3D-Printed parts are used in a wide range of applications. In some of these applications the parts are exposed to petrol, cleaning agents or other chemicals. Our engineering team started to investigate the resistance of common chemicals on 3D-printed parts. Compatibility of 3D-printed and post-cured resin parts were tested with several chemicals in this article and some other articles can be found here:

Chemical compatibility of 3D-printing resin with automotive fluids.

Chemical compatibility of 3D-printing resin with acetone.

Chemical compatibility of 3D-printing resin with (chlorinated) swimming pool water.

In the first test, the weight of the 3D-printed resin parts were tested after 24 hours immersion in a chemical solution. Followed by a test were the mechanical properties of 3D-printed resin specimen were measured after 7 days of immersion in chemical several solutions.

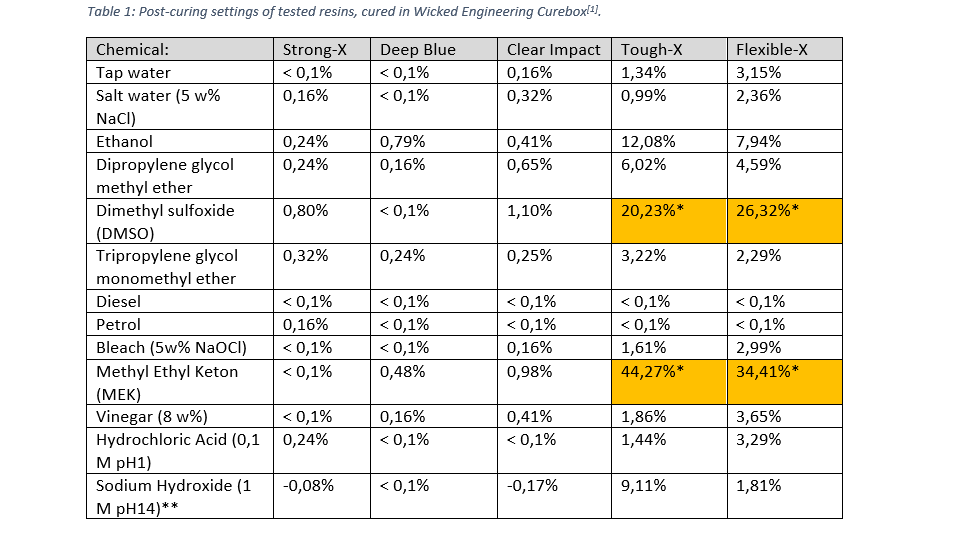

Weigth gain of 3D-printed resin parts after 1 day immersion in chemical solutions.

Weight gain of each resin tested after 24 hour immersion can be found below.

*Materials in orange fields showed cracks or lost pieces during 24 hour soaking of during drying.

** All resins immersed in sodium hydroxide had a soft outer surface. Negative values could indicate potential dissolving or degradation of the resin.

How was the weight gain of the 3D-printed materials immersed in chemicals tested?

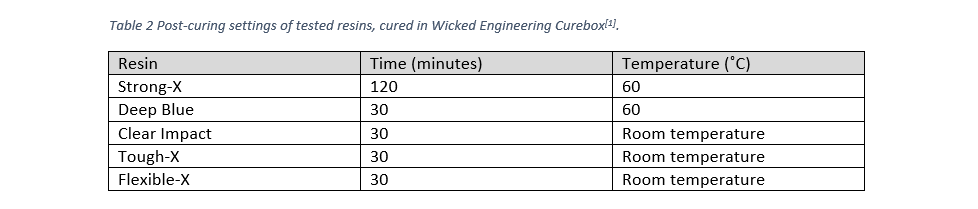

Compatibility of post-cured 3D-printed resin parts were tested with several chemicals. From five resins, blocks of 20 x 20 x 20 mm were printed, washed in Liqcreate Resin Cleaner and post-cured according to the table below. The weight of the blocks was measured before the test and after 24 hour immersion in the specific chemical solution. The surface of the immersed blocks was wiped dry before weighing.

Compatibility was tested with the following cleaning materials, industrial liquids and household chemicals:

– Tap water

– Salt water (5 w% NaCl)

– Ethanol

– Dipropylene glycol methyl ether

– Dimethyl sulfoxide (DMSO)

– Tripropylene glycol monomethyl ether

– Diesel

– Petrol

– Bleach (5w% NaOCl)

– Methyl Ethyl Keton (MEK)

– Vinegar (8 w%)

– Hydrocholic Acid (0,1 M pH1)

– Sodium Hydroxide (1 M pH14)

Mechanical properties of 3D-printed resin part after 7 days immersion in chemical solution

Mechanical properties of Liqcreate engineering resins and Deep Blue 3d-printing resin were tested after 7 days immersion in chemical solutions. Test samples were printed in Z-direction and washed and post-cured according to the product recommendations. Detailed explanation of the measured properties can be found in this article.

