When a liquid 3D-printing resin is exposed by light with the right wavelength and power, the material starts to react and form a link between the monomers. When a monomer chain is long enough, it will turn into a gel or even a solid part. With resin 3D-printing you will not get a fully cured resin from the 3D-printer, so you need to post-cure it after printing. This last post-curing step is important to push the resin to a high polymerization grade and get its final properties. Additionally if you don’t cure it properly, the resin will cure on your desk and properties will change over time. Post-curing is therefore very important for engineering parts, you can read our study on post-curing vs. mechanical properties here. Several post-curing units, from entry-level to professional are tested and benchmarked.

Can resin properties change with longer exposure time during 3D-printing?

With a lot of materials we would instantly say that post-curing is much more important for final properties then exposure time during printing. The only importance during printing is that the part is printed without any defects. Defects can lead to early failure in parts. With a tough R&D resin we have performed some tests to show that there are some boundaries to this theory.

Tested the mechanical properties of a tough resin with longer exposure time during 3D-printing

For a new development we are tested a R&D tough formulation (black color) and printed it at different exposure times. It was determined that the ideal exposure time of this resin was 8,0 seconds at 0,1mm layer thickness on the Anycubic Photon Mono. Lower exposure times lead to fails and were not tested as this will give inferior properties anyway. Parts were washed 2x in IPA for 2 minutes, bench-dried for a day and then post-cured for 30 minutes at 60C in the Wicked Engineering Curebox.

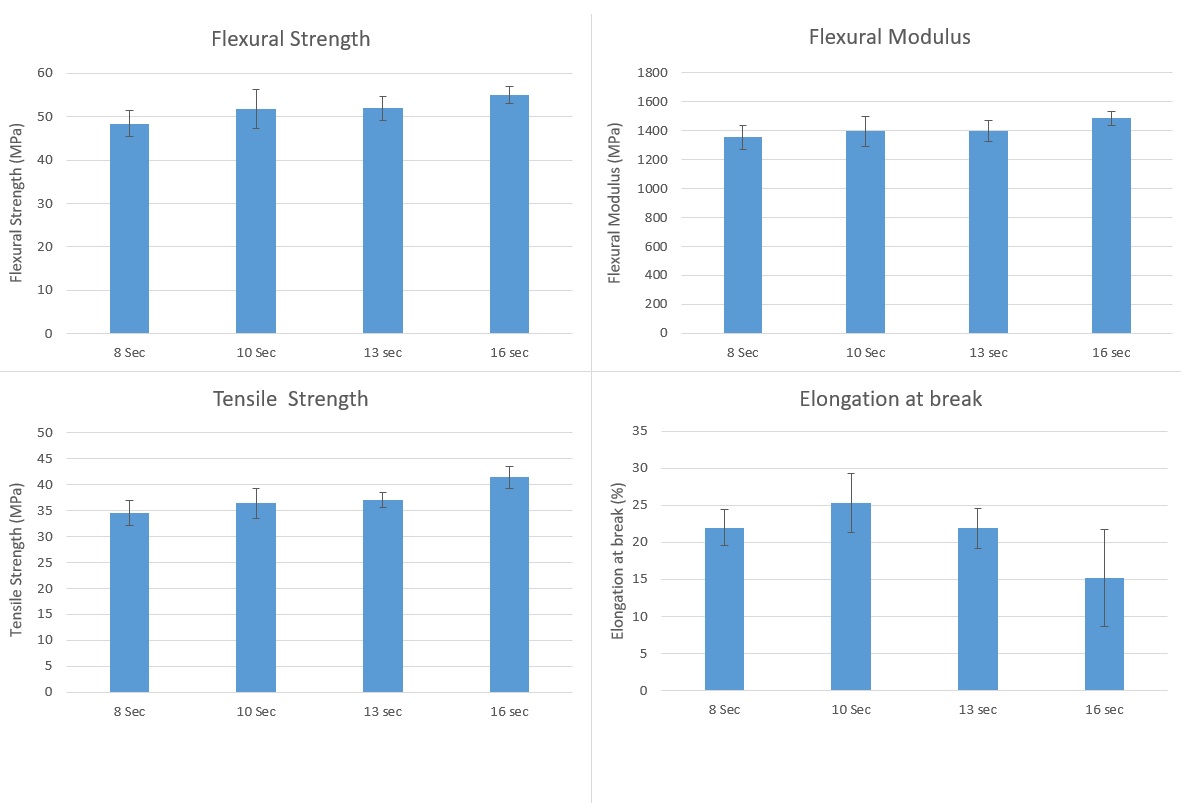

What you can see from the results is that with slight over-exposure of the parts, a minimal increase is seen in properties. A process window of 8-13 seconds will give good results. When doubling exposure time from 8 to 16 seconds per layer will give a more rigid material, with lower modulus and scattered results. So within the process window of a few seconds stable and good results can be obtained.

It should be noted that this can be different per resin and post-curing unit. But these results can serve as a general guideline for tough resins. Hope this was an interesting and educational read. If you have any questions or comments, feel free to reach out to info@liqcreate.com.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!