Liqcreate would like to thank the guest writers at 43dprint.org for writing an article on our website. If you’re in the market for a 3D printer, you’ve probably realized that there are two different options when it comes to 3D printer technology: filament and resin. Chances are that you’re wondering which one is best.

Well, the unfortunate fact is that there’s no short answer to this question. Both technologies come with their own pros and cons and, despite both being capable of printing a seemingly endless number of unique creations and handy objects, they are different in many ways.

Today, we’re going to help you get to the bottom of what makes each type of 3D printer unique so that you can make an informed decision when it comes time to commit.

Differences Between Resin and Filament 3D Printers

Cost

When you’re scoping out a new 3D printer, it’s not just about the price tag on the printer itself — you also have to take into consideration the cost of the filament or resin your chosen printer uses, other accessories, and time.

In terms of upfront cost, FDM printers (filament) generally come out on top. This is especially true for 3D printing novices, as entry-level, budget-friendly SLA/DLP printers (resin) are a rare find.

In addition, the upkeep of your printer is another cost to keep in mind. For filament printers, a spool of filament is usually under $30 and maintenance – such as nozzle replacement- is infrequent.

In resin printers, however, both the resin and resin tanks must be replaced frequently. Tanks cost around $40, and a liter of resin can cost upwards of $80, which makes frequent maintenance and proper upkeep a bit of a financial commitment.

Quality

Perhaps one of the most important things to think about when comparing the differences between the two types of 3D printers is the quality of printed objects that are produced by each.

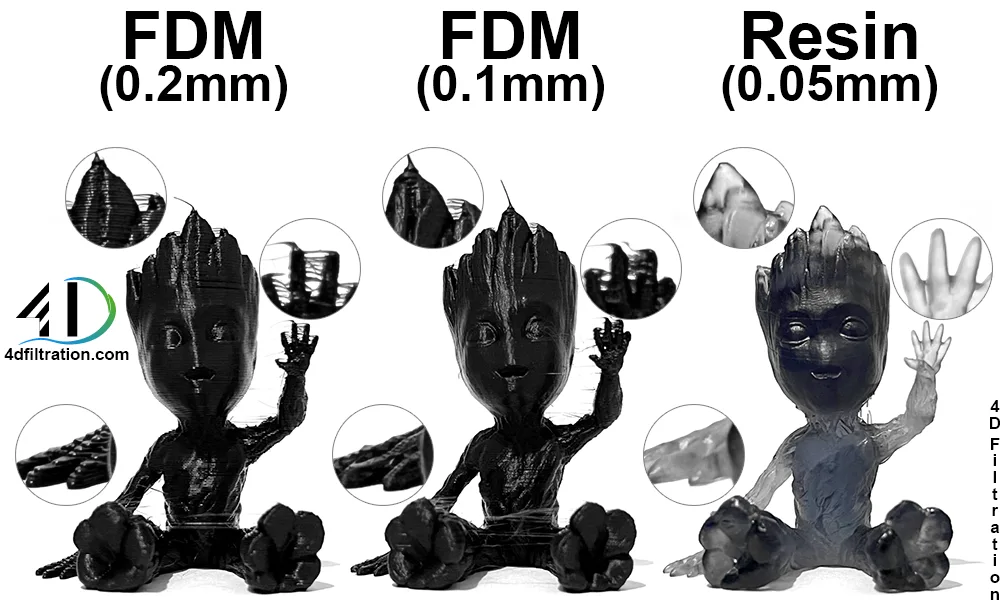

Filament printers use several factors such as nozzle size, extruder precision, and layer adhesion to print their pieces. This often results in shifting, warping, and shrinkage. These issues can usually be remedied with a bit of time and patience post-processing.

Resin printers generally offer a higher quality final product, as they use a laser to determine and key in fine details, which leads to spectacular accuracy and a high level of detail.

Image by 4Dfiltration: resin vs filament quality in 3D-printing.

General Ease of Use

Whether you opt to go for a resin or filament 3D printer, there’s going to be a learning curve when it’s your first time behind the wheel.

If you choose a filament printer, you’ll need to manually remove the print from the machine’s print bed with a palette knife and perform post-processing in the form of snipping off excess plastic and sanding. These tasks are fairly simple and straightforward.

With resin printers, it can be a bit more difficult to remove the final print, as there is often a lot of excess resin leftover that needs to be dealt with. Objects that come out of the printer need to be wiped with isopropyl alcohol and may even need to be placed in a UV oven to complete the processing process. Like the post-processing of filament prints, these tasks are also easy– but they take a bit longer and require some additional supplies.

Strength of Printed Pieces

Filament printers come in first place when it comes to the strength of 3D printer pieces. In general, filament prints have higher tensile strength, do not decay as quickly after exposure to the environment, and sustain better impact loads.

Pieces produced on resin printers are hard and brittle, and are known for breaking away under impact loads. The resin used in resin printers is sensitive to UV light, so pieces that are kept in the sun may lose their color and become more brittle as time goes on. Special or engineering resins are designed to be less brittle.

Printing Speed

Filament printers produce single objects much faster than resin printers. By adding more objects to the print bed, the time that printing takes will increase, as expected. This is because the nozzle traces each part individually.

Resin printers can produce more than one object just about as fast as it would a single object. This is because the LCD is exposed to the individual layers for a fixed amount of time, regardless of how many things are being printed. Resin tends to be a lot faster in instances where you’re trying to print a plethora of objects at once.

Assembly

While all 3D printers require some level of assembly, filament printers require the most — and even so, the amount that each one requires will vary. Some arrive mostly pre-assembled, while others must be put together from the ground up. Those that are partly assembled before leaving the manufacturer can take anywhere from 10-30 minutes, with those on the other end of the spectrum taking up to an hour.

Due to the smaller size of resin printers, they take a lot less time to assemble. Many of them come almost fully assembled.

Software Setup

After assembly, it’s time to set up your printer’s software.

Filament printers take some time to set up, as you must learn all the different settings and what each one does before completing the setup process. Adjustments are needed often, so it’s crucial to learn these things before attempting to use your 3D printer. Mastering the settings can take quite a bit of time, as it’s necessary to experiment, adjust, and repeat.

Resin printers are simpler, including fewer settings to learn and configure. Most users will only ever have to adjust two settings: layer time and the settings for support material. Print orientation is another good setting to learn.

Conclusion

Now that you know some of the major differences between resin and filament 3D printers, you’ll be able to make a smart choice based on your needs, budget, and desires. There is a great selection of both types of printers to choose from, many of which are, unfortunately, quite the monetary investment.

But if you’re looking to purchase one of the best 3D printers under $500, you’ve still got plenty of great options.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!