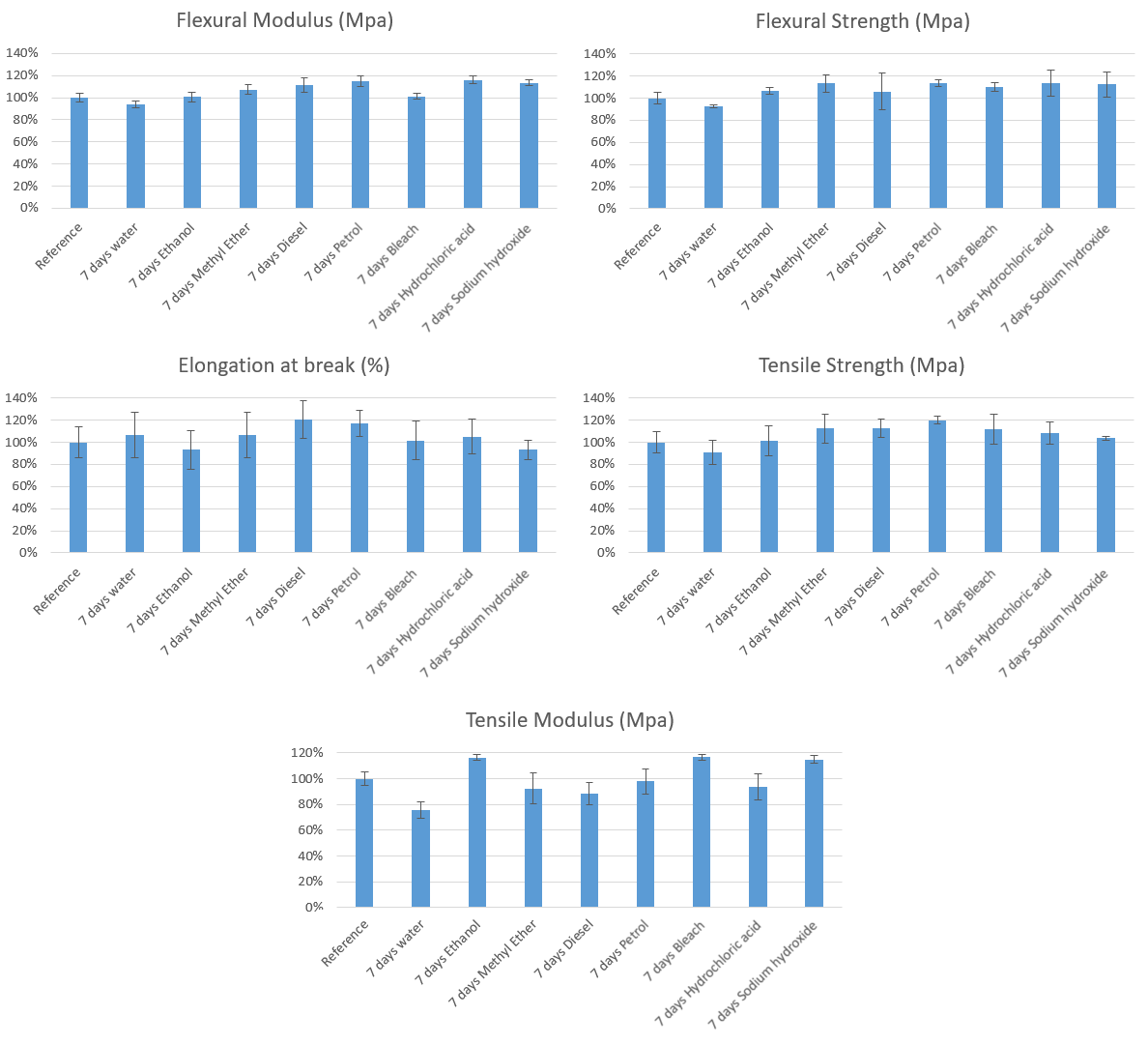

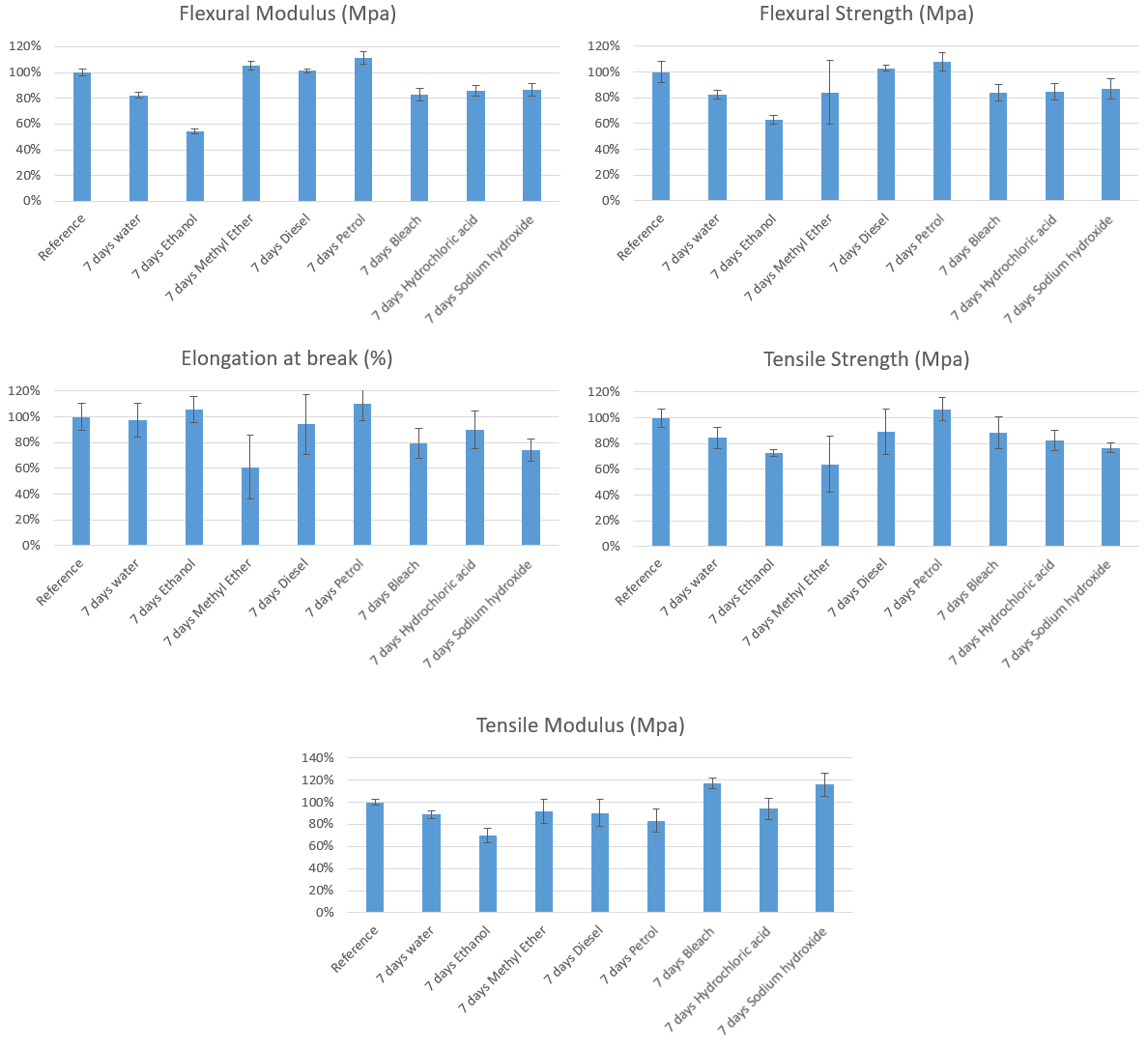

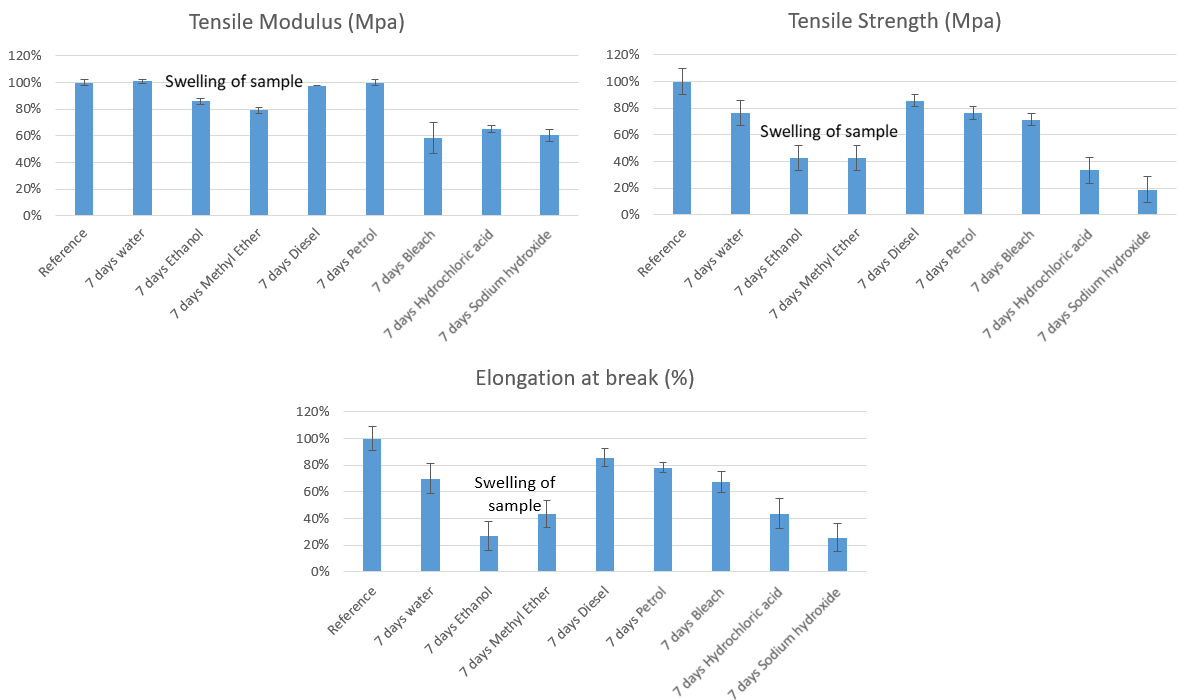

Chemical compatibility of Deep Blue 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Deep Blue resin can be found below.

As seen in the results above, Liqcreate Deep Blue 3D-printing resin is resistant to all tested chemical solutions. The highest deviation from the test group was found in the tensile modulus after 7 days immersion in water, which shows a drop of just over 20%. most other results are very similar to the reference measurement.

