 – 420nm. This material has excellent properties like low shrinkage and low odor, which makes it ideal for applications that require an opaque, deep black surface finish.

Key benefits

|

3D-Printer compatibility |

| · Opaque Black | · Asiga Max & Pro 4K |

| · Compatible with 2K, 4K & 8K printers | · Shininig3D Accufab-L4K |

| · Low odor | · Elegoo & Creality Series |

| · Low shrinkage | · Anycubic & Phrozen Series |

| · High reactivity | · And many more |