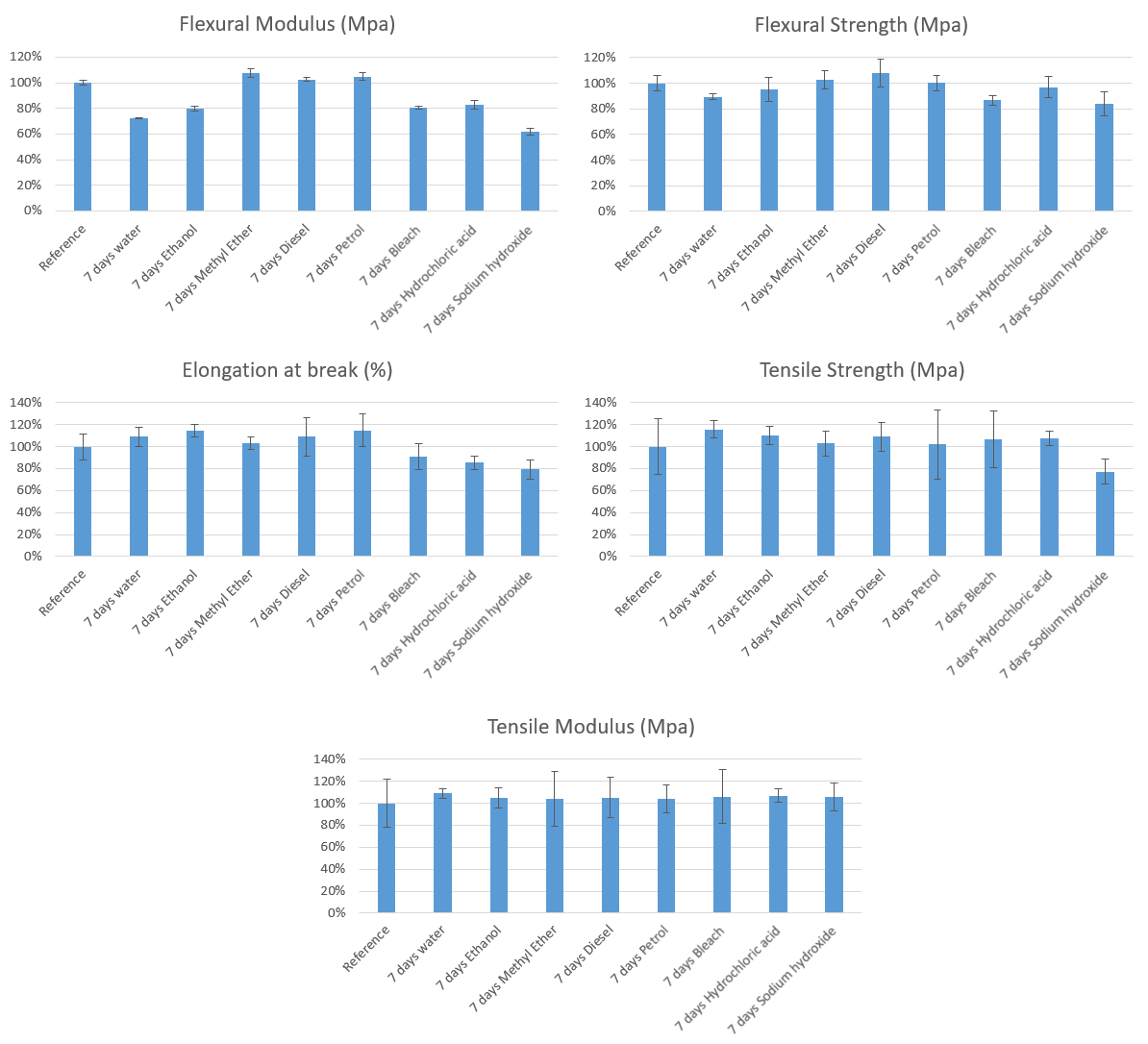

Chemical compatibility of Strong-X 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Strong-X resin can be found below.

For most chemical solutions, Strong-X performs similar to Deep Blue. However, Strong-X is more sensitive in ethanol and methyl ether solutions. Critical parts that come in contact with these chemical solutions are advised to be 3D-printed in Deep Blue resin.

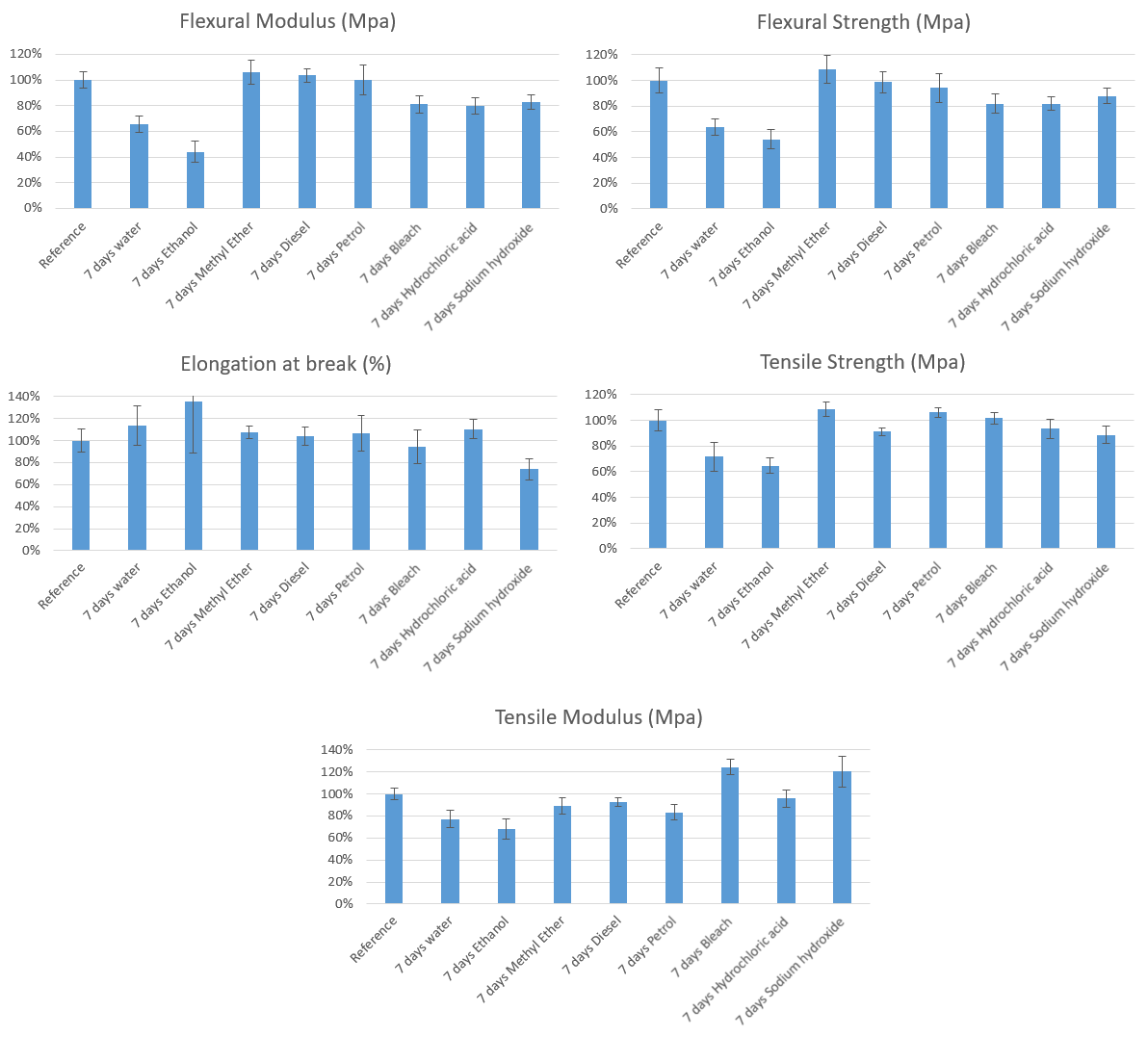

Chemical compatibility of Composite-X 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Composite-X resin can be found below.

Composite-X shows great performance in most chemical solutions. A decrease in performance is seen for sodium hydroxide and water. It should be noted that after a reduction of 40% of its extremely high strength of 140 – 170 MPa, the material still has a high strength.

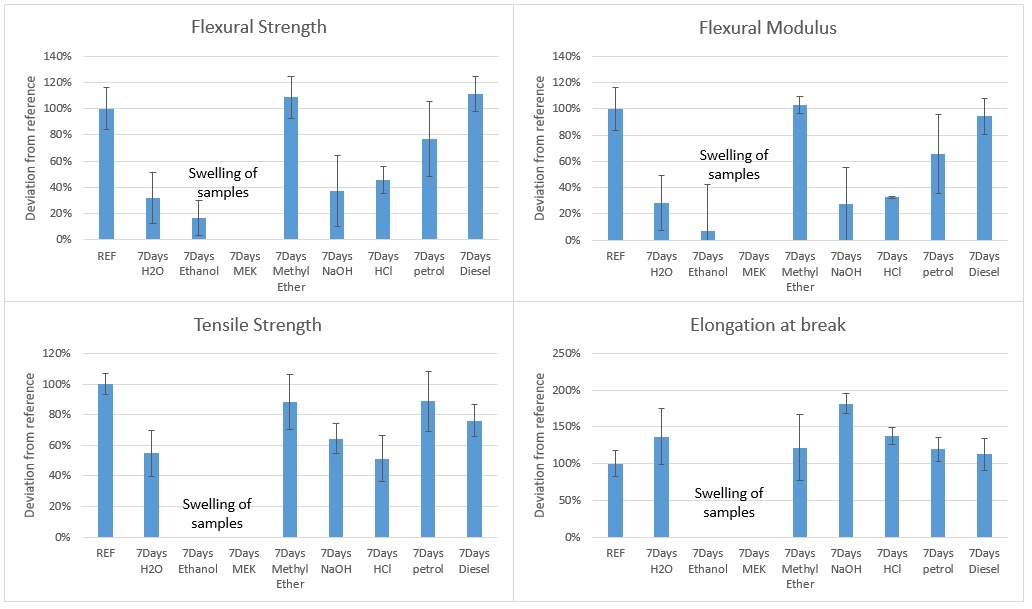

Chemical compatibility of Clear Impact 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Clear Impact resin can be found below.

When a tough material is required for your part that is in contact with chemicals, Clear impact is a good option. However, for Water and Ethanol contact, the reduction in properties might be too much for critical parts.

Chemical compatibility of Tough-X 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Tough-X resin can be found below.

Tough-X is an extremely impact resistant photopolymer resin. Thin parts tend to be bendable while thicker 3D-printed parts are extremely robust. Thin parts mimic hard rubber and are sometimes used as sealants. Most chemicals are too harsh for Tough-X. Oil based chemicals like diesel, fuel and petrol won’t change the mechanical properties of this resin. All other chemical environments should be well considered before using it in a final application. Tough-X parts immersed in Sodium Hydroxide had blisters after 1 week immersion and should therefore not be used in basic solutions.

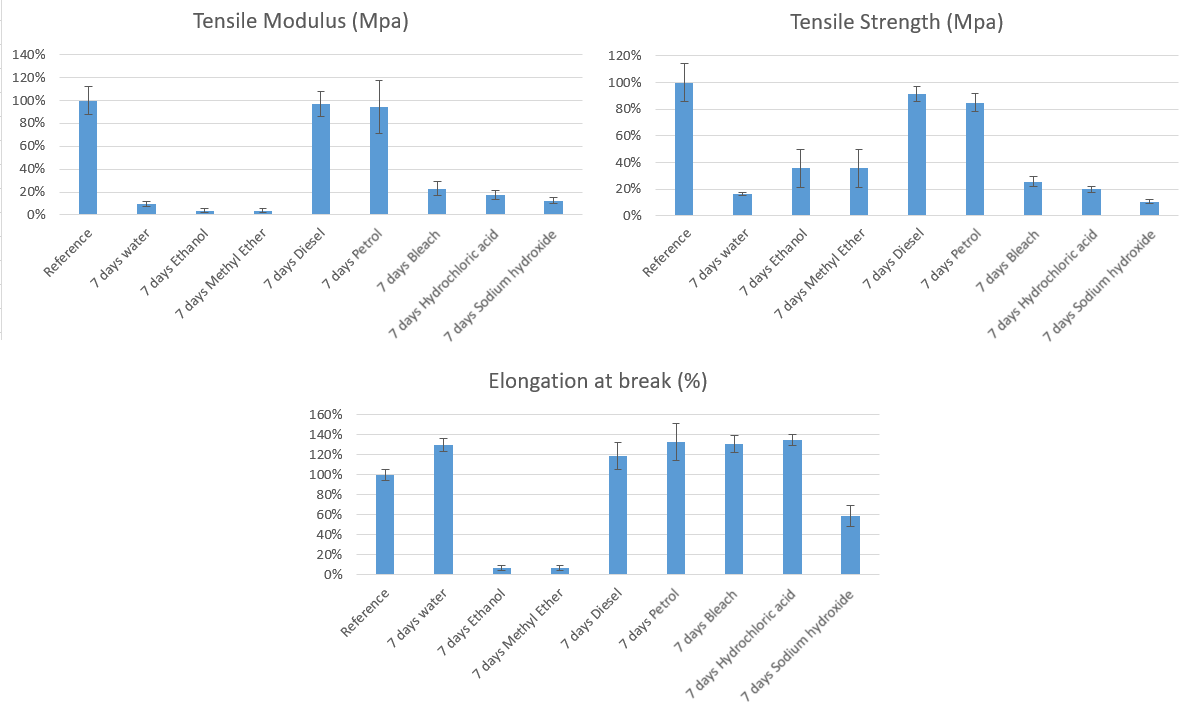

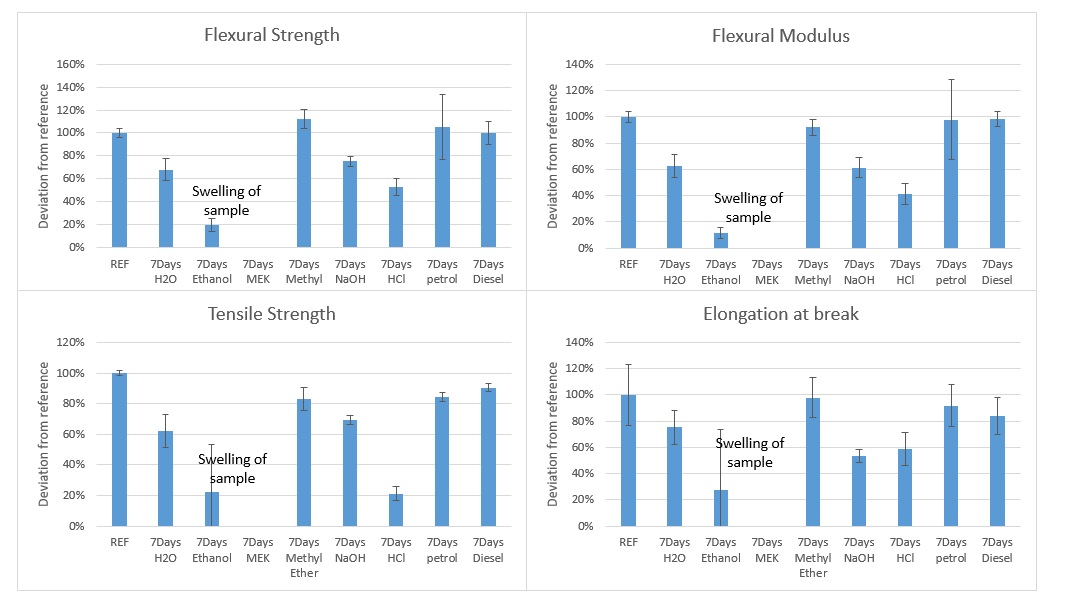

Chemical compatibility of Flexible-X 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Flexible-X resin can be found below.

flexible-X an extremely soft, flexible and elastic elastomer photopolymer resin. Solvents like ethanol, methyl ethers and sodium hydroxide are not compatible with this material. Water, diesel and petrol show still acceptable properties after 7 days immerison.

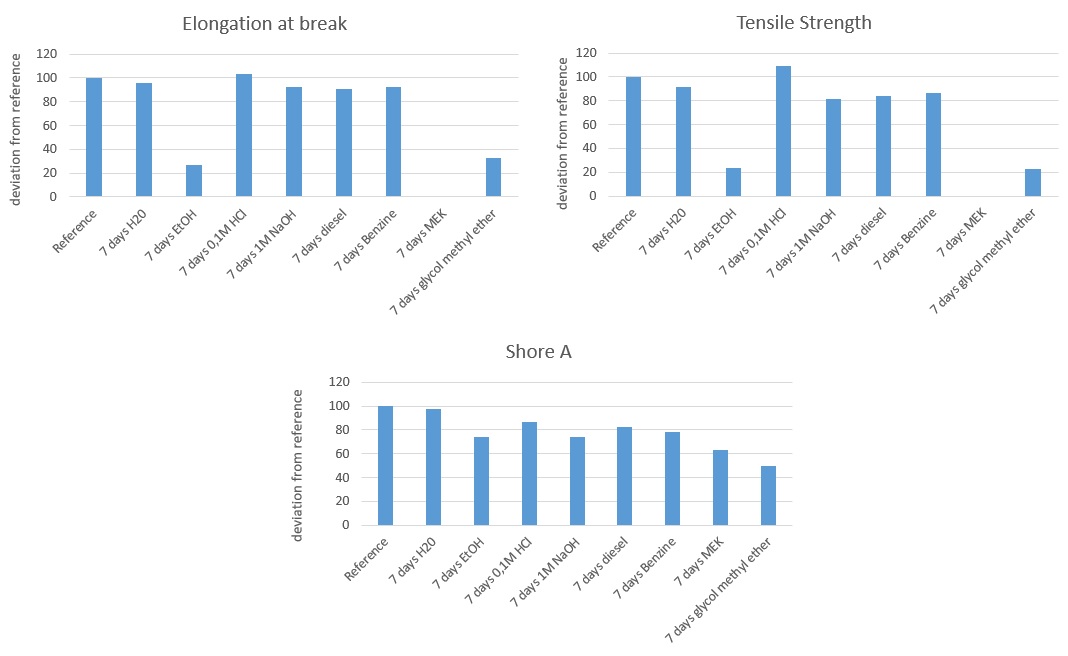

Chemical compatibility of Elastomer-X 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Elastomer-X resin can be found below.

Elastomer-X performs well in most media. Only prolonged exposure to ethanol, MEK and glycol methyl ether or similar chemicals will result in swelling and significant decrease of mechanical properties.

Chemical compatibility of ESD-X 3D-printing resin

Chemical compatibility of 3D-printed test specimen from ESD resin can be found below.

ESD performs well in some media like Petrol, Diesel and Methyl Ether. Prolonged exposure to other media like ethenol, MEK, strong acids and bases are not advised as they can cause a significant decrease in mechanical properties.

ESD performs well in some media like Petrol, Diesel and Methyl Ether. Prolonged exposure to other media like ethenol, MEK, strong acids and bases are not advised as they can cause a significant decrease in mechanical properties.

Chemical compatibility of Bio-Med Clear 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Bio-Med Clear resin can be found below.

Bio-Med Clear performs well in most media. Prolonged exposure MEK and similar aggressive solvents can lead to decrease in properties over time.

Bio-Med Clear performs well in most media. Prolonged exposure MEK and similar aggressive solvents can lead to decrease in properties over time.

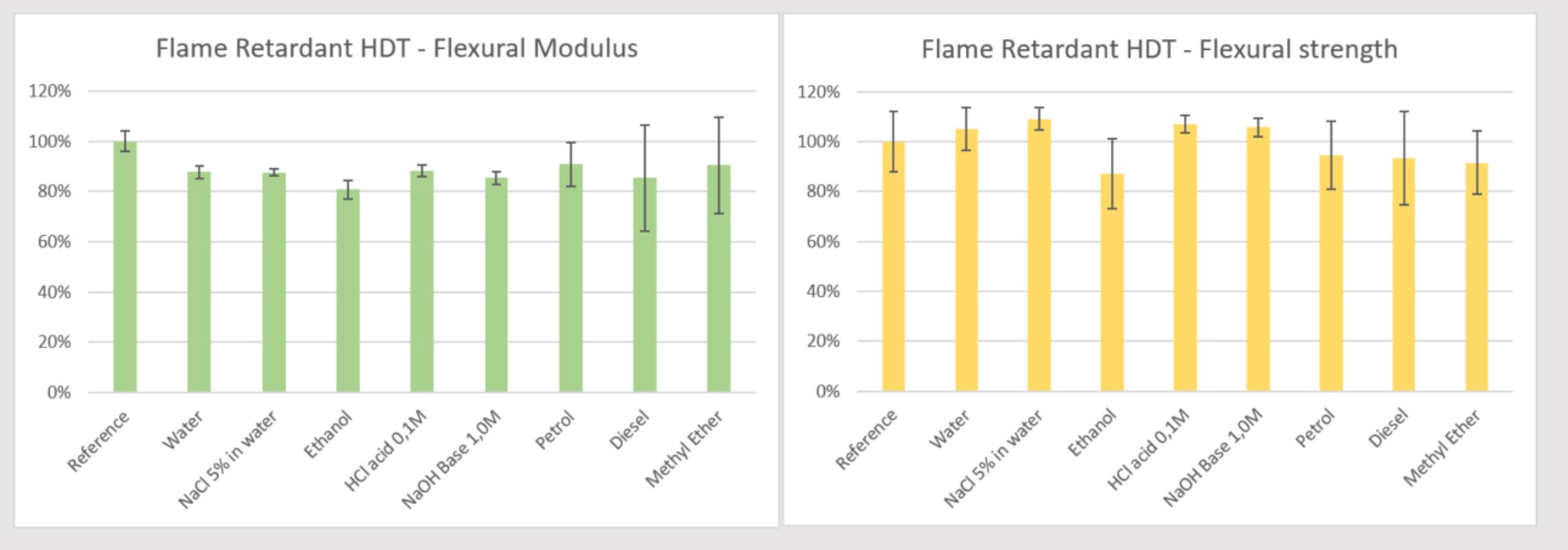

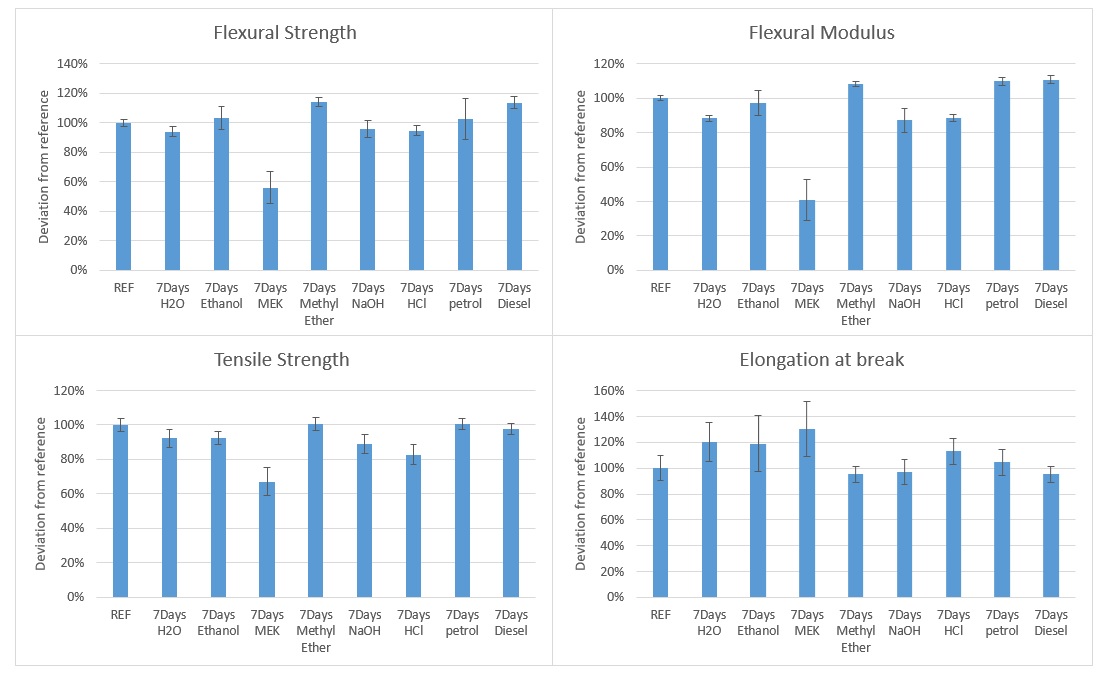

Chemical compatibility of Flame Retardant HDT Clear 3D-printing resin

Chemical compatibility (7 days immersion) of 3D-printed test specimen from Flame retardant HDT resin can be found below.

Most chemicals this resin performs well. Extended periods of ethanol exposure is the only one tested that had a slightly higher drop and standard deviation compared to the reference.

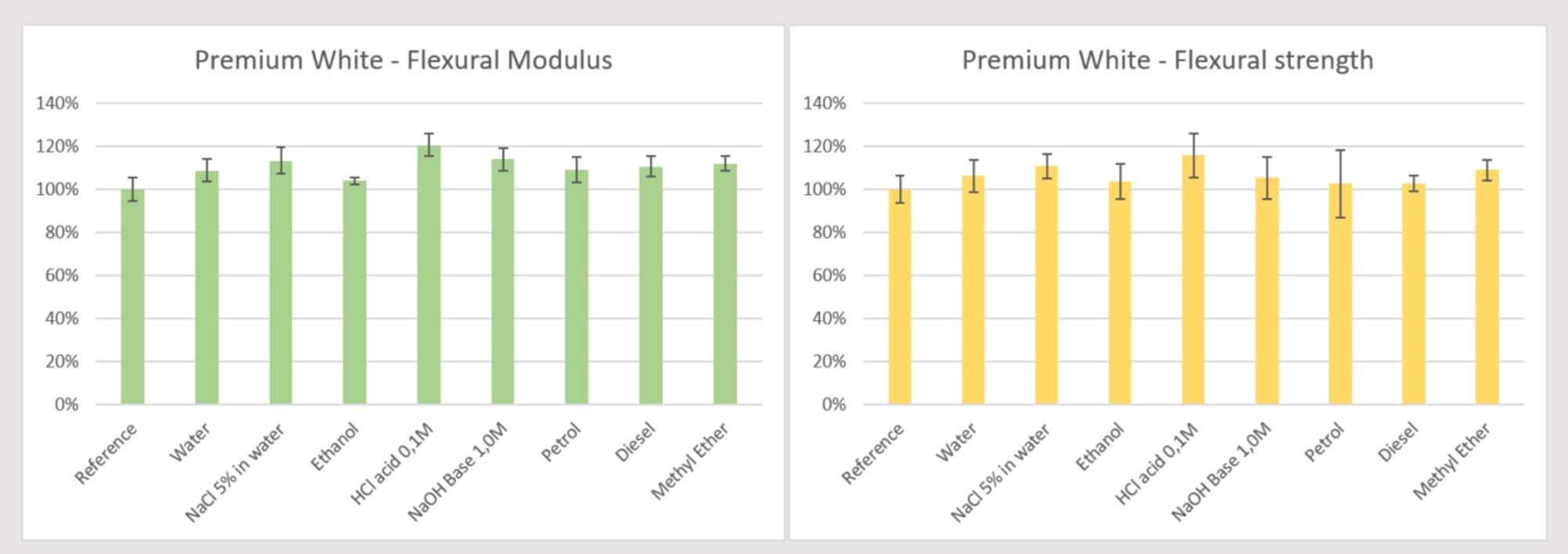

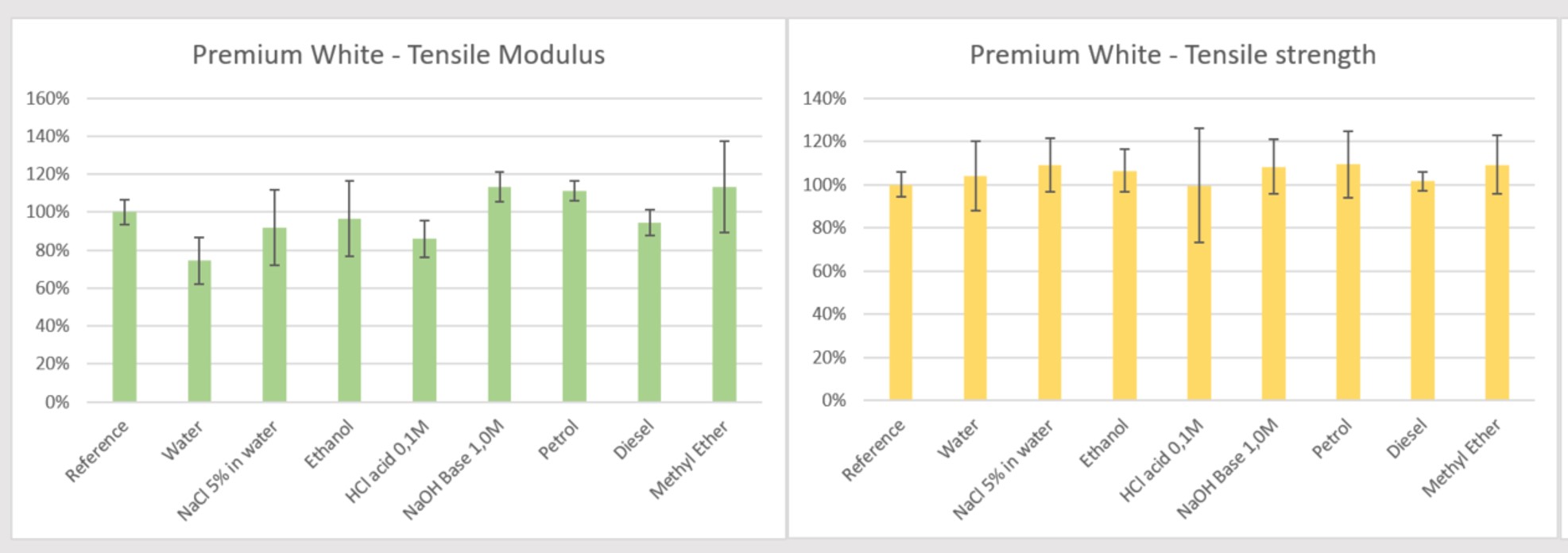

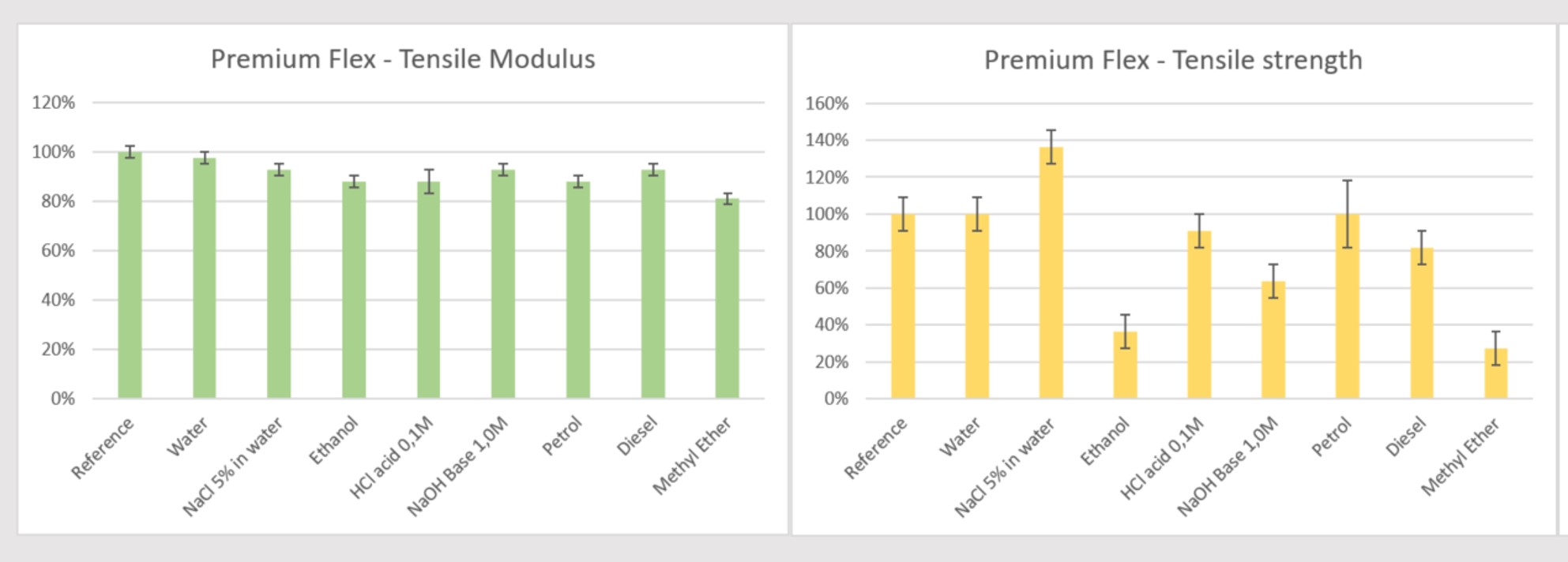

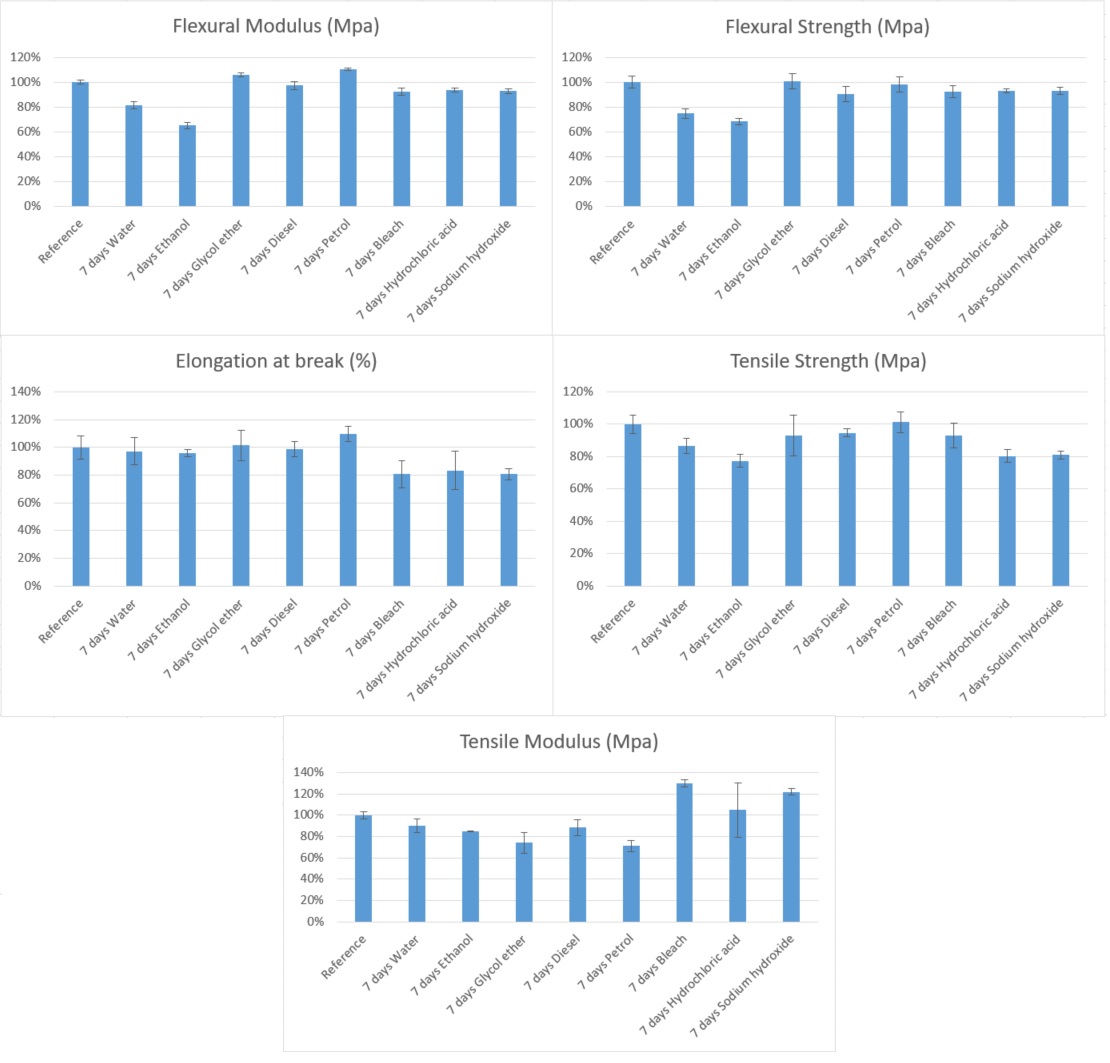

Chemical compatibility of Premium White 3D-printing resin

Chemical compatibility (7 days immerison) of 3D-printed test specimen from Premium White resin can be found below.

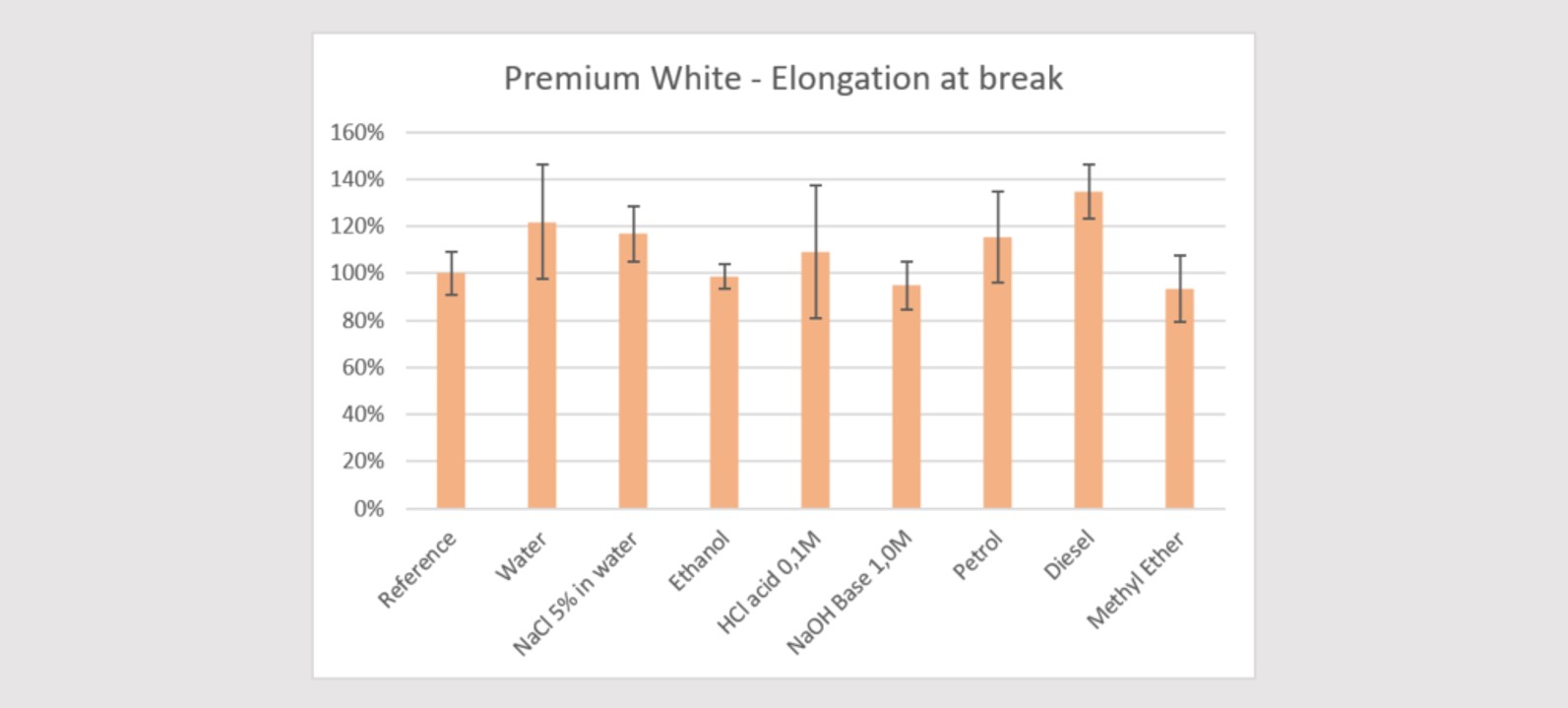

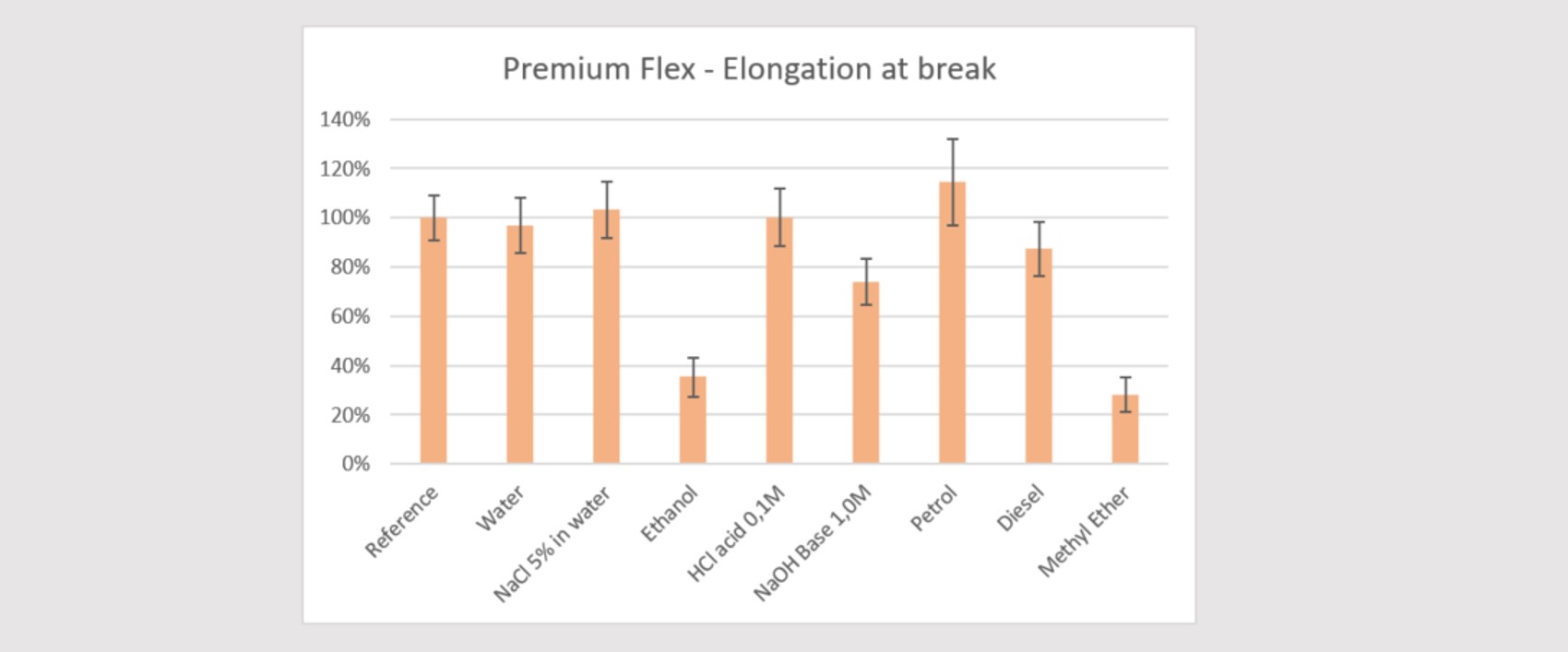

Chemical compatibility of Premium Flex 3D-printing resin

Chemical compatibility (7 days immersion) of 3D-printed test specimen from Premium Flex resin can be found below.

For Premium Flex a few chemicals can be challenging, mainly ethanol, methyl ether and similar materials are not suitable to be used with Premium Flex.

Chemical compatibility of Premium Tough 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Premium Tough resin can be found below.

Premium Tough performs well in some media like Petrol, Diesel and Methyl Ether. Prolonged exposure to other media like Ethenol, MEK, strong acids and bases are not advised as they can cause a significant decrease in mechanical properties..

Premium Tough performs well in some media like Petrol, Diesel and Methyl Ether. Prolonged exposure to other media like Ethenol, MEK, strong acids and bases are not advised as they can cause a significant decrease in mechanical properties..

Chemical compatibility of Rigid Pro 3D-printing resin

Chemical compatibility of 3D-printed test specimen from Rigid Pro resin can be found below.

Fuel, petrol and diesel resistant and compatible 3D-printing photopolymer resin

As seen above, all tested 3D-printing photopolymer resins can be used in combination with fuel / petrol and diesel. Depending on your application, a tough, flexible, rigid or composite part can be used. contact us at info@liqcreate.com for more information or advice on the best type of material for your application.

Compatibility with R1234yf and R123A refrigerants.

R1234yf is the new refrigerant for passenger cars, introduced in 2011 in a number of new car models. R134a and R1234yf are very similar, however, R1234yf was created as a more environmentally friendly replacement to R134a. How well do resin 3D-printed parts work with Tetrafluoropropene refrigerants like R123A and R1324yf? A leading company specialized in refrigeration systems tested two Liqcreate resins with these refrigerants.

The tests were done following standard protocols. The 3D-printed prototypes were placed in an autoclave filled with various combinations of refrigerants and oils. The 3D-printed parts stayed in a temperature chamber at exactly 90°C for a week. Before the start of the test, the parts were weighed, and the diameters measured.

The filling compositions were:

| Nr. | Refrigerants | Oils |

| 1 | R1234yf | PAG |

| 2 | R1234yf | POE |

| 3 | R134a | PAG |

| 4 | R134a | POE |

Results of chemical compatibility with R134a and R1234yf on 3D-printed parts

Average values over this period:

| Combination | Material | Weight change | Dimensional change |

| R1234yf / PAG | DeepBlue | + 2,284 % | + 0,271 % |

| R1234yf / PAG | Strong-X | n/a | n/a |

| R1234yf / POE | DeepBlue | + 2,698 % | + 0,271 % |

| R1234yf / POE | Strong-X | + 2,013 % | + 0,014 % |

| R134a / PAG | DeepBlue | + 5,861 % | + 1,354 % |

| R134a / PAG | Strong-X | + 2,731 % | + 0,881 % |

| R134a / POE | DeepBlue | + 5,321 % | + 1,014 % |

| 134a / POE | Strong-X | + 2,985 % | + 1,018 % |

The Liqcreate engineers would like to thank the external engineers for testing and sharing the results.

What about other resins and chemical compatibility and chemical compatibility with different chemicals?

The currently tested resins and chemicals are good selection of industrial chemicals and resins available from Liqcreate. If you are interested in chemical resistant and chemical compatibility of other Liqcreate resins, send us an e-mail with your question at info@liqcreate.com

Conclusion

The results show that Strong-X and Deep Blue have excellent compatibility with all tested chemicals. If a tougher, chemical resistant resin is required, Clear Impact is advised. Tough-X and Flexible-X are more critical with some chemical solutions and are therefore not advised for prolonged exposure to ethanol, methyl ethers, Methyl Ethyl Keton and Sodium Hydroxide.

Before using printed parts for your project, it is important to assess the exact conditions that the parts will be exposed to. Furthermore post-curing is of great importance to get good chemical compatibility.

All that remains is to wish you good luck with your project. If there are any questions, please contact Liqcreate: info@liqcreate.com.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Materials →

Find your chemical resistant and chemical compatible and chemical resistant 3D-print resins.

Deep Blue

Liqcreate Deep Blue is a general purpose photopolymer for DLP and SLA technologies in the range of 385 – 405nm. Parts created with Liqcreate Deep Blue have a rigid character and its low shrinkage and high shape retention make this material perfect for the production of functional prototypes. The aesthetically pleasing blue color, low odor and overall properties make the material perfect for rapid manufacturing and prototyping in the prosumer market. Deep Blue is the first choice in chemical compatible and chemical resistant 3D-print resins.

Key benefits |

3D-Printer compatibility |

| · Smooth surface finish | · Atum3D DLP Station 5 |

| · High accuracy | · Formlabs Form2 |

| · Excellent chemical compatibility | · Sprintray Moonray S & D |

| · Low shrinkage | · Cubicon Lux HD |

| · High translucency | · And many more |

Composite-X

Liqcreate Composite-X is an extremely rigid and high performance reinforced nano-micro composite resin for SLA, DLP & LCD / MSLA in the range of 385 – 420nm. Perfect for rapid tooling, wind tunnel testing, medical modeling and industrial applications.

Liqcreate Composite-X is one of the stiffest and strongest material available in the market. It has a flexural modulus over 9000 MPa and a flexural strength of 150 – 170 MPa. The material can be used after UV-post curing, or the properties can be boosted with a thermal cure. This material has features like excellent chemical resistance, high strength and high stiffness.

Key benefits |

3D-Printer compatibility |

| · High rigidity | · Phrozen3D Series |

| · High strength | · Atum3D DLP Station 5 |

| · Good chemical compatibility | · Elegoo & Anycubic series |

| · Good chemical resistance | · And many more |

| · Extremely low shrinkage |

Strong-X

Liqcreate Strong-X is one of the strongest materials available in the market. Its flexural strength of 135MPa is comparable to industry’s leading dual-cure cyanate ester resins. Liqcreate Strong-X is easy to use on all open source SLA and DLP 3D-printers in the range of 385 – 405nm and only requires UV post-curing. This material has excellent features like high strength, high stiffness and high temperature resistance which makes it ideal for injection molding and heavy duty applications.

Key benefits |

3D-Printer compatibility |

| · High strength | · Epax3D Series |

| · High temperature resistance | · Formlabs Form2 |

| · Good chemical compatibility | · Asiga & Anycubic series |

| · Low shrinkage | · And many more |

[1] https://wickedengineering.